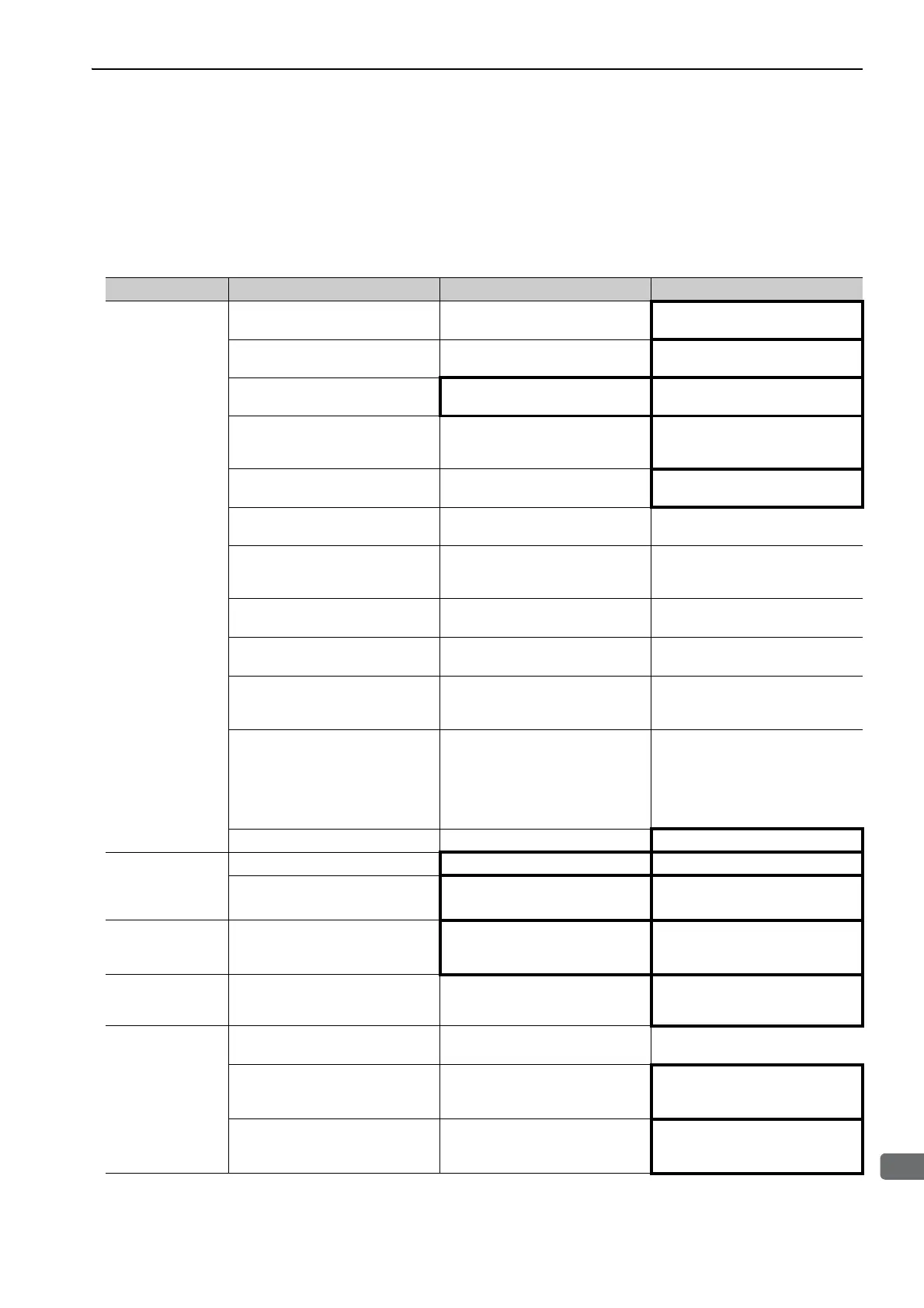

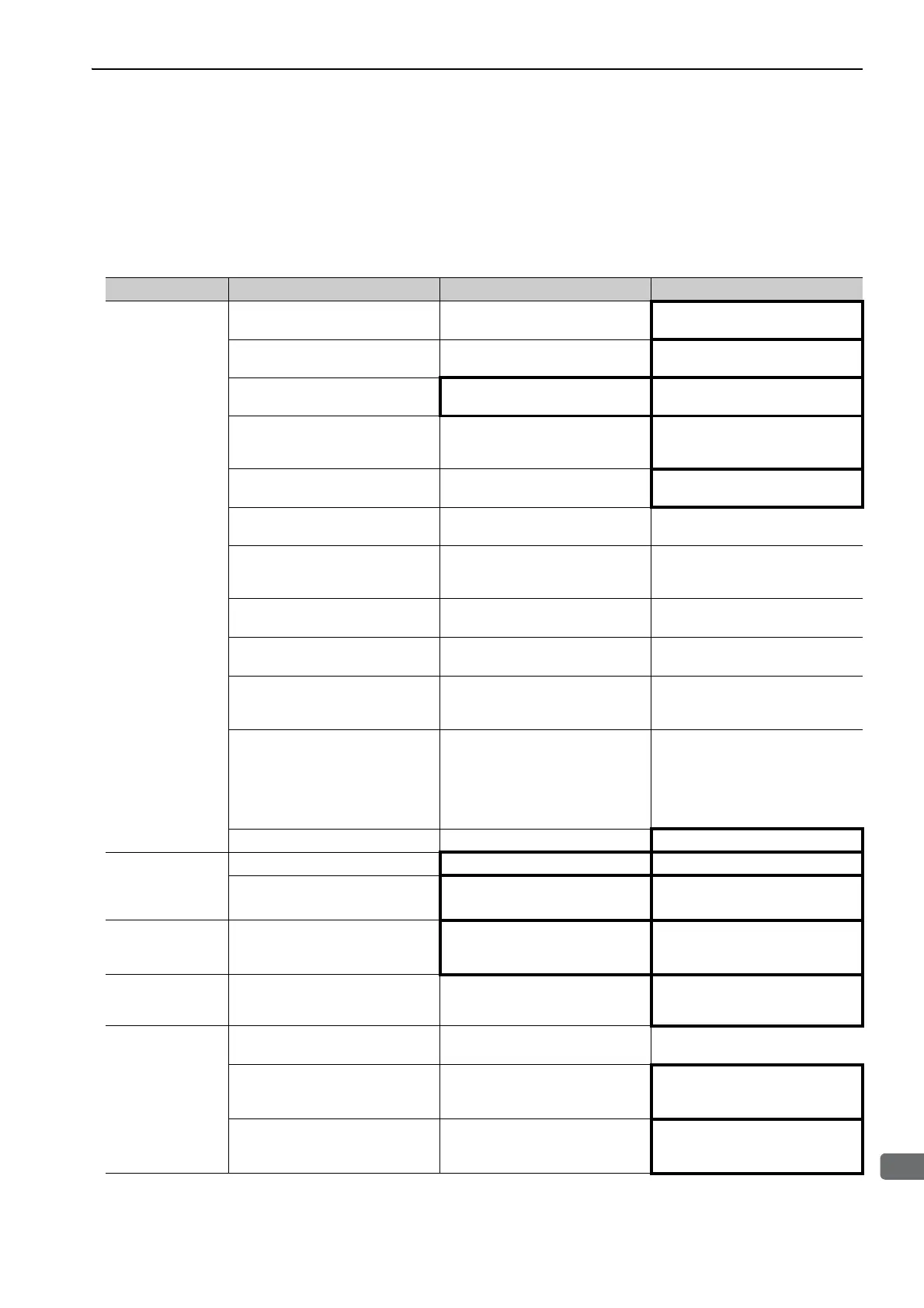

9.4 Troubleshooting Malfunction Based on Operation and Conditions of the Servomotor

9-29

9.4 Troubleshooting Malfunction Based on Operation and

Conditions of the Servomotor

Troubleshooting for the malfunctions based on the operation and conditions of the servomotor is provided in

this section.

Be sure to turn OFF the servo system before troubleshooting items shown in bold lines in the table.

Problem Probable Cause Investigative Actions Corrective Actions

Servomotor Does

Not Start

The control power supply is not

ON.

Check voltage between control

power terminals.

Correct the wiring.

The main circuit power supply is

not ON.

Check the voltage between main

circuit power terminals.

Correct the wiring so that the main

circuit power supply turns ON.

Wiring of I/O signal connector CN1

is faulty or disconnected.

Check if the connector CN1 is prop-

erly inserted and connected.

Correct the connector CN1 connec-

tion.

Wiring for servomotor main circuit

cable or encoder cable is discon-

nected.

Check the wiring. Correct the wiring.

Overloaded

Run under no load and check the

load status.

Reduce load or replace with larger

capacity servomotor.

Encoder type differs from parame-

ter setting (Pn002.2).

Check the settings for parameter

Pn002.2.

Set parameter Pn002.2 to the

encoder type being used.

Settings for the input signal selec-

tions (Pn50A, Pn50B and Pn511) is

incorrect.

Check the settings for parameters

Pn50A, Pn50B and Pn511.

Correct the settings for parameter

Pn50A, Pn50B and Pn511.

SV_ON command is not sent.

Check the command sent from the

host controller.

Send the SV_ON command.

SENS_ON command is not sent.

Check the command sent from the

host controller.

Send the command in the correct

SERVOPACK sequence.

The forward run prohibited (P-OT)

and reverse run prohibited (N-OT)

input signals are turned OFF.

Check P-OT or N-OT input signal.

Turn P-OT or N-OT input signal

ON.

The safety input signal

(/HWBB1 or /HWBB2) remains

OFF.

Check the /HWBB1 and /HWBB2

input signal.

Set the /HWBB1 and /HWBB2

input signal to ON.

When not using the safety function,

mount the safety function’s jumper

connector (provided as an acces-

sory) on the CN8.

A SERVOPACK fault occurred. − Replace the SERVOPACK.

Servomotor

Moves

Instanta-

neously,

and then

Stops

Servomotor wiring is incorrect. Check the wiring. Correct the wiring.

Encoder wiring is incorrect. Check the wiring. Correct the wiring.

Servomotor

Speed Unstable

Wiring connection to servomotor is

defective.

Check connections of power line

(phases U, V, and W) and encoder

connectors.

Tighten any loose terminals or con-

nectors and correct the wiring.

Servomotor Ro-

tates Without Ref-

erence Input

A SERVOPACK fault occurred. − Replace the SERVOPACK.

Dynamic Brake

Does Not Operate

Improper Pn001.0 setting

Check the setting for parameter

Pn001.0.

Correct the setting for parameter

Pn001.0.

DB resistor disconnected

Check if excessive moment of iner-

tia, motor overspeed, or DB fre-

quently activated occurred.

Replace the SERVOPACK, and

reduce the load.

DB drive circuit fault −

There is a defective component in

the DB circuit. Replace the SER-

VOPACK.

Loading...

Loading...