Tech. Dok. / L23 880 02 / 01.00.02 © MICHAEL WEINIG AG

Maintenance and care

9-2 Profimat 23 E

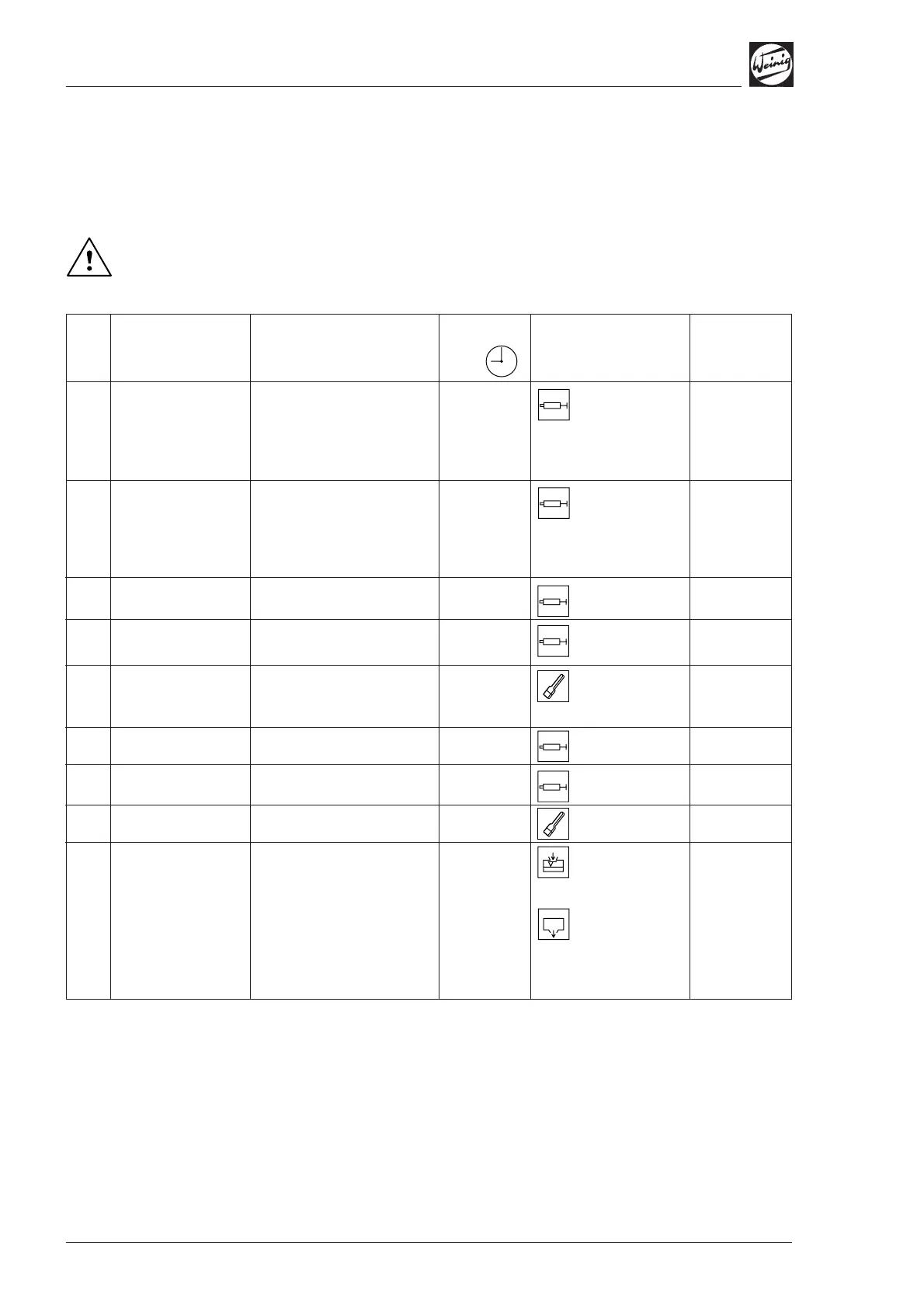

Lubricating

interval

40

160

160

480

480

480

480

480

160

500/2000

Lubrication and maintenance schedule

Lubrication

Only the lever-type hand gun without pressure gauge

(pressure indicator) supplied by WEINIG may be

used for lubrication.

Amount of lubricant

(1)

,

maintenance job

1 shot with lever-

type hand gun

1 shot with lever-

type hand gun

1 shot with lever-

type hand gun

1 shot with lever-

type hand gun

Grease lightly

1 shot with lever-

type hand gun

1 shot with lever-

type hand gun

Grease lightly

Up to oil viewglass

875 – 1125 ccm

Comments

Until grease

emerges

Until grease

emerges

Clean thoroughly

first

Clean thoroughly

first

Check for leaks

and oil level every

160 h, top up oil if

necessary

1st oil change after

500 h

2nd oil change

after 2000 h, then

every 2 years

Recommended lubricant or

equivalent product as specified in

table of comparable lubricants

SHELL ALVANIA GREASE G2

SHELL ALVANIA GREASE G2

SHELL ALVANIA GREASE G2

SHELL ALVANIA GREASE G2

SHELL ALVANIA GREASE G2

SHELL ALVANIA GREASE G2

SHELL ALVANIA GREASE G2

SHELL ALVANIA GREASE G2

SHELL OMALA 220

Lubricating points

CNC/ATS-controlled

spindles (optional) (not

illustrated)

– Transport slide

– Spindle slide

– Adjusting spindle

– Spindle nut

Dovetail guides

– All spindles except

ATS/CNC

– Glazing bead saw

(optional) (Second

lube nipple on rear of

machine (not illus.)).

Universal joint shafts

– Feed

Spindle nut

– Top spindle, transport

slide on feed beam

Adjusting spindles

– Horizontal spindles

– Vertical spindles

– Universal spindles

Infeed table

– Adjustments

Pressure element

– Top spindle

Worm gear (not illus.)

– Universal spindle

Gear mechanism

– Feed

Pos.

1

2

3

4

5

6

7

8

9

1)

Amount delivered by lever-type hand gun (Order No.: 00 309 091): 1.5 ccm/shot

Lubrication with central lubricating

panel for axial lubrication (optional)

The axial adjustments of the spindles are

lubricated via the central lubricating panel

(see overleaf). All other lubrication as above.

Loading...

Loading...