1 Outline

1.4.3 Speed/Position/Torque Control

1-12

∗1. Set Pn001 to 2 in the multi-winding drive unit parameters if you will not use the dynamic brake.

∗2. Implement risk assessment and confirm that the safety requirements of the machine have been met.

1.4.3 Speed/Position/Torque Control

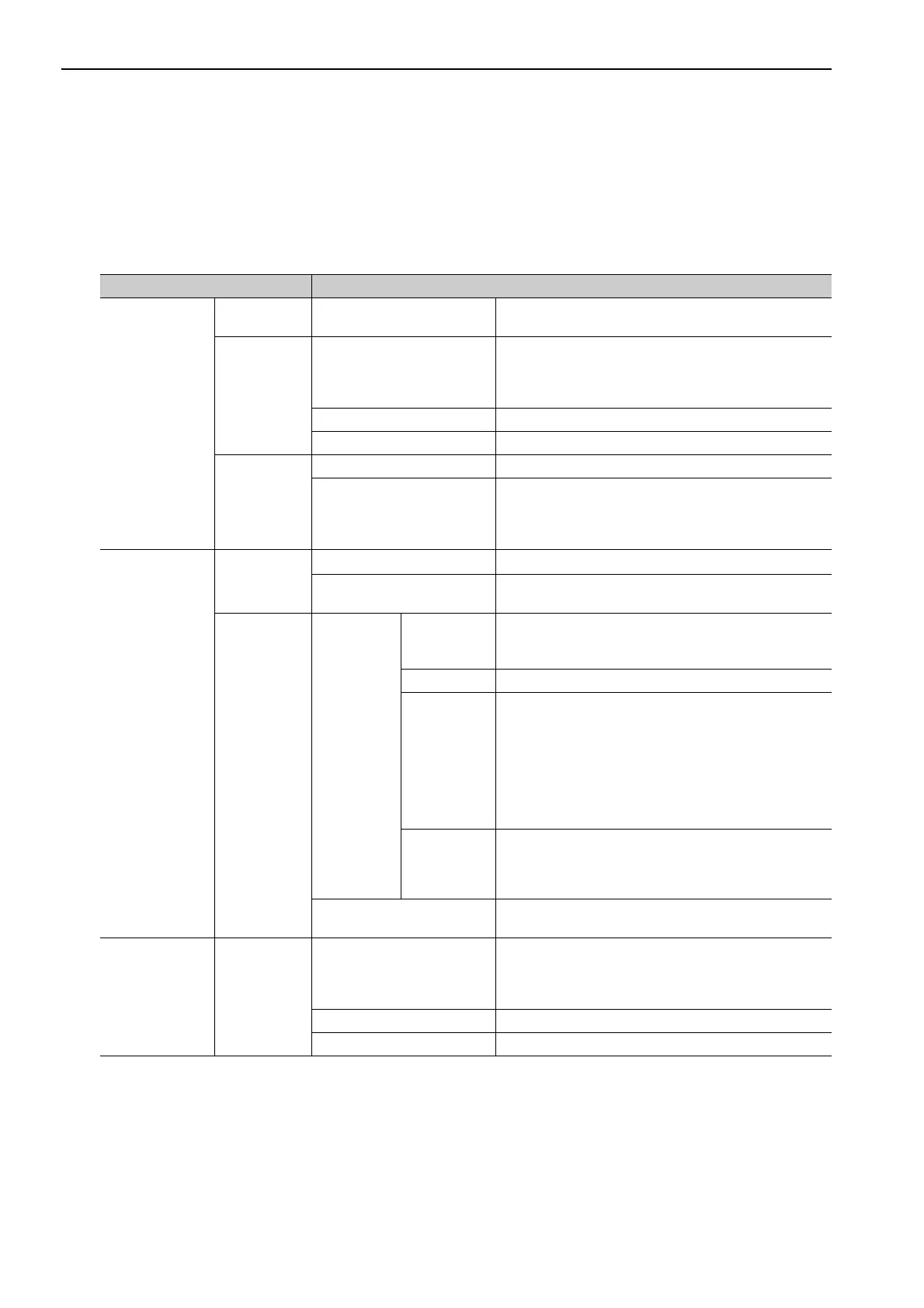

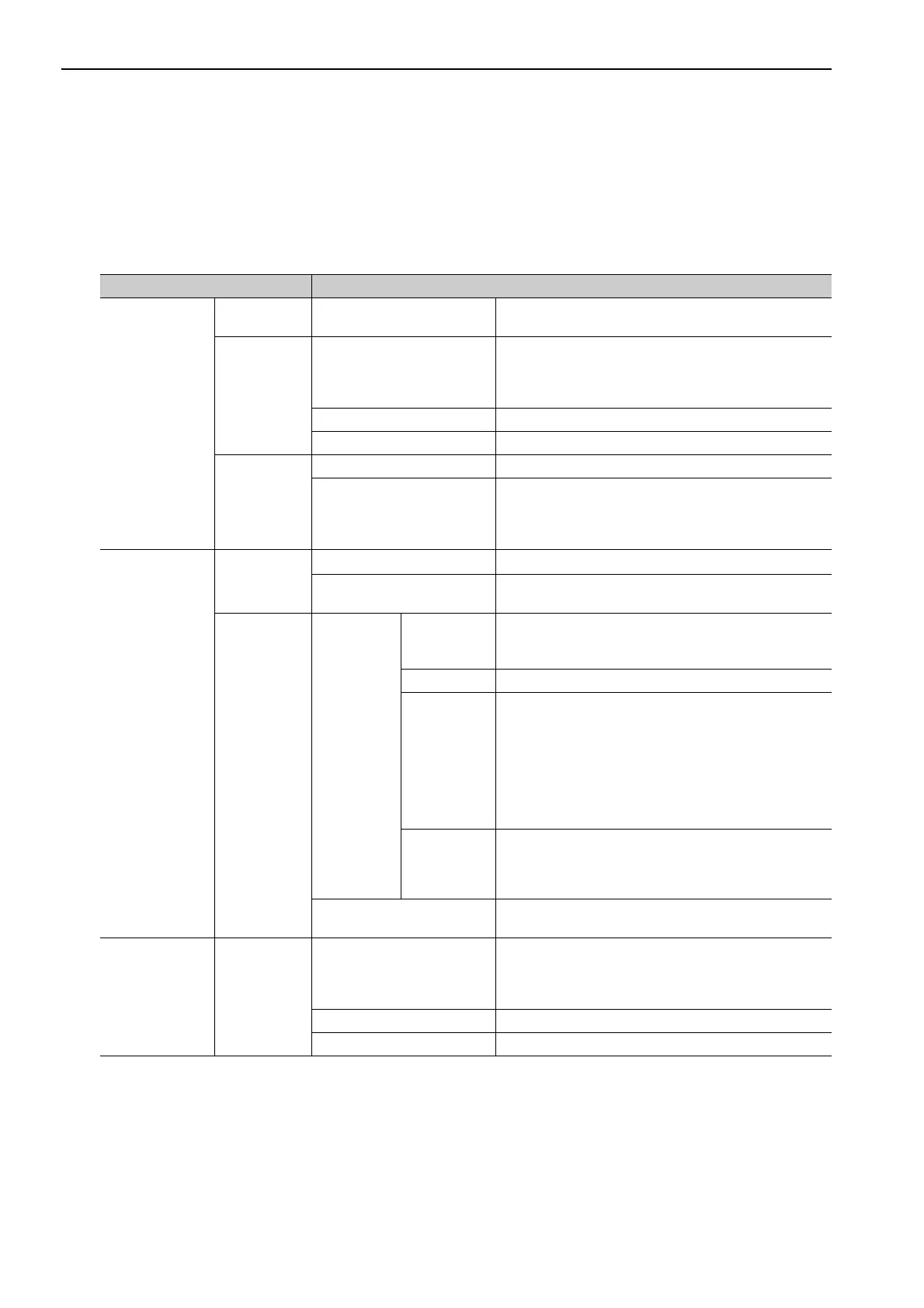

The following table shows the basic specifications of the multi-winding drive unit at speed/position/torque

control.

Control Method Specifications

Speed Control

Performance Soft Start Time Setting

0 to 10 s (Can be set individually for acceleration and

deceleration.)

Input Signals

Reference Voltage

• Max. input voltage: ±12 V

(forward speed reference with positive reference)

• Factory setting: 6 VDC at rated speed

Input gain setting can be varied.

Input Impedance Approx. 14 kΩ

Circuit Time Constant 30 μs

Internal Set

Speed Control

Rotation Direction Selection With P control signal

Speed Selection

With forward/reverse external torque limit signal (speed 1

to 3 selection).

Servomotor stops or another control method is used when

both are OFF.

Position Control

Performance

Feedforward Compensation

0% to 100%

Positioning Completed

Width Setting

0 to 1073741824 reference units

Input Signals

Reference

Pulse

Type

Select one of them:

Sign + pulse train, CW + CCW pulse train, or two-phase

pulse train with 90° phase differential

Form For line driver, open collector

Max. Input

Pulse Fre-

quency

Line driver

Sign + pulse train, CW + CCW pulse train: 4 Mpps

Two-phase pulse train with 90° phase differential:

1 Mpps

Open Collector

Sign + pulse train, CW + CCW pulse train: 200 kpps

Two-phase pulse train with 90° phase differential:

200 kpps

Reference

Pulse Input

Multiplication

Switching

1 to 100 times

Clear Signal

Position error clear

For line driver, open collector

Torque Control Input Signals

Reference Voltage

• Max. input voltage: ±12 V

(forward torque reference with positive reference)

• Factory setting: 3 VDC at rated torque

Input gain setting can be varied.

Input Impedance Approx. 14 kΩ

Circuit Time Constant 16 μs

Loading...

Loading...