5.1 Example Setting of Motion Parameters for the Machine

5.1.2 Electronic Gear

5-3

Motion Parameter Setting Examples

The following setting example uses ball screw and rotating table workpieces.

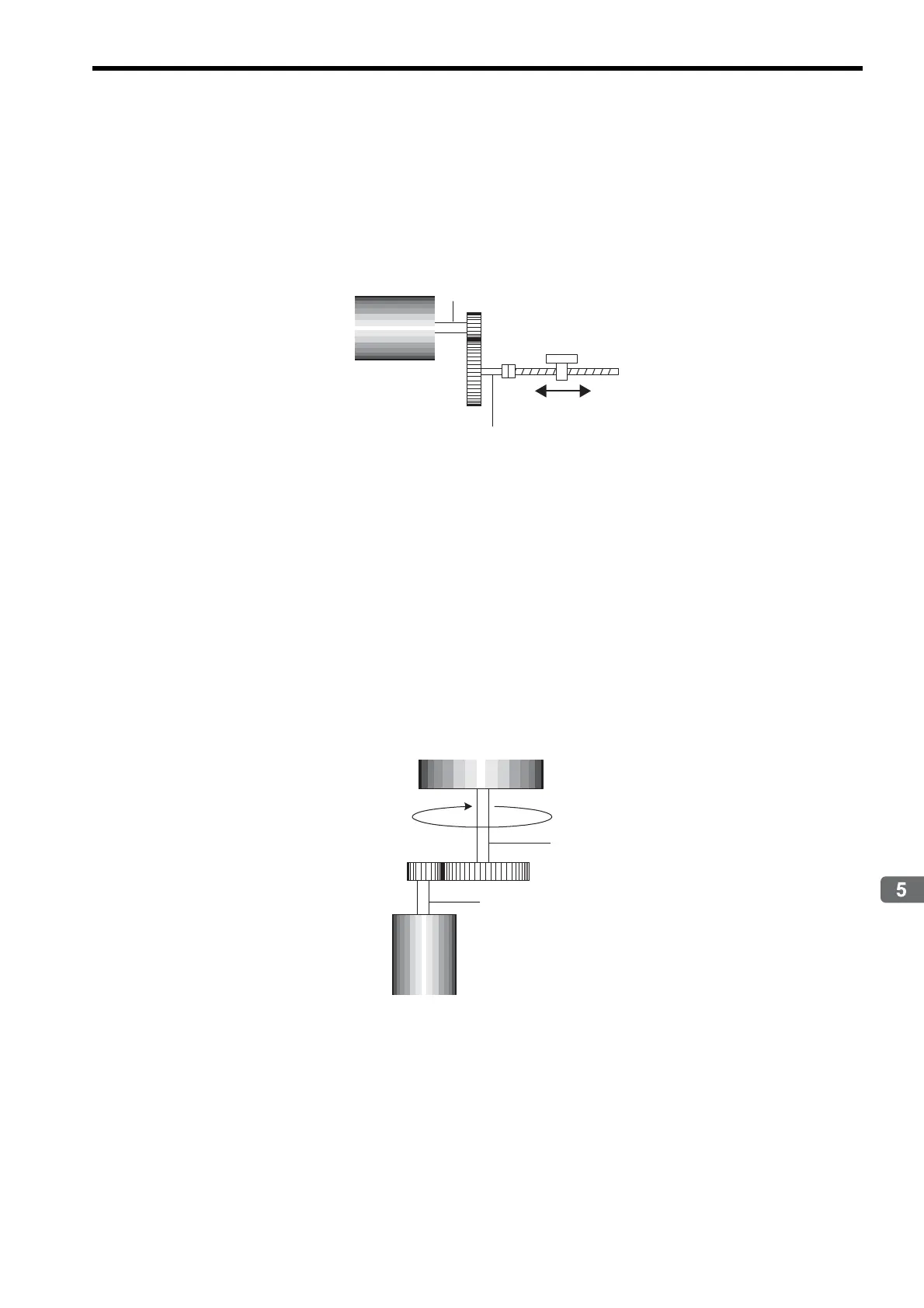

( 1 ) Parameter Setting Example Using Ball Screw

• Machine specifications: Ball screw axis rotates 5 times for each 7 rotations of the motor axis (Refer to the follow-

ing figure.)

• Reference unit: 0.001 mm

To move the workpiece 0.001 mm for 1 reference unit input under the conditions outlined above, i.e., for 1 reference

unit = 1 output unit, make the following settings for fixed parameters 6, 8, and 9.

• Fixed Parameter 6: Travel Distance per Machine Rotation = 6 mm/0.001 mm = 6000 (reference units)

• Fixed Parameter 8: Servo Motor Gear Ratio = m = 7

• Fixed Parameter 9: Machine Gear Ratio = n = 5

Set the SERVOPACK gear ratio to 1:1. However, if you are using a Σ-7-series SERVOPACK, refer to 11.8 Pre-

cautions When Using

Σ

-7-series SGD7S SERVOPACKs with Rotary Servomotors and set the SERVOPACK’s

electronic gear.

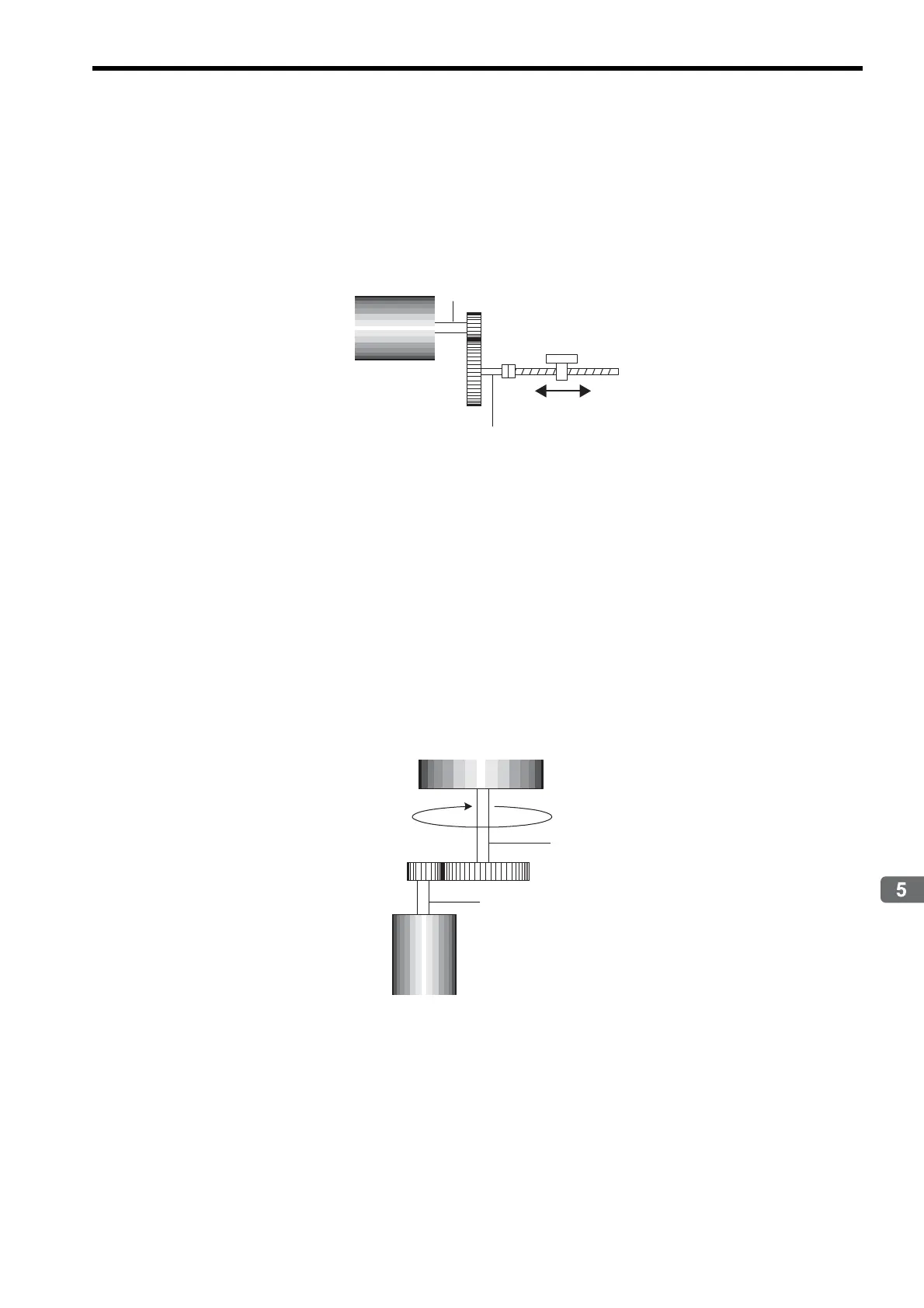

( 2 ) Parameter Setting Example Using Rotating Table

• Machine specifications: Rotating table axis rotates 10 times for each 30 rotations of the motor axis (Refer to the

following figure.)

• Reference unit: 0.1°

To rotate the table 0.1° for 1 reference unit input under the conditions outlined above, i.e., for 1 reference unit = 1 out-

put unit, make the following settings for fixed parameters 6, 8, and 9.

• Fixed Parameter 6: Travel Distance per Machine Rotation = 360°/0.1° = 3600 (reference units)

• Fixed Parameter 8: Servo Motor Gear Ratio = m = 30

• Fixed Parameter 9: Machine Gear Ratio = n = 10

The gear ratio for fixed parameters 8 and 9 (m/n) may be constant, e.g., m = 3 and n = 1.

Set the SERVOPACK gear ratio to 1:1. However, if you are using a Σ-7-series SERVOPACK, refer to 11.8 Pre-

cautions When Using

Σ

-7-series SGD7S SERVOPACKs with Rotary Servomotors and set the SERVOPACK’s

electronic gear.

Ball screw

Workpiece

P (pitch) = 6 mm/rotation

m = 7 rotations

n = 5 rotations

Motor

Workpiece (Rotating table)

360°/rotation

n = 10 rotations

Motor

m = 30 rotations

Loading...

Loading...