6.7 Compatible Adjustment Function

6-51

6.7.6 Torque Reference Filter

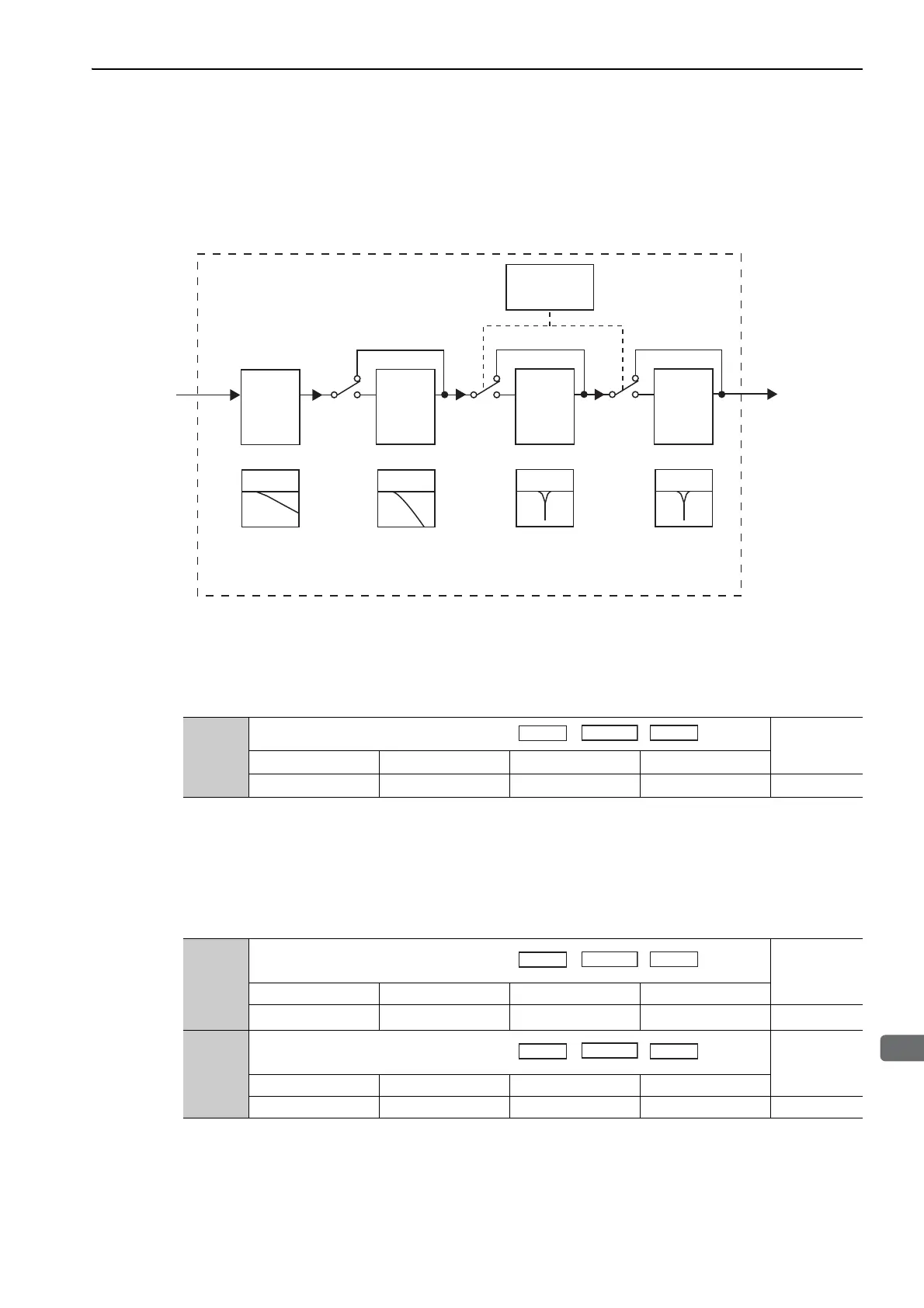

As shown in the following diagram, the torque reference filter contains first order lag filter and notch filters

arrayed in series, and each filter operates independently. The notch filters can be enabled and disabled with the

Pn408.

(1) Torque Reference Filter

If you suspect that machine vibration is being caused by the servo drive, try adjusting the filter time constants

with Pn401. This may stop the vibration. The lower the value, the better the response will be, but there may be

a limit that depends on the machine conditions.

Torque

Reference Filter Setting Guide

Use the speed loop gain (Pn100 [Hz]) and the torque filter time constant (Pn401 [ms]) to set the torque refer-

ence filter.

Adjusted value for stable control: Pn401 [ms] ≤ 1000/ (2π × Pn100 [Hz] × 4)

Critical gains: Pn401 [ms] < 1000/ (2π × Pn100 [Hz] × 1)

∗

The filter is disabled if 5000 is set.

Torque

reference

before

filtering

Torque Related

Function Switch

Pn408

Notch filter Notch filter

First order lag filter

Torque

reference

after

filtering

Second order lag filter

2nd

Notch

Filter

(Pn40C,

Pn40D, and

Pn40E)

1st Notch

Filter

(Pn409,

Pn40A,

and Pn40B)

* The 2nd torque reference filter is enabled when Pn40F is set to a value less than

5000 and disabled when Pn40F is set to 5000 (factory setting).

*

Torque

Reference

Filter

(Pn401)

2nd

Torque

Reference

Filter

(Pn40F,

Pn410)

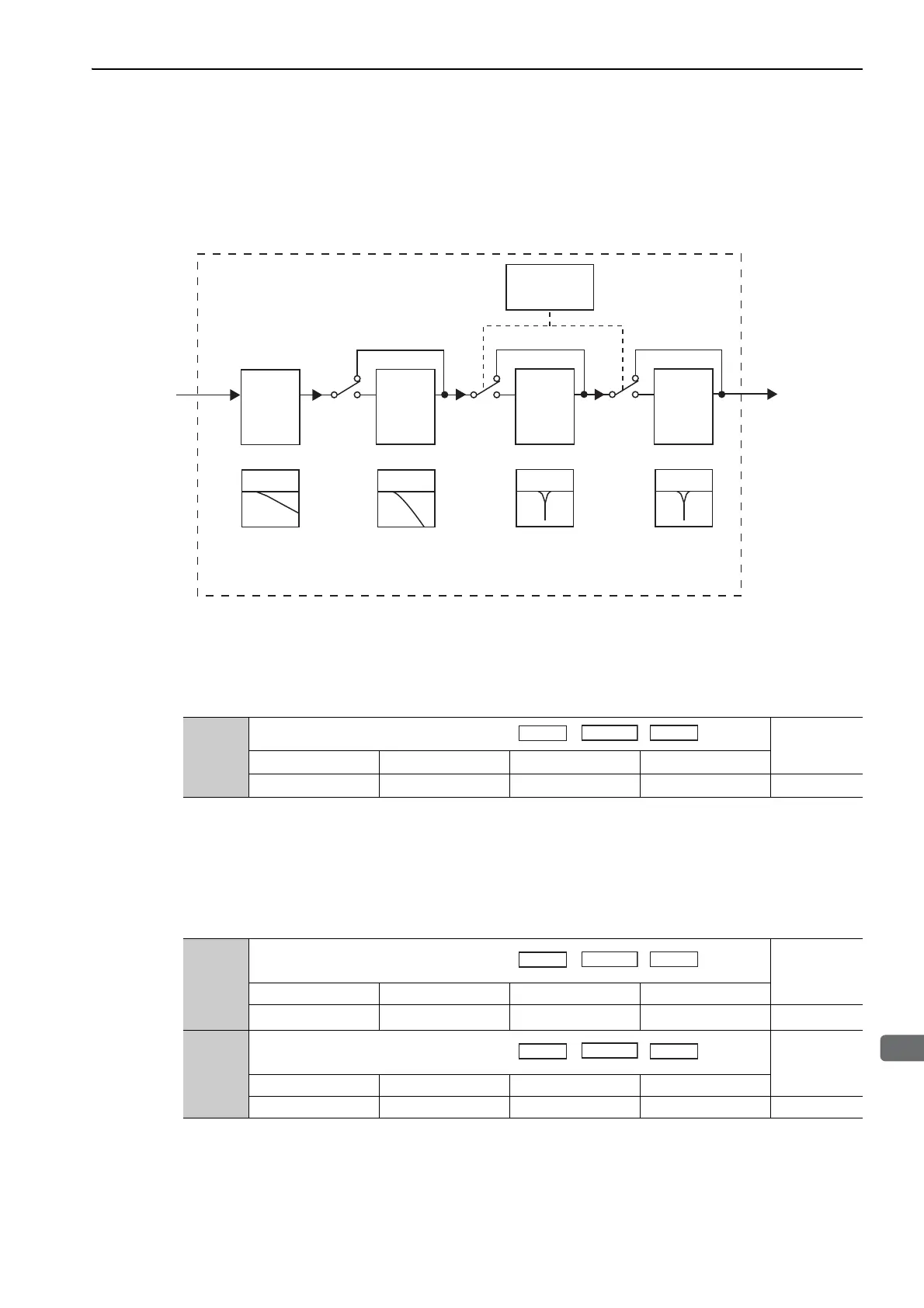

Pn401

Torque Reference Filter Time Constant

Classification

Setting Range Setting Unit Factory Setting When Enabled

0 to 65535 0.01 ms 100 Immediately Tuning

Torque

Pn40F

2nd Step 2nd Torque Reference Filter

Frequency

Classification

Setting Range Setting Unit Factory Setting When Enabled

100 to 5000 1 Hz

5000

*

Immediately Tuning

Pn410

2nd Step 2nd

Torque

Reference Filter

Q Value

Classification

Setting Range Setting Unit Factory Setting When Enabled

50 to 100 0.01 50 Immediately Tuning

Torque

Torque

Loading...

Loading...