Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

Machine options

6-8 Profimat 23 E

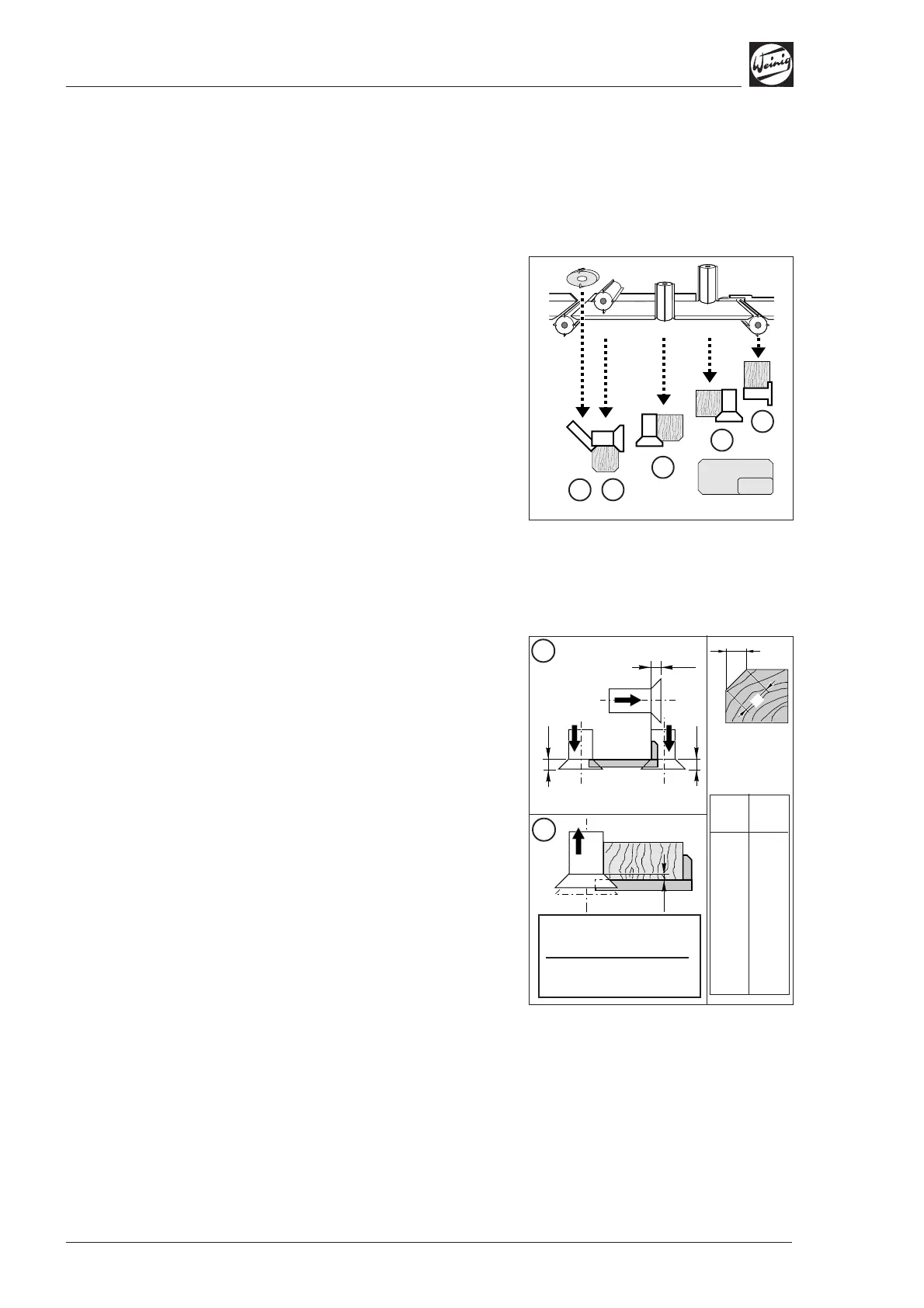

b = Bevel

width

l = Bevel

length

l

[mm]

1.4

2.8

4.2

5.6

7.0

8.4

9.8

11.2

12.6

14.0

b

[mm]

1

2

3

4

5

6

7

8

9

10

Cutter height 14 mm

– Bevel width (b) 5 mm

= Set value for numerical

indicator 9 mm

14

14

14

b

l

5

5

4

3

2

1

A

B

Bevel unit

Sequence of work, bevel unit and

bevel cutter

A workpiece is to be bevelled on four sides:

Step 1: Rebate groove

Step 2: Bevel bottom right

Step 3: Bevel bottom left

Step 4: Bevel top right

Step 5: Bevel top left by bevel unit

• Fit bevel cutter behind cutterheads as shown in

diagram.

Axial spindle setting when using

bevel cutters and bevel unit

A = Bevel width 0 mm:

The bevel cutters (tool height 14 mm) must be

axially positioned behind the fence or under the

table for a bevel size of 0 mm; in other words:

• Axially adjust right-hand, left-hand and top

spindle to set value = 14 mm as shown on

numerical indicator.

B = Bevel width x mm:

The bevel width (b) is determined by the operator

through axial adjustment of the spindles. The set

value for the numerical indicator is calculated as

follows:

• Set value = 14 mm – bevel width

Loading...

Loading...