Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

Data, transport, start-up

8-11Profimat 23 E

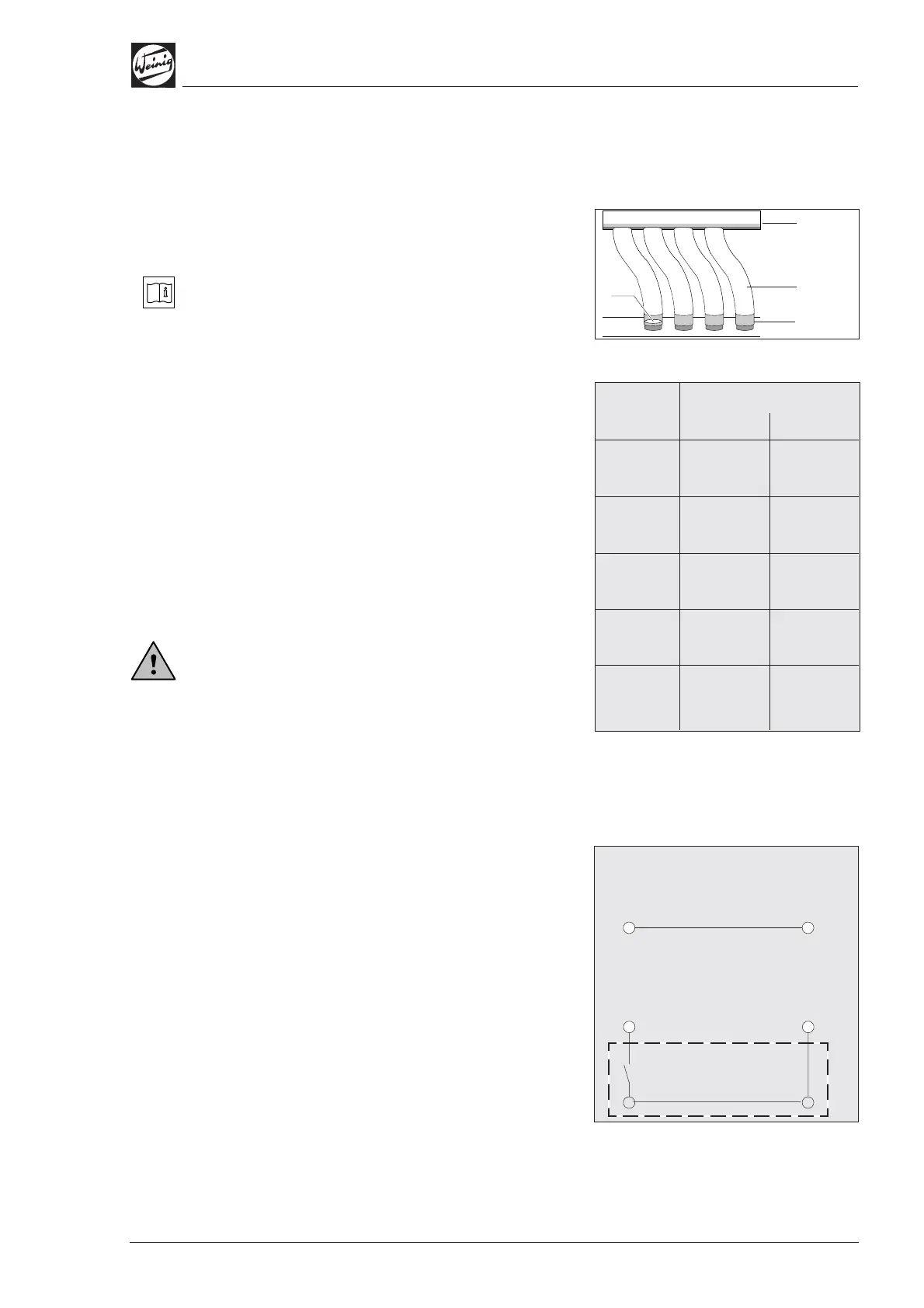

(3)

(1)

(2)

Dust extraction

• Install flexible hoses (3) between the dust

extraction hoods (1) and the dust manifold (2).

See installation diagram with regard to the outlet

diameter of the extractor hoods. The hose length

depends on the type of hose and on the spindle

travel.

The extraction system must generate an air

velocity of 30 – 34 m/s at the outlets of the

individual extractor hoods.

Due to pressure losses and the velocity of air, the

following negative pressures must be taken into

account in the machine:

a negative pressure of 1500 Pa at 30 m/s and

a negative pressure of 2000 Pa at 34 m/s.

Hoses with flame-retardant finish must be

used for the flexible connecting leads.

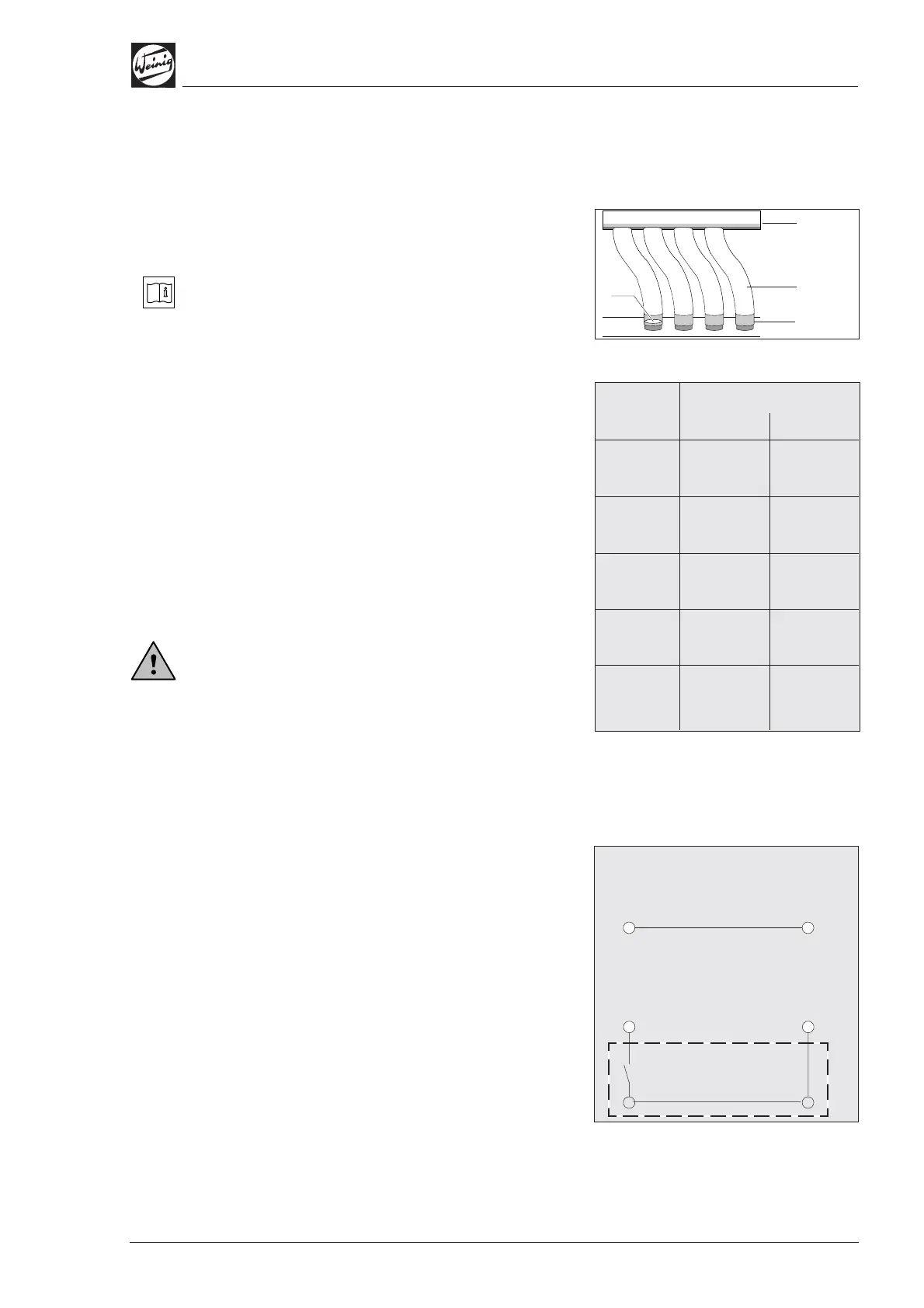

Electrical connection of the dust

extractor

If continuous feed is only to run when the

extraction system is on, terminals –X20 : 30.03

and –X20 : 30.04 in the control cabinet must be

connected to a floating contact in the extractor

control. The terminal labelling must be altered

accordingly.

The electrical connections for the dust extractor

must be connected by a qualified electrician.

Circuit diagram including extraction

Circuit diagram without including extraction

30.04

30.04

30.03

Jumper

X20 X20

30.03

X20 X20

Extractor "on"

min.

3400 m

3

/h

2160 m

3

/h

1680 m

3

/h

1260 m

3

/h

540 m

3

/h

Outlet

diameter

200 mm

160 mm

140 mm

120 mm

80 mm

max.

3850 m

3

/h

2450 m

3

/h

1920 m

3

/h

1380 m

3

/h

660 m

3

/h

Air requirement

Loading...

Loading...