Tech. Dok. / L23 880 02 / 01.00.02 © MICHAEL WEINIG AG

Maintenance and care

9-6 Profimat 23 E

Maintenance work

Belt tension of the spindle drives

Care must be taken to ensure that the belt is

always correctly tensioned. An incorrectly

tensioned belt can result in damage to the machine

and/or tools.

The belt tension must be checked every week or

when changing belts and the belt retensioned if

necessary.

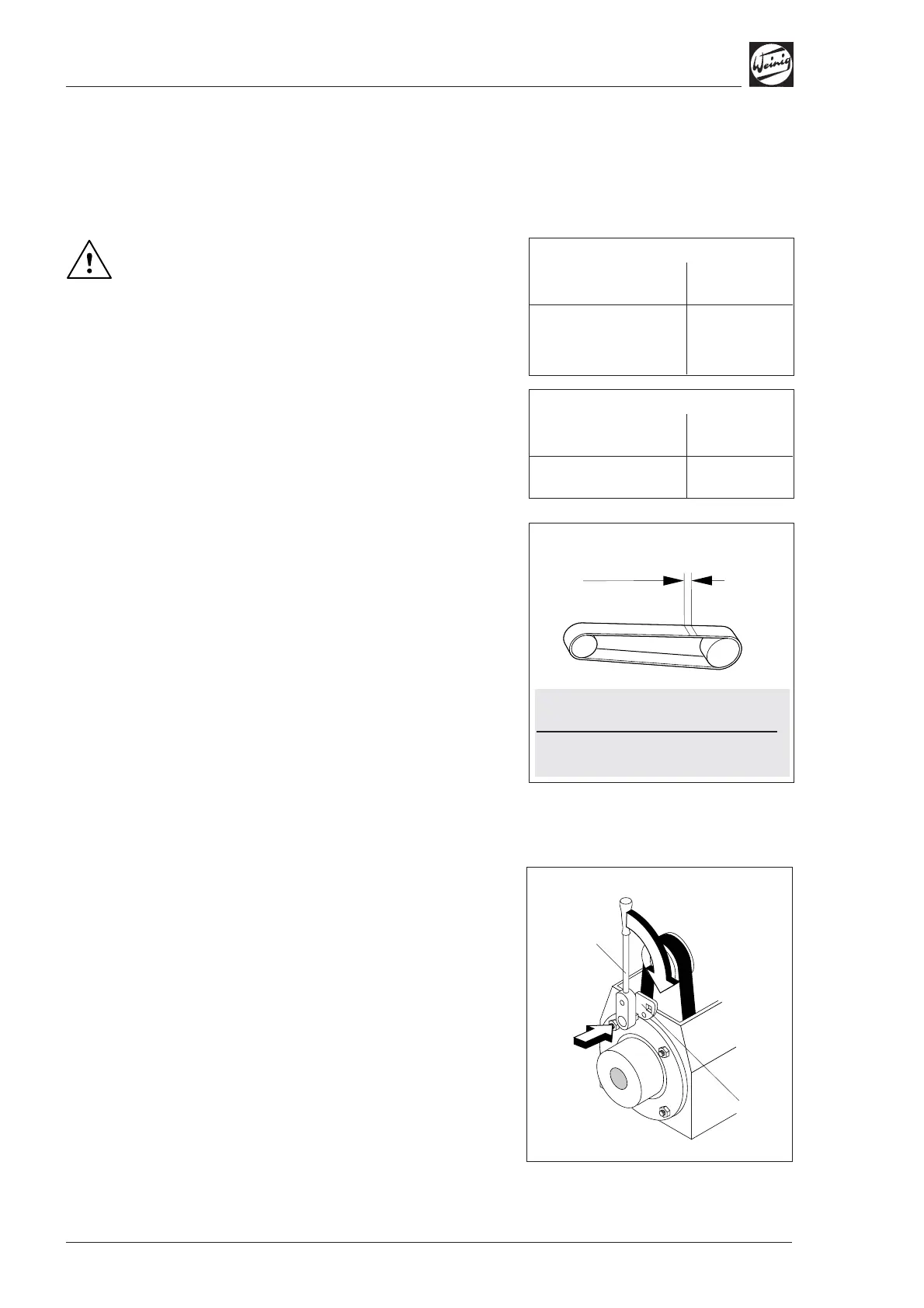

• Make two marks 200 mm apart on the

untensioned belt.

• Tension the belt and check the elongation.

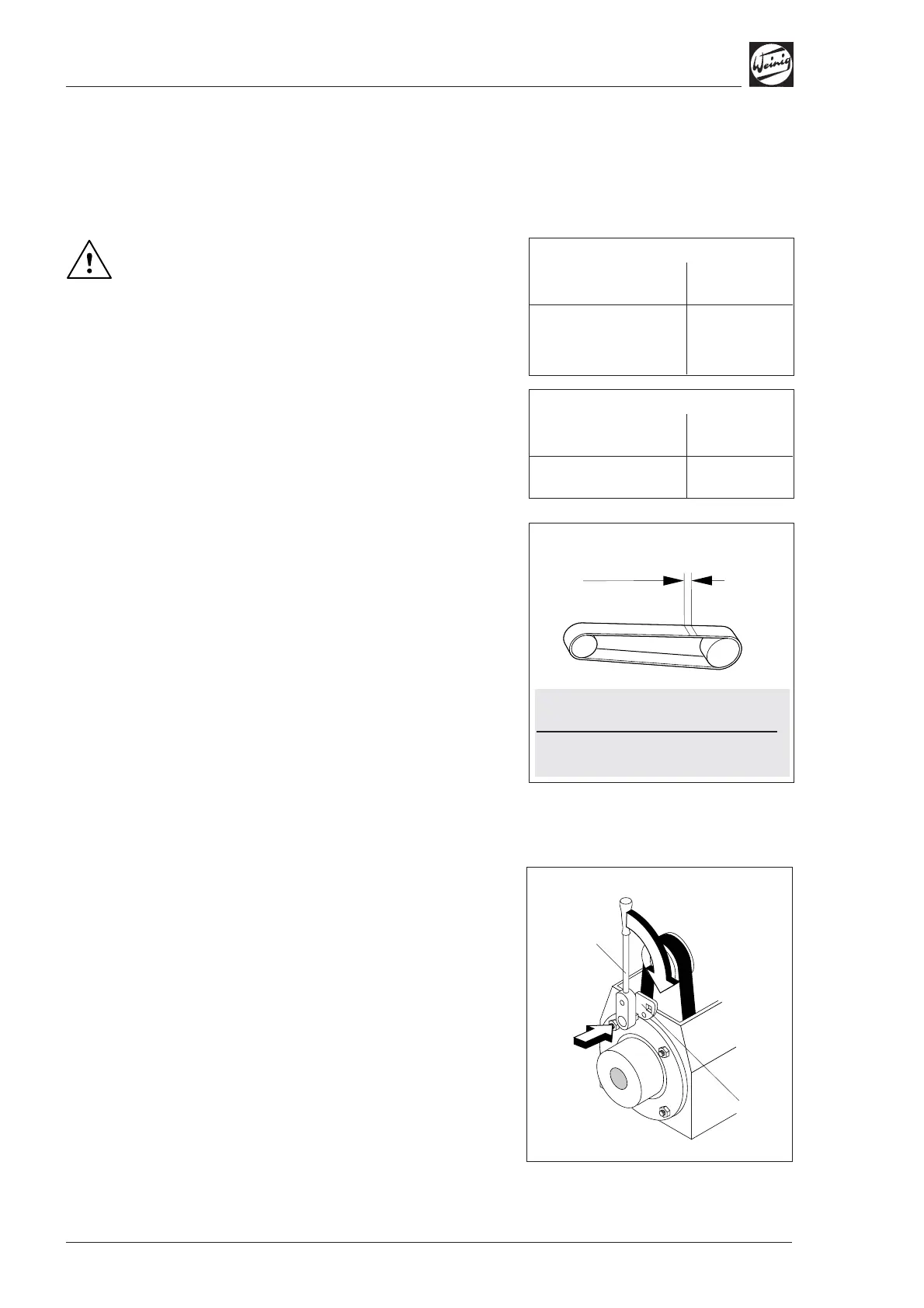

Horizontal spindles:

• Release clamping screws on motor.

• Insert wrench (1) in housing, fit ratchet (2) in

wrench and tension belt.

• Retighten clamping screws on motor.

Vertical spindles:

The belt is tensioned continuously by a

spring tensioner.

• Remove cover on front of machine in order to

reach the spring tensioner when changing belts.

(2)

(1)

Marks 200 mm

Dehnung 1.0 – 1.4 mm

Marks

after elongation 201 – 201.4 mm

200 mm + elongation

Belt type NE 22 + NE 26

Motor output

(kW)

4 5.5 7.5

11 15 18.5 22

Elongation

(%)

0.5 + 0.2

0.8 + 0.2

Belt type NE 18

Motor output

(kW)

15 18.5 22 30 37

Elongation

(%)

0.5 + 0.2

Example for belt type:

NE 22 5.5 kW

Consult Weinig if other belt

types are used!

Loading...

Loading...