Tech. Dok. / L23 880 02 / 05.99.01 © MICHAEL WEINIG AG

Setting up profiles

5-5Profimat 23 E

63

15

22

78

56

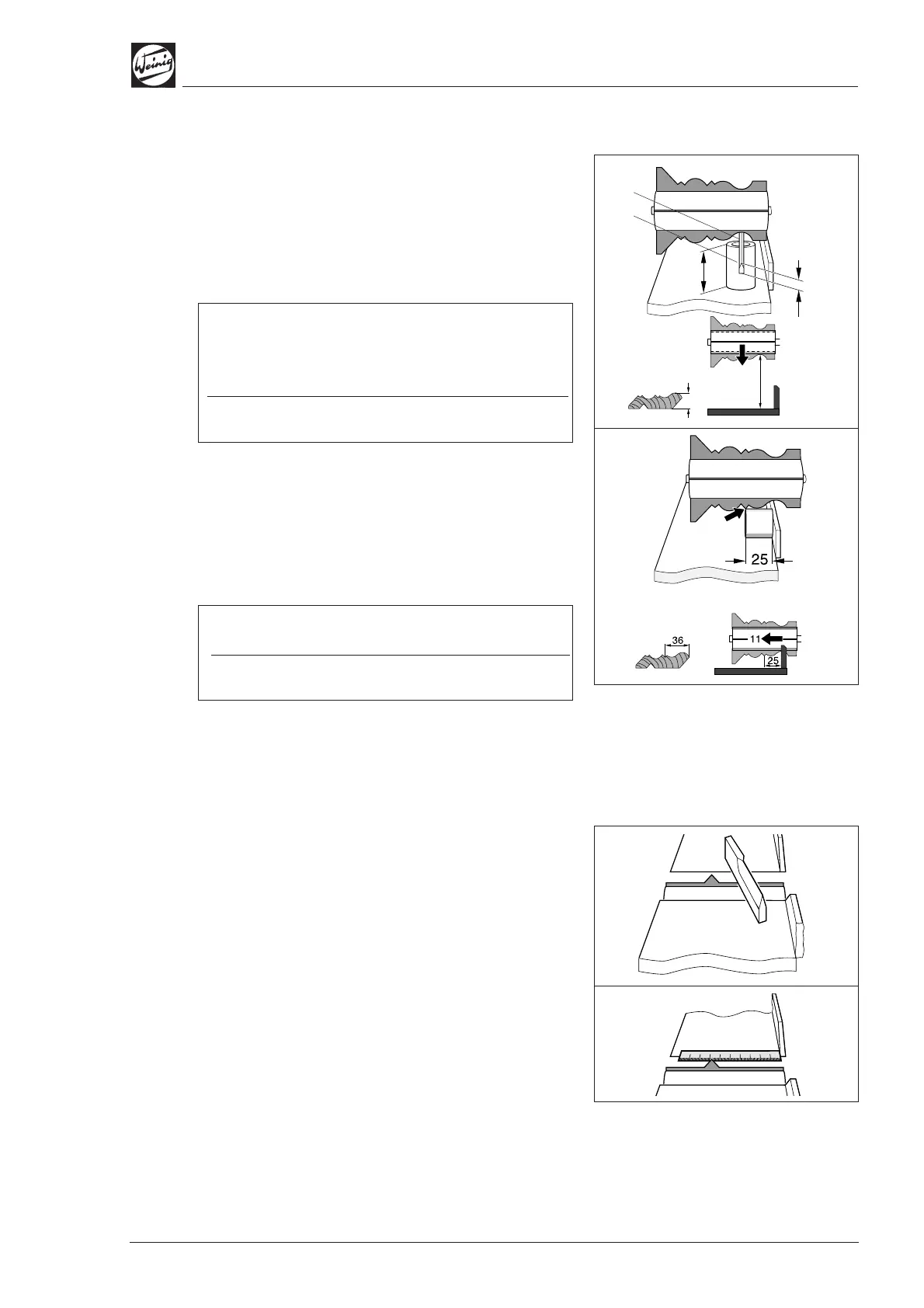

Top spindle

Example – radial

• Place spacer ring (1) and setting straight edge

(2) on table. Adjust tool in relation to setting

straight edge.

• Calculate workpiece height:

• Move spindle down by 56.0 mm (2.205").

Example – axial

• Place spacer ring against fence. Set tool against

edge of spacer ring.

• Calculate reference value of workpiece.

• Move tool 11.0 mm (0.433") forwards.

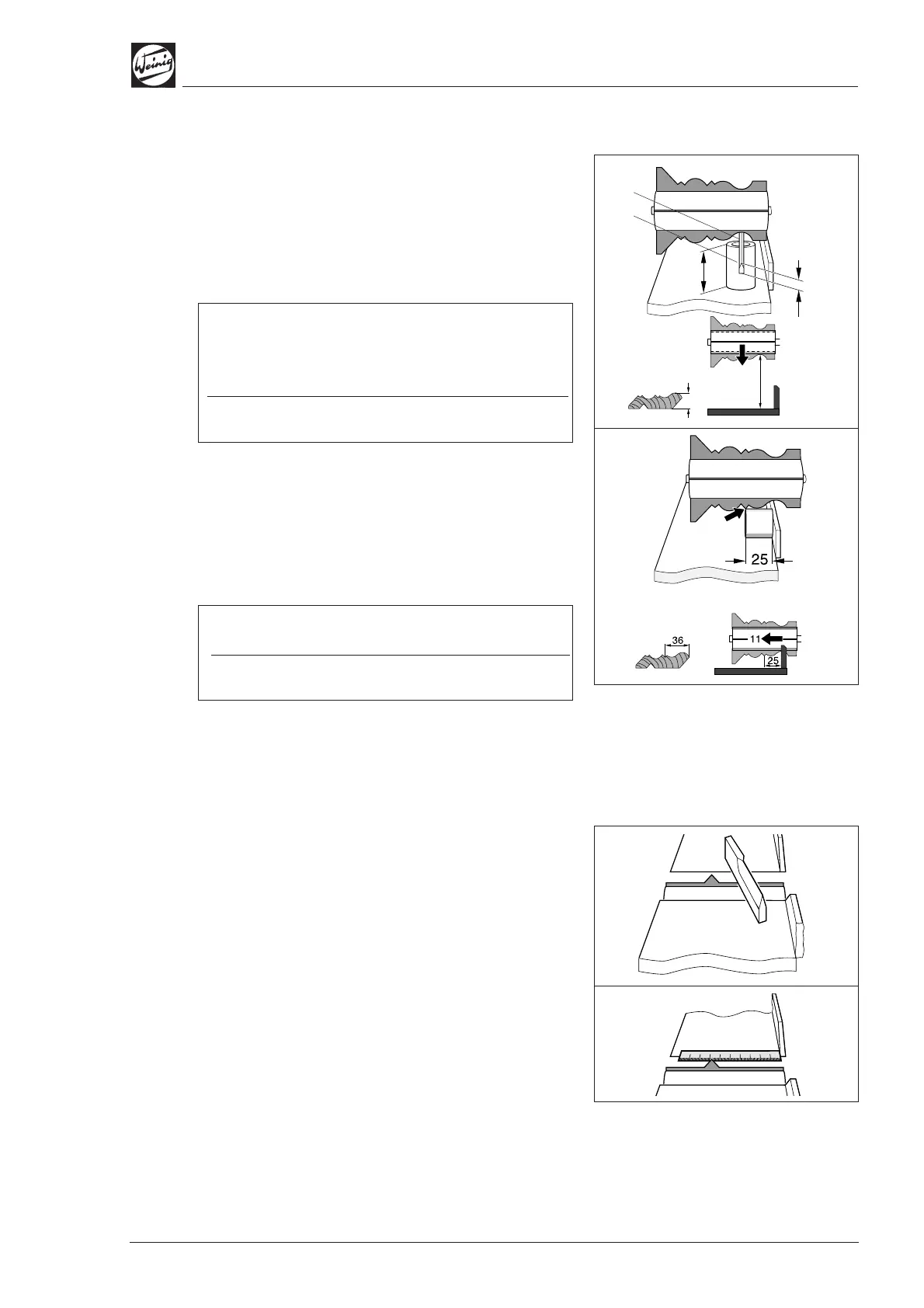

Bottom spindle

Example – radial

• Set smallest cutting circle in relation to setting

straight edge on the outfeed table.

Example – axial

• Place steel ruler against the fence after the

spindle and set profile tip to 57 mm (2.244").

Test run

• After a trial run, correct spindle setting as

described in the chapter entitled "Set-up

variation, planing a test piece".

Height of setting

straight edge...................... 15.0 mm (0.590")

+ Height of spacer ring ........ 63.0 mm (2.480")

– Ref. value of workpiece.... 22.0 mm (0.866")

= Spindle correction............. 56.0 mm (2.205")

Height of spacer ring ....... 25.0 mm (0.984")

– Ref. value of workpiece... 36.0 mm (1.417")

= Spindle correction............ 11.0 mm (0.433")

(1)

(2)

Loading...

Loading...