Tech. Dok. / L23 880 02 / 01.00.02 © MICHAEL WEINIG AG

Basic setting

4-12 Profimat 23 E

Bottom spindle

Set chip removal

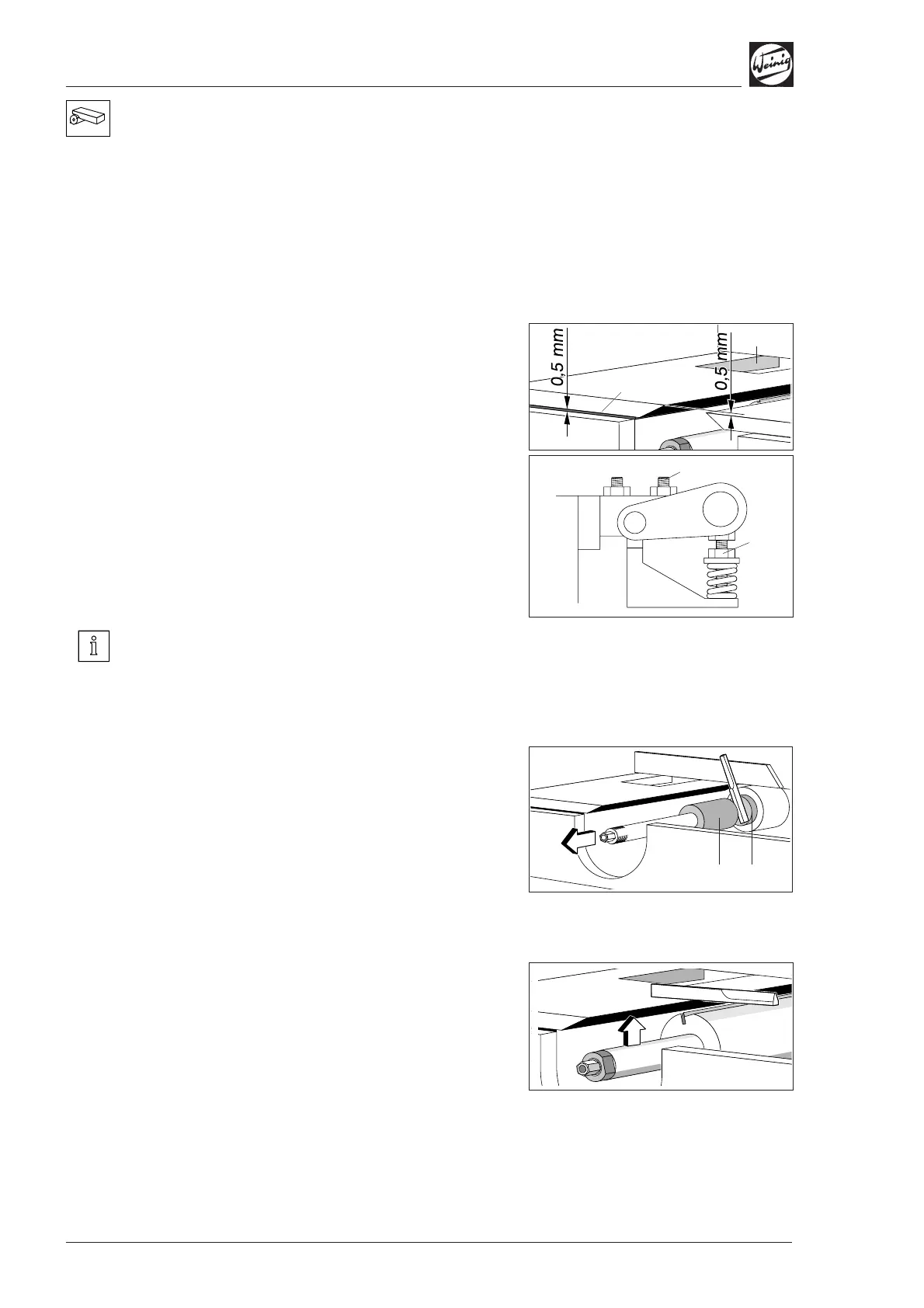

The table plate must be adjusted upwards after

the last bottom spindle so that the underside of

the timber can be finish-planed.

• Unscrew table plate.

• Place 0.5 mm (0.20") shim supplied between

base and table plate.

Chip removal is impossible without the shim.

Table roller

• Adjust table roller (2) to match table height.

On the rear of the table:

• Adjust table roller up/down by means of

adjusting screw (3).

• Adjust spring pressure via spring pressure

element (4) if necessary (set to basic position

by manufacturer).

If the spindle is set for chip removal, all spindles

must be raised in relation to the outfeed table by

the amount of chip removed.

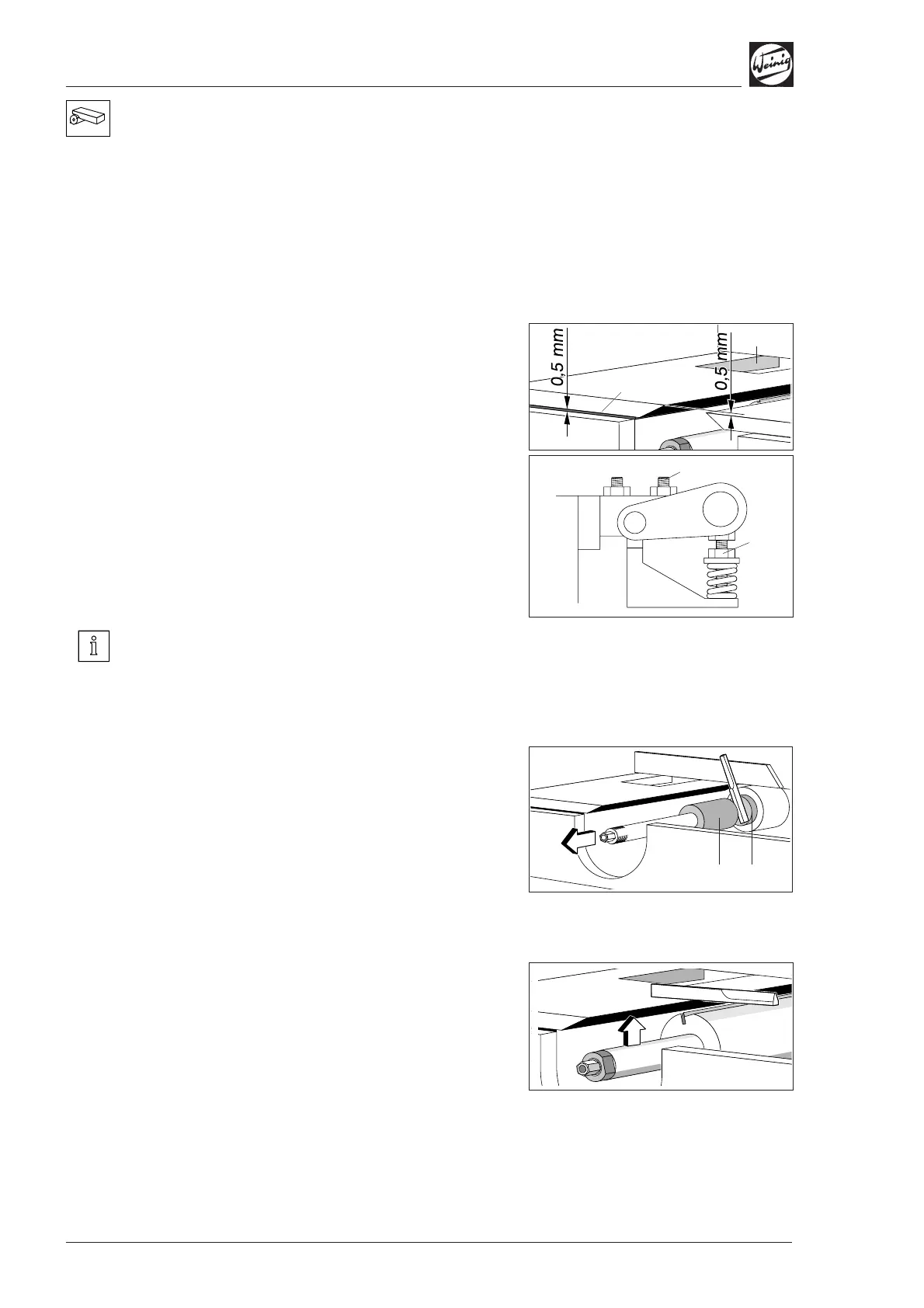

Axial basic setting

• Clamp setting straight edge between spacer

ring (1) 10.0 mm (0.394") and spindle ring (2)

63.0 mm (2.480").

• Release clamp and adjust spindle in axial

direction until setting straight edge is aligned

with fence.

• Set numerical indicator to 10.0 mm (0.394").

Radial basic setting

• Fit a dimensioned tool, radius 62.5 mm

(2.460") in this case.

• Place setting straight edge on outfeed table.

• Release clamp for spindle slide and adjust tool

in relation to setting straight edge.

• Set numerical indicator to 62.5 mm (2.460")

(see page 4-1).

(1)

(2)

(4)

(3)

(1)

(2)

Loading...

Loading...