Tech. Dok. / L23 880 02 / 01.00.02 © MICHAEL WEINIG AG

Basic setting

4-2 Profimat 23 E

Setting spindles

The tool must be set in relation to the following

fence or table in order to avoid snipes. The fol-

lowing example refers to the right-hand spindle:

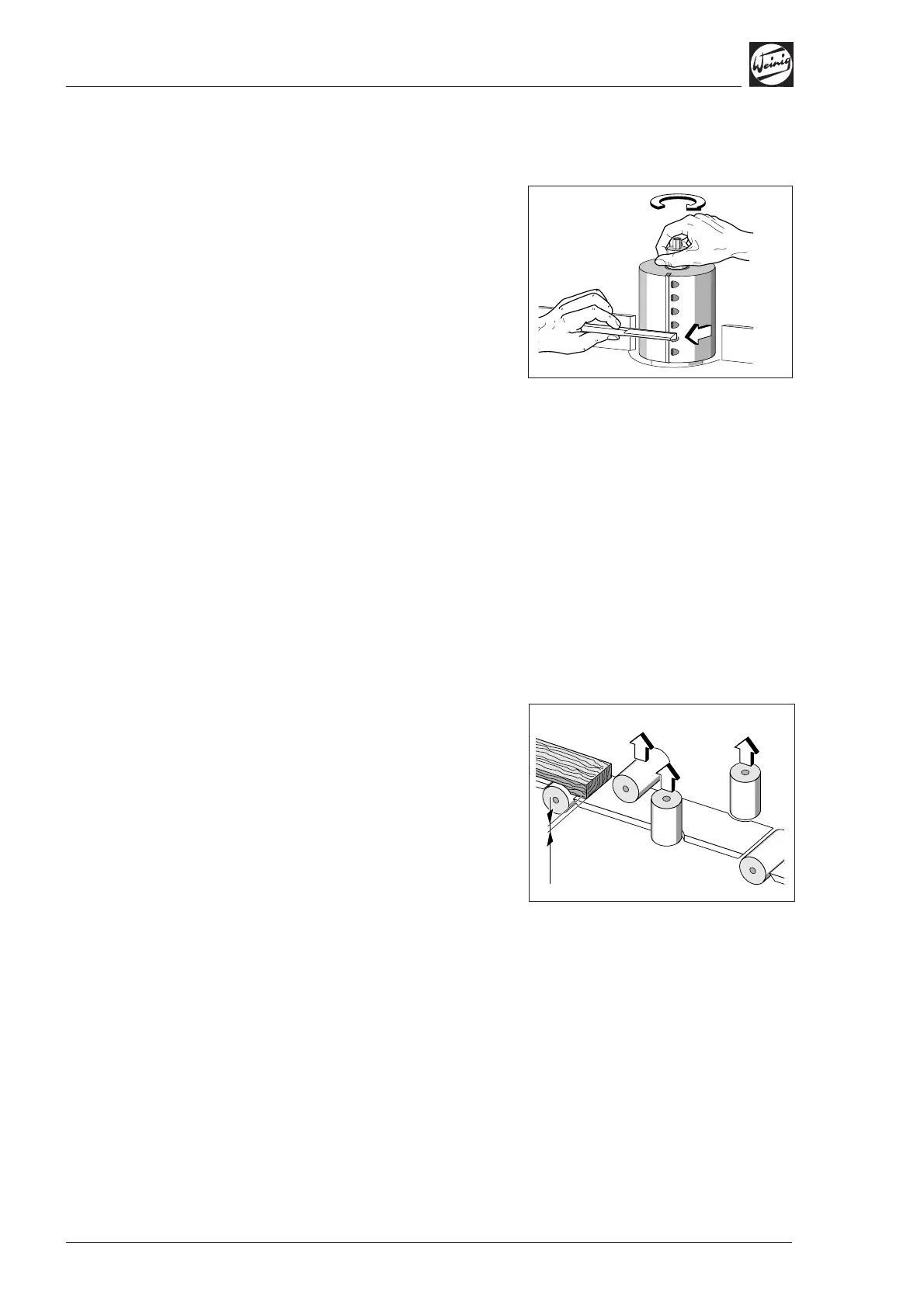

• Hold setting straight edge against fence and

adjust tool towards setting straight edge until at

least one cutting edge touches the bar. Turn the

tool by hand in the direction opposite to that of

cutting during the adjustment.

• The tool is correctly set when the rubbing

movement of the cutting edge against the setting

straight edge can be faintly felt but not heard.

• Set the mechanical counter in this position.

Pressure elements

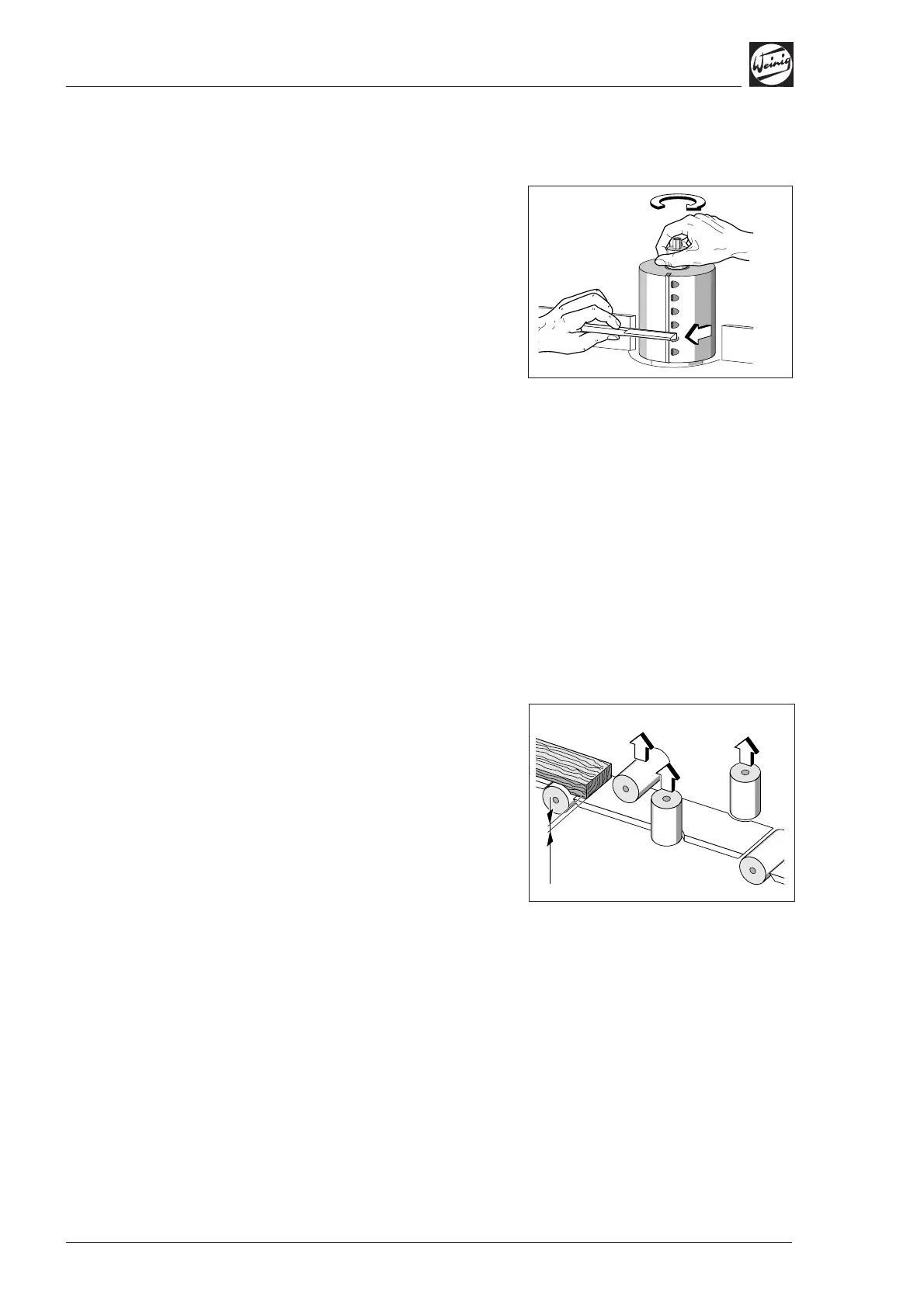

When the tools have been set to their basic

position, the pressure elements and table plates

must be set as close as possible to the largest tool

cutting circle.

Note the following point for the

bottom spindle:

If a chip is removed on the last bottom spindle, this

must be taken into account on the top spindle when

setting the numerical indicators, e.g. 0.5 mm

(0.020").

Height correction

The chip removal in axial direction must be taken

into account, e.g. 0.5 mm (0.020"), when

profiling with the vertical spindles.

0,5

0,5

0,5

0,5

Loading...

Loading...