6 Adjustments

6.7.2 Torque Feedforward

6-46

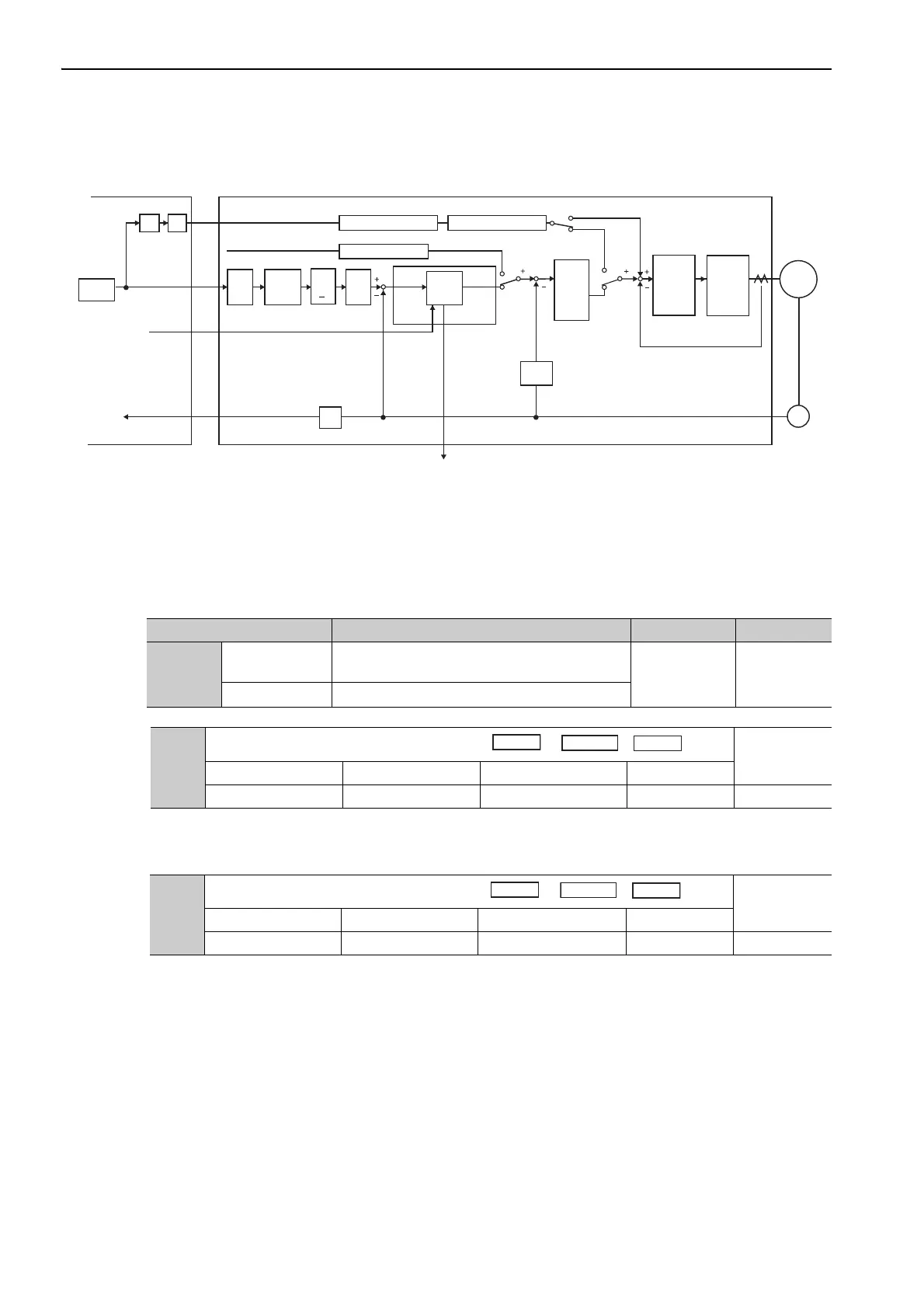

When the Multi-winding Drive Unit Performs Position Control

(2) Related Parameters

Torque feedforward is set using the parameters Pn002, Pn400, and Pn415.

The factory setting is Pn400 = 3.0 V/rated torque.

For example, the torque feedforward value is

±3 V, then, the torque is limited to ±100% of the rated torque.

Note 1. Too high a torque feedforward value will result in overshooting. To prevent such troubles, set the optimum value

while observing the system responsiveness.

2. The torque feedforward function cannot be used with torque limiting by analog voltage reference.

COIN

M

Pn200.0 Pn218 Pn20E

Pn210

Pn400

T-REF

V-REF

CLR

PULS, SIGN

K

FF

Pn300

Pn415

Pn212

Pn216

Pn217

Pn002.0

ENC

Pn000.1 Pn000.1

Multi-winding drive system

Divider

K

FF

: Feedforward gain

Clear input

Speed reference input gain

T-REF filter time constant

Position

reference

Differe-

ntial

Host controller

Servomotor

Torque reference input gain

Refer-

ence

pulse

form

Smooth-

ing

Position

feedback

Error

counter

Pn522 positioning

completed width

Speed

conver-

sion

Speed

control

section

Current

control

section

Power

amplifier

Current feedback

Speed feedback

Position control

section

Encoder

output pulse

Elec-

tronic

gear

B

A

Reference

Pulse

Multiplier

× n

Parameter Meaning When Enabled Classification

Pn002

n.

0

[Fac-

tory setting]

Disabled

After restart Setup

n.

2

Uses T-REF terminal for torque feedforward input.

Pn400

Torque Reference Input Gain

Classification

Setting Range Setting Unit Factory Setting When Enabled

10 to 100 0.1 V/rated torque 30 Immediately Setup

Pn415

T-REF Filter Time Constant

Classification

Setting Range Setting Unit Factory Setting When Enabled

0 to 65535 0.01 ms 0 Immediately Setup

Position

Torque

Loading...

Loading...