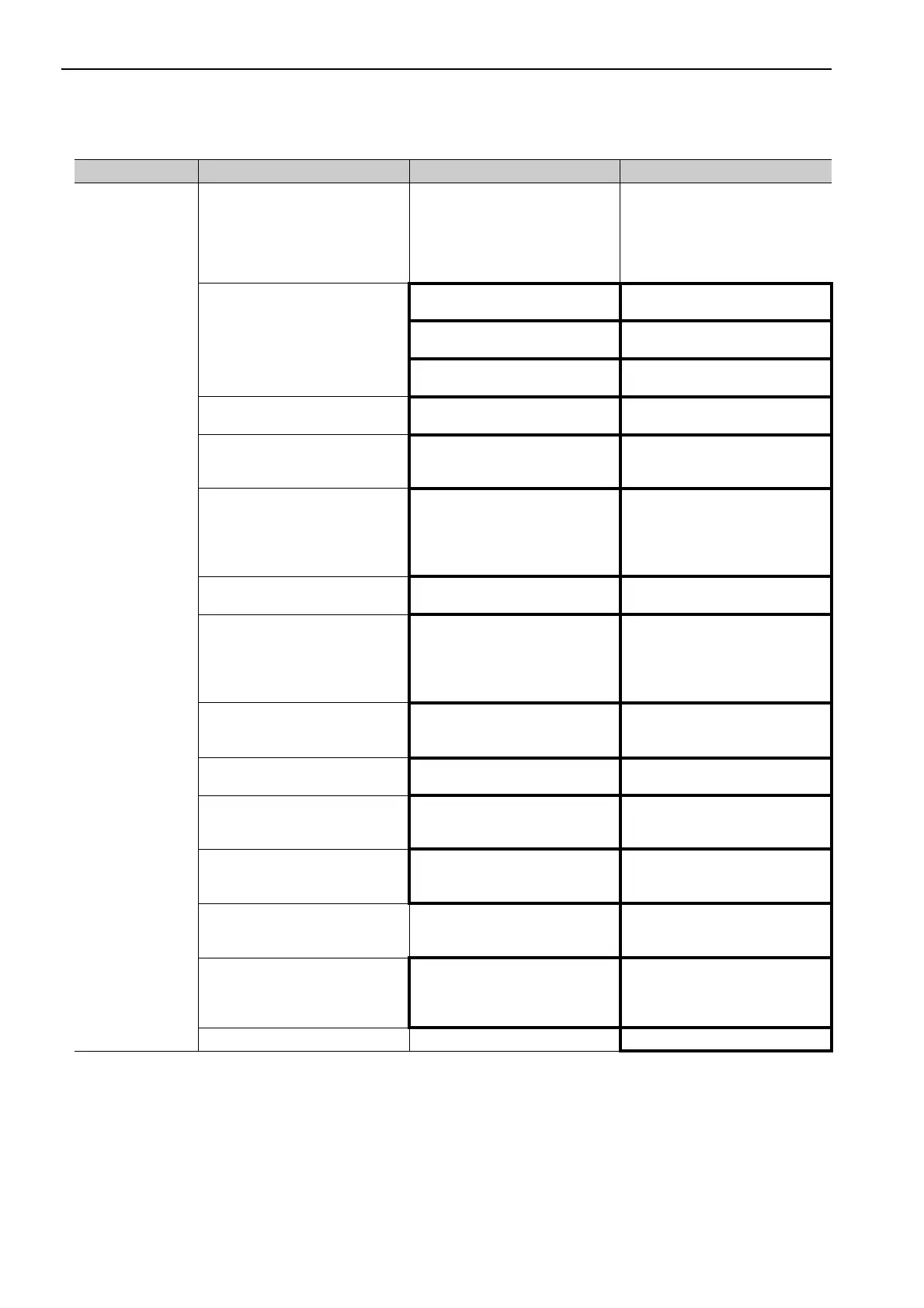

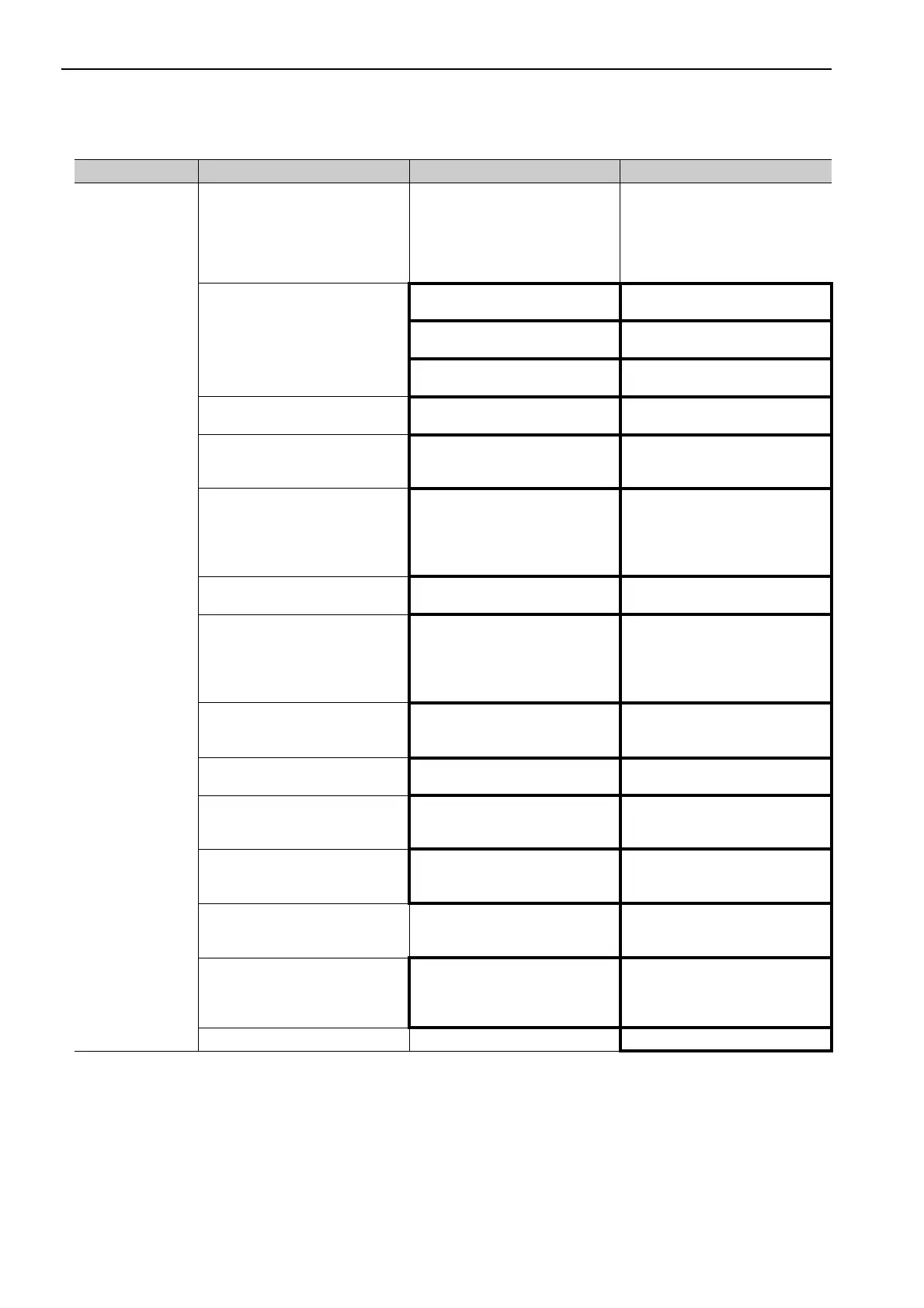

9 Troubleshooting

9-30

Abnormal Noise

from Servomotor

The servomotor largely vibrated

during execution of tuning-less

function.

Check the motor speed waveform.

Reduce the load so that the moment

of inertia ratio becomes within the

allowable value, or increase the

load level or lower the tuning level

for the tuning-less levels setting

(Fn200).

Mounting is not secured.

Check if there are any loose mount-

ing screws.

Tighten the mounting screws.

Check if there is misalignment of

couplings.

Align the couplings.

Check if there are unbalanced cou-

plings.

Balance the couplings.

Bearings are defective.

Check for noise and vibration

around the bearings.

Replace the servomotor.

Vibration source at the driven

machine.

Check for any foreign matter, dam-

age, or deformations on the machin-

ery's movable parts.

Contact the machine manufacturer.

Noise interference due to incorrect

I/O signal cable specifications.

The I/O signal cable must be tinned

annealed copper shielded twisted-

pair or screened unshielded twisted-

pair cable with a core of 0.12 mm

2

min.

Use the specified I/O signal cable.

Noise interference due to length of

I/O signal cable.

Check the length of the I/O signal

cable.

Make the I/O signal cable length

less than 3 m.

Noise interference due to incorrect

cable specifications of encoder

cable.

The encoder cable must be tinned

annealed copper shielded twisted-

pair or screened unshielded twisted-

pair cable with a core of 0.12 mm

2

min.

Use the specified encoder cable.

Noise interference due to length of

encoder cable.

Check the length of the encoder

cable.

The encoder cable must be no more

than 50 m.

Noise interference due to damaged

encoder cable.

Check if the encoder cable is bent

and the sheath is damaged.

Replace the encoder cable and cor-

rect the cable layout.

Excessive noise to the encoder

cable.

Check if the encoder cable is bun-

dled with a high-current line or near

a high-current line.

Correct the cable layout so that no

surge is applied.

The FG potential varies because of

influence from machines on the ser-

vomotor side, such as the welder.

Check if the machines are correctly

grounded.

Properly ground the machines to

separate from the encoder FG.

SERVOPACK pulse counting error

due to noise interference

Check if there is noise interference

on the I/O signal line from the

encoder.

Take measures against noise in the

encoder wiring.

Excessive vibration and shock to

the encoder

Check if vibration from the machine

occurred or servomotor installation

is incorrect (mounting surface accu-

racy, fixing, alignment, etc.).

Reduce vibration from the machine,

or secure the servomotor installa-

tion.

An encoder fault occurred. − Replace the servomotor.

(cont’d)

Problem Probable Cause Investigative Actions Corrective Actions

Loading...

Loading...