Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

Tools

3-2 Profimat 23 E

Fitting tools

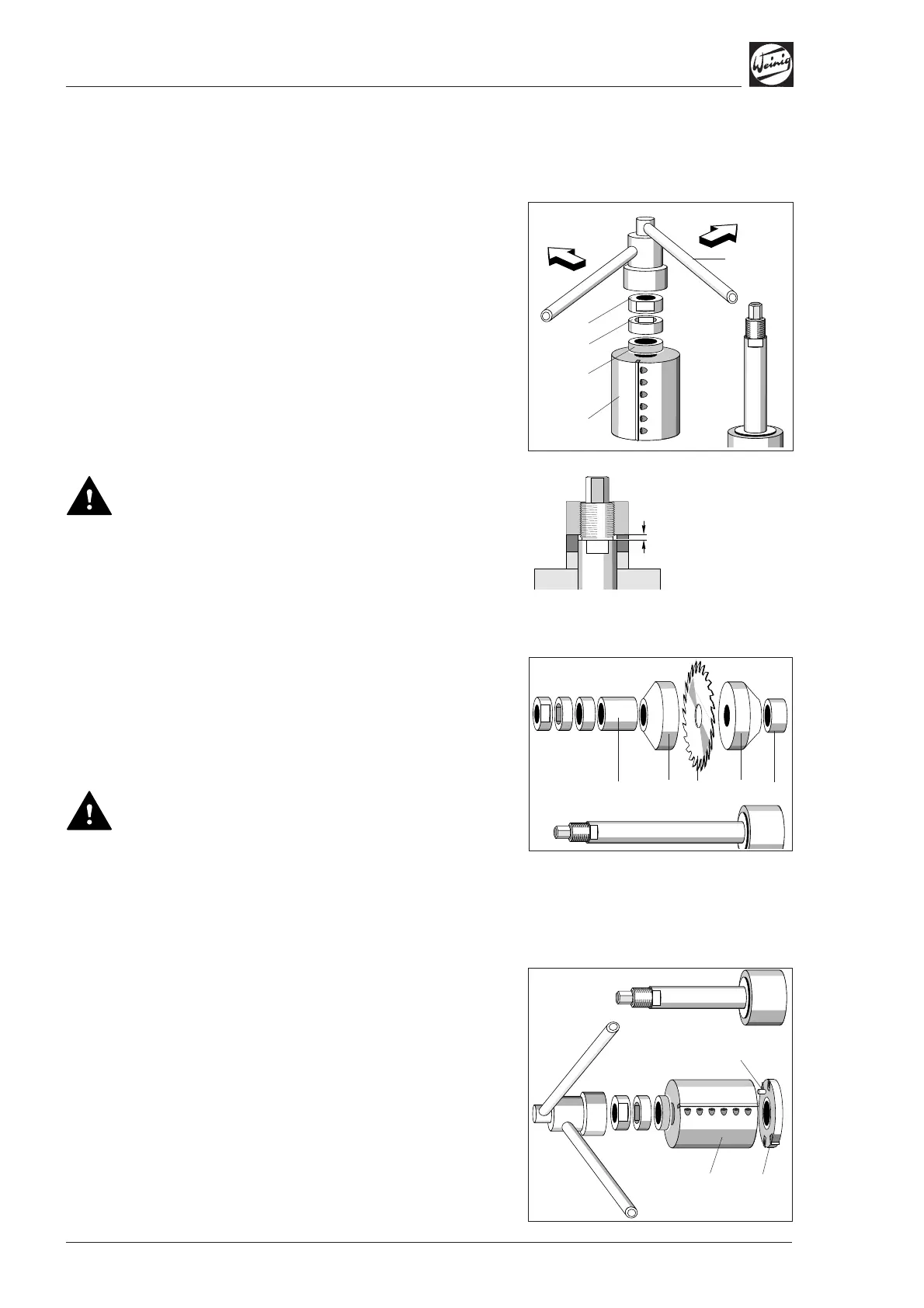

Planing / profile tool

• Planing tool (2), spacer rings (3), safety locking

collar (4) and spindle nut (5).

• Tighten spindle nut. Always use a double-

ended open-jawed wrench (1) for this purpose.

• The arrows in the diagram illustrate the

direction of action for tightening the spindle

nut.

The safety collar must protrude at least 1 mm

(0.040") beyond the spindle thread, otherwise

the tool cannot be tightened so that it is axially

secure and can spin on the spindle.

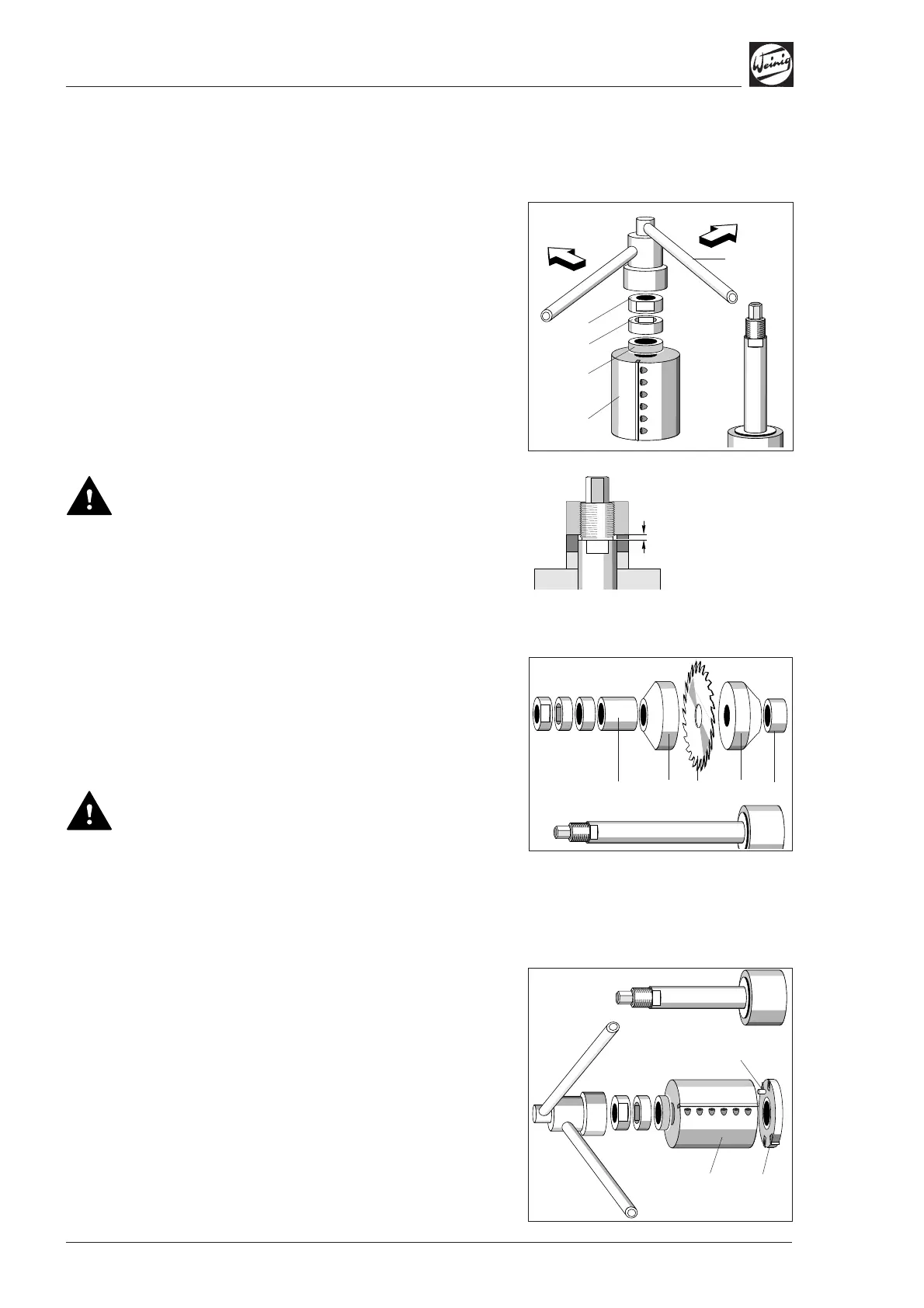

Saw blade on horizontal spindles

• Roughly determine the axial position of the saw

(3) by means of the spacer rings (1) and

clamping flanges (2) or clamping sleeve.

• Use axial spindle adjusting mechanism for

precise positioning.

Closely following the WEINIG fitter's

instructions. Use anti-kickback device.

Sawing unit for glazing beads

Note the information in the chapter "Machine

options".

Rebate cutter

The rebate cutter is axially clamped by the

planing tool.

• Mount rebate cutter (1) and planing tool (2) on

spindle with mutually offset cutting edges.

• Insert pin (3) on rebate cutter into

corresponding hole on cutterhead or gap under

gib.

(1)

(2)

(3)

(1)

(2)

(3)

(2) (1)

(2)

(5)

(4)

(3)

(1)

Loading...

Loading...