Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

Machine options

6-12 Profimat 23 E

Groove guide

Function

Prevents short parts or parts with uneven ends

from running off the fence. Grooves are cut into

the workpiece by a groove cutter on the

straightening spindle. The timber is guided

through the machine by the grooves in the groove

bed. The outer right-hand groove (1) or the

second groove (2) acts as the main guide and

corresponds exactly with the width of the cut

groove. The other ridges are slightly narrower.

The guide grooves are planed off on the last

bottom spindle.

Radial basic setting of the edge-

jointing spindle

• Move the edge-jointing spindle approx. 0.2 mm

forwards in relation to the fence so that the

workpiece is guided in the groove and not along

the fence.

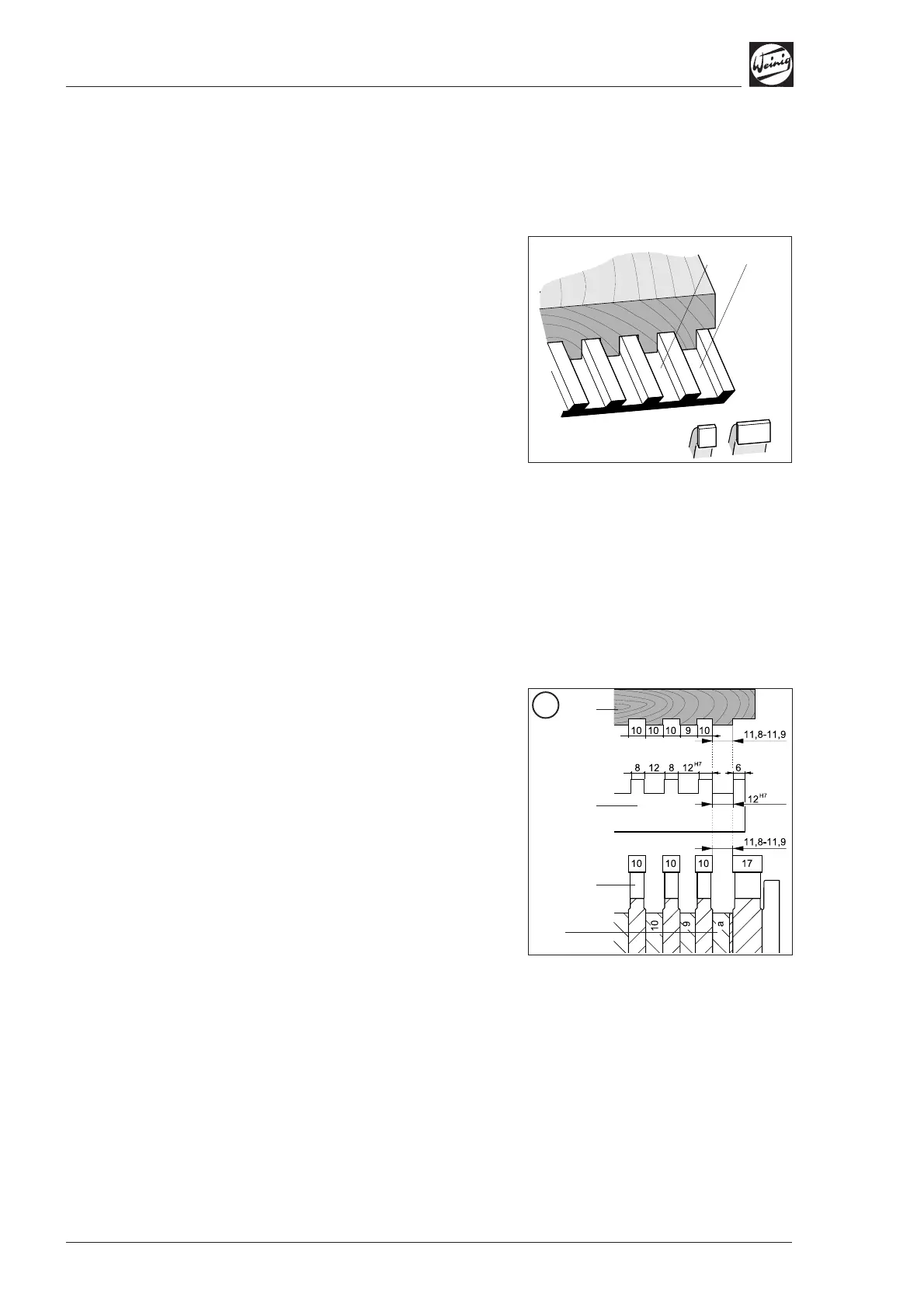

Axial specifications

The cutters must be assembled and mounted as

shown in Fig. A if the timber is guided in the first

groove.

(1) Timber

(2) Grooved table plate

(3) Groove cutters

Groove width (a) as a function of the

timber length

If the first ridge is cut off from the right on

account of the profile shape, the workpiece must

be guided by the second groove. The groove

cutters must be assembled as shown in Fig. B.

(1)

(2)

A

(1)

(2)

(3)

(a)

Loading...

Loading...