Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

Machine options

6-6 Profimat 23 E

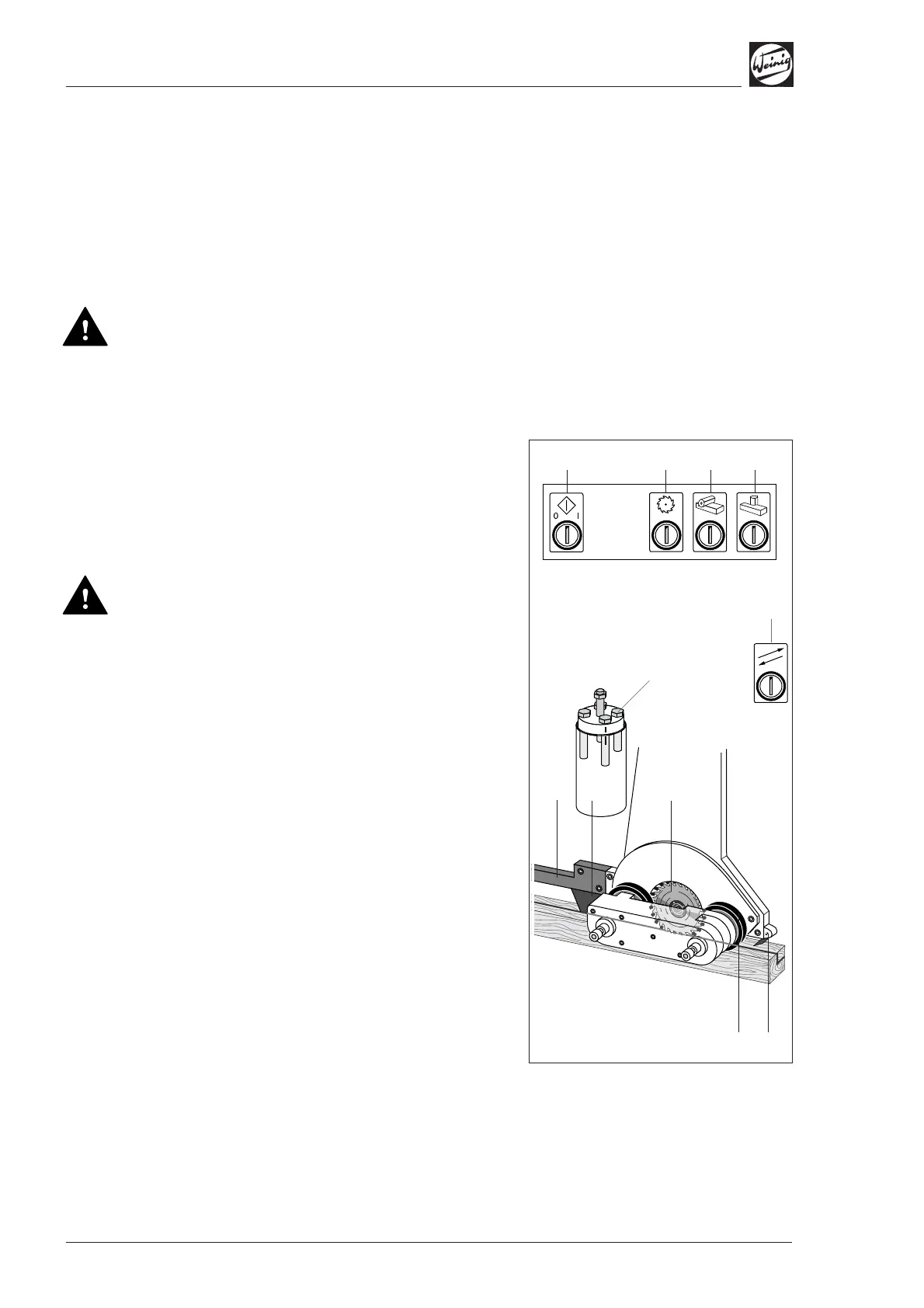

Sawing unit for glazing beads

Application

Cutting out glazing beads during window

production.

The safety instructions given by the WEINIG

service engineer during commissioning must

be observed when fitting saw blades and

setting the glazing bead saw.

Fitting the saw blade

• Fit saw blade (3) on flange and mount safety

collar. Fit clamping screw and tighten by hand.

• Hold clamping nut with size 50 fork wrench and

securely tighten clamping screw with hexagonal

socket wrench.

All guiding elements must be adjusted to the

clamped saw blade and the blade's freedom of

movement checked before switching on the

sawing unit.

Radial basic setting

• Adjust depth of penetration of saw blade via

turret (11). A number of depths can be set.

Axial basic setting

• The axial position of the saw blade in relation to

the machine fence must be set via the

counterscrew on the horizontal slide on the rear

of the machine.

Adjusting the guiding and safety

elements

• Align anti-kickback device (5), additional feed

rollers (4), splitting wedge (2) and guide rollers

for the glazing bead on guide beam (1) in

relation to the clamped saw blade as specified

by the WEINIG service enginer during

commissioning.

(1) (3)(2)

(4) (5)

(6) (8)(7)

(9)

(10)

(11)

Loading...

Loading...