Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

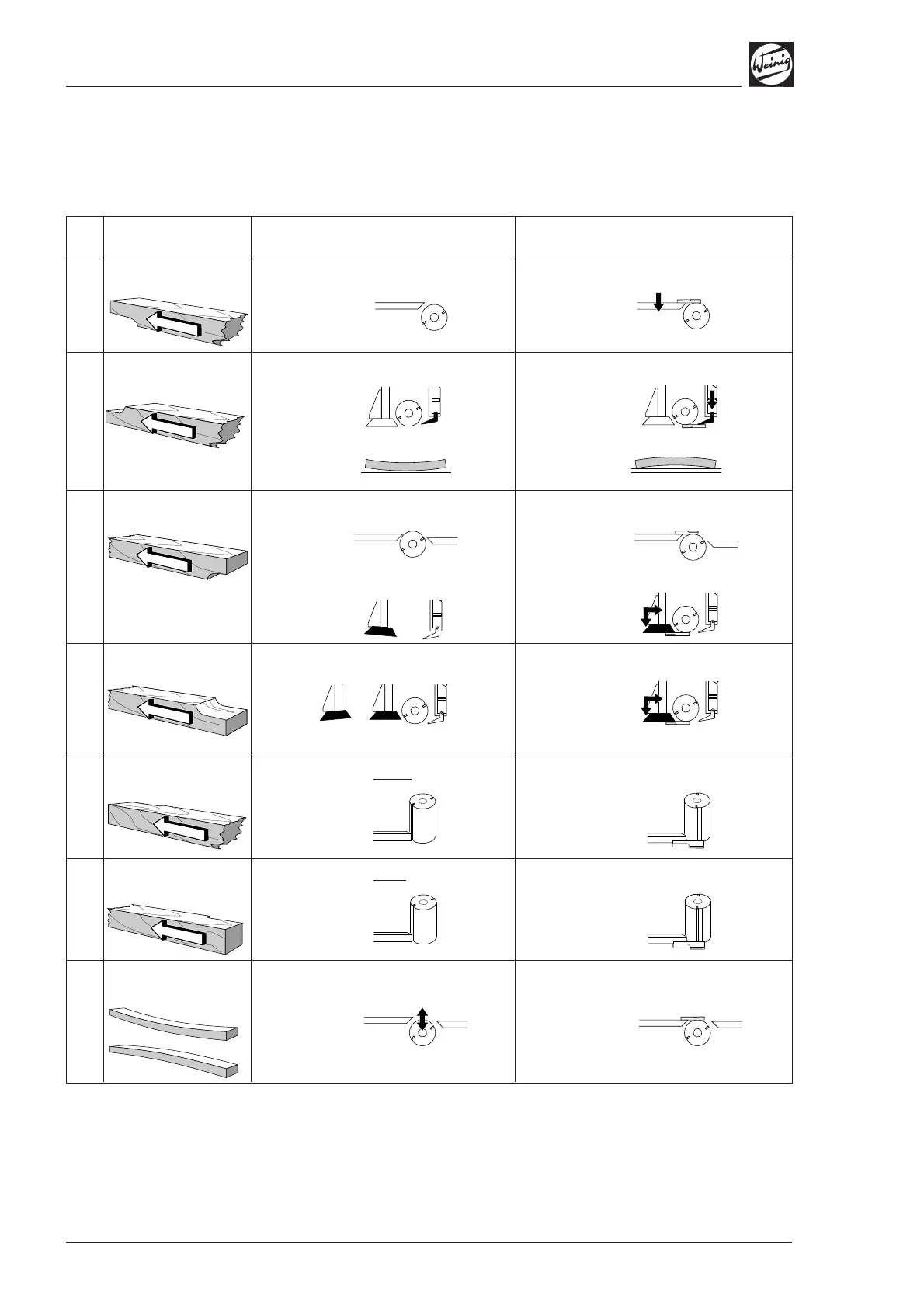

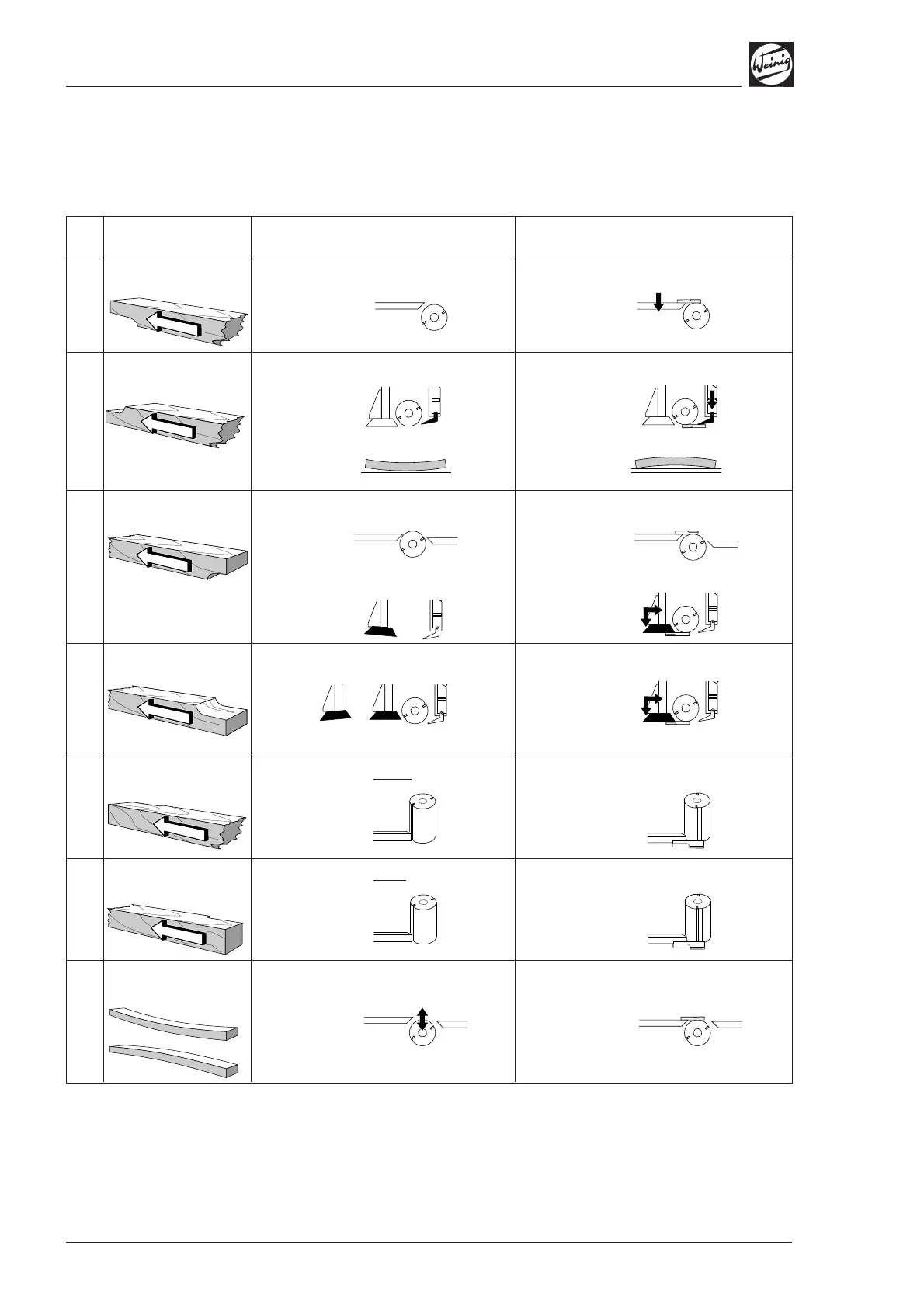

Troubleshooting

7-4 Profimat 23 E

Troubleshooting on workpiece

Possible cause

a) Tool on one of bottom spindles too low

or blunt

a) Hold-down ahead of top spindle

too high

b) Timber bowed or warped

a) Tool on bottom spindle too high

b) Pressure shoe behind top spindle not

parallel

a) Pressure shoe behind top spindle too

high or not parallel to table

b) Chipbreaker set too low

a) Tool positioned behind fence

a) Tool positioned ahead of fence

a) Tool on straightening spindle not set

accurately relative to table, or blunt

Remedy

a) Readjust tool relative to table or

resharpen

a) Readjust hold-down relative to tool

b) Place timber on table with hollow side

down

a) Readjust tool relative to table

b) Realign pressure shoe parallel to table

a) Realign parallel to table and readjust

pressure shoe relative to tool

b) Readjust chipbreaker

a) Readjust tool relative to fence

a) Readjust tool relative to fence

a) Readjust tool relative to table

No.

1

2

3

4

5

6

7

Fault

Snipes, leading end,

bottom

Snipes, leading end,

top

Snipes, trailing end,

bottom

Snipes, trailing end,

top

Snipes,

leading end, right

Snipes, trailing end,

right

Point/hollow joint

when straightening

Loading...

Loading...