5 Operation

5.5.2 Reference Offset Adjustment

5-44

(2) Parameter Setting

Using Pn400, set the analog voltage level for the torque reference (T-REF) that is necessary to operate the ser-

vomotor at the rated torque.

Note: A torque reference above the rated torque can be applied but it may cause an overload (high load) alarm (A.710) or

overload (low load) alarm (A.720) if excessive torque is output for a long time. Refer to 9.1.2 Troubleshooting of

Alarms.

5.5.2 Reference Offset Adjustment

In

torque

control, the servomotor may rotate at a very low speed with a voltage reference of 0 V. This occurs

because the internal reference in the multi-winding drive unit has a slight offset of a few millivolts. It is called

"offset."

If the servomotor rotates at a very low speed, the offset needs to be eliminated with the offset adjustment func-

tion.

Use either automatic adjustment or manual adjustment. Automatic adjustment uses the automatic adjustment

parameter for reference offset (Fn009). Manual adjustment uses the manual adjustment parameter for refer-

ence offset (Fn00B).

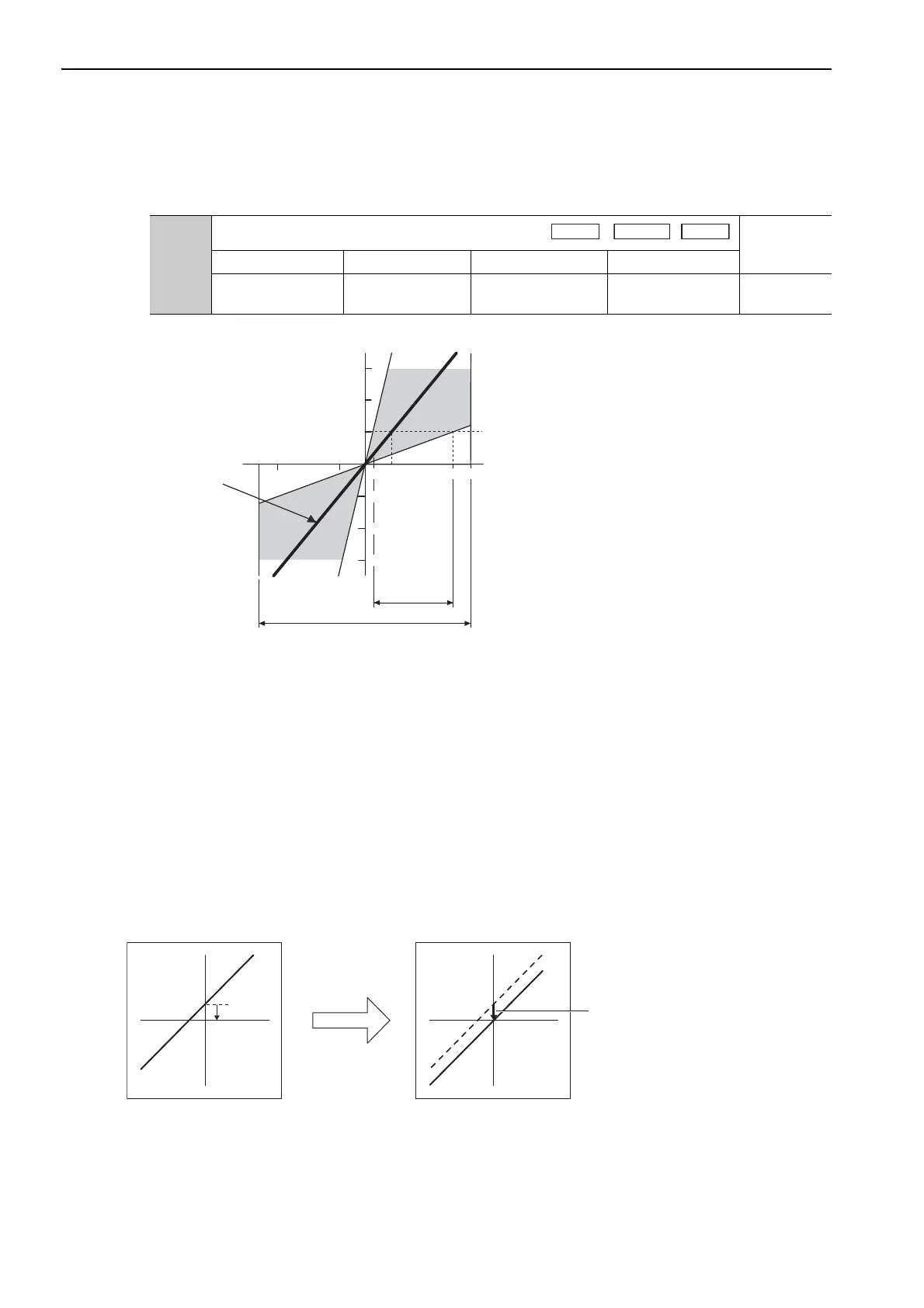

Pn400

Torque Reference Input Gain

Classification

Setting Range Setting Unit Factory Setting When Enabled

10 to 100 0.1 V/rated torque

30

(Rated torque at 3.0 V)

Immediately Setup

Speed

Position

Torque reference voltage (V)

(Rated torque)

300

200

100

-300

-200

-100

1 3 10 12

0-3-10-12

Setting range

(1.0 to 10.0 V)

Factory Setting

Output torque (%)

Input voltage range (0 to ±12 V)

Output torque Output torque

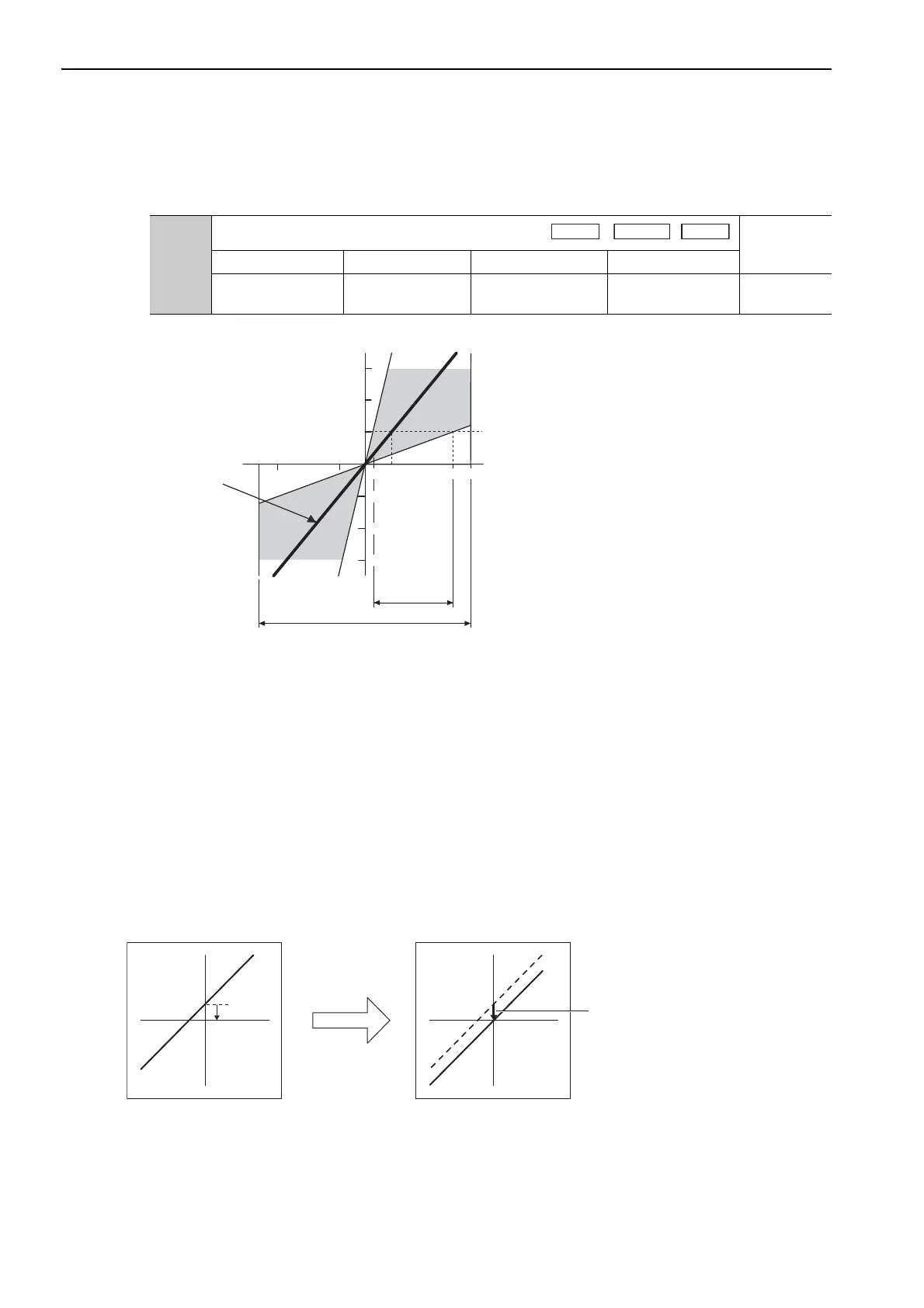

Offset

Offset adjustment

Torque

reference

voltage

Torque

reference

voltage

The offset is adjusted in the multi-winding

drive unit.

Offset Adjustment Range: -127 to +127

(Torque Reference: -1905 mV to 1905 mV

Offset Setting Unit: 15.0 mV)

Loading...

Loading...