3 Wiring and Connection

3.6.1 Encoder Signal (CN2) Names and Functions

3-28

3.6 Encoder Connection

This section describes the encoder signal (CN2) names, functions, and connection examples.

3.6.1 Encoder Signal (CN2) Names and Functions

The following table shows the names and functions of encoder signals (CN2).

∗ These do not need to be connected for an incremental encoder.

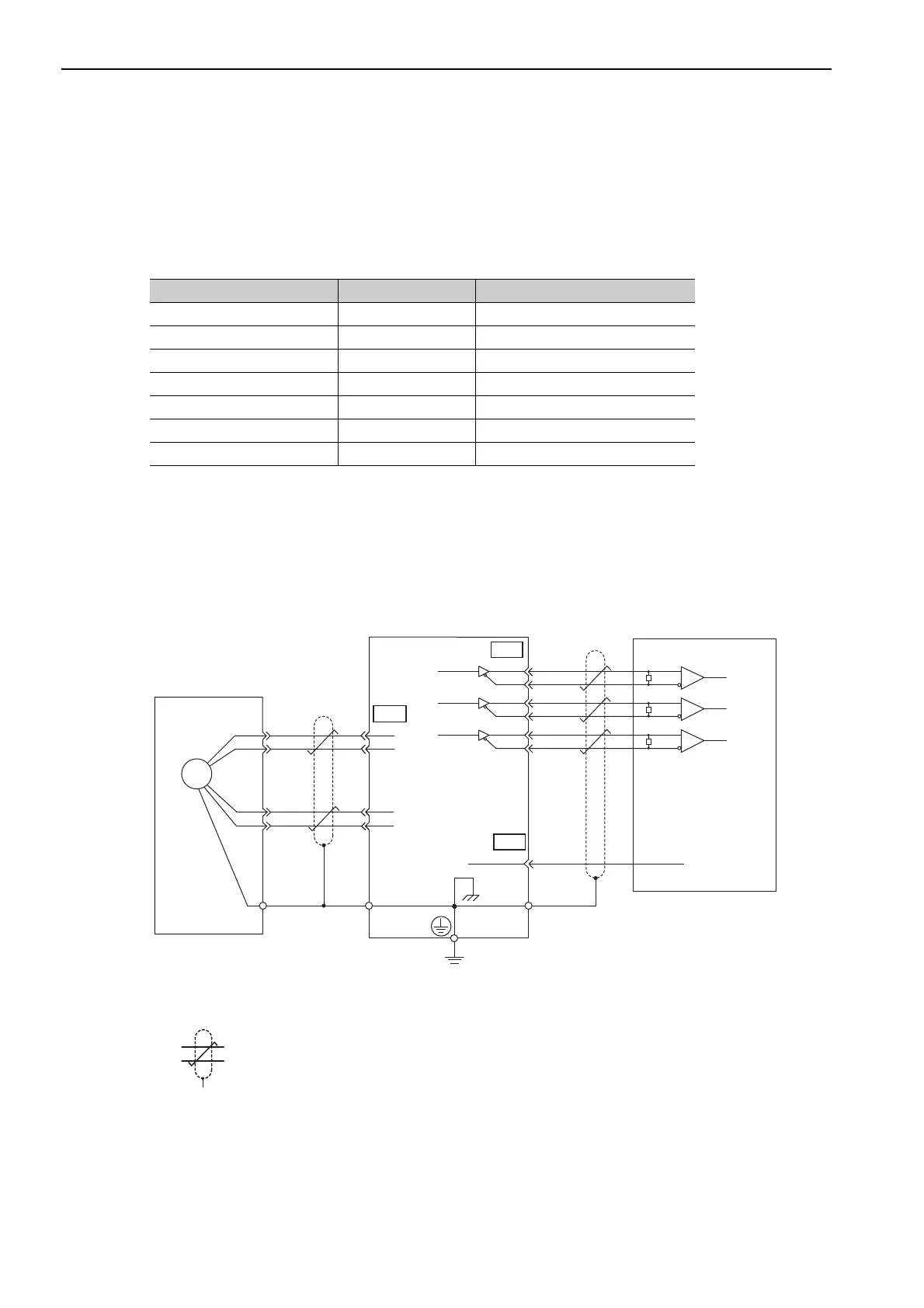

3.6.2 Encoder Connection Examples

The following diagrams show connection examples of the encoder, the SERVOPACK, and the host controller.

(1) Incremental Encoder

∗1. The pin arrangement for wiring connectors varies in accordance with the servomotor that is used.

∗2. : represents shielded twisted-pair wires.

Signal Name Pin No. Function

PG5V 1 Encoder power supply +5 V

PG0V 2 Encoder power supply 0 V

BAT (+)* 3 Battery (+)

BAT (-)* 4 Battery (-)

PS 5 Serial data (+)

/PS 6 Serial data (-)

Shield Shell –

19

0 V

SG

16

PA

O

/P AO

PBO

/PBO

PCO

/PCO

1

2

5

6

CN2

17

18

20

21

22

ENC

CN1

CN1

PS

/PS

PG5 V

PG0 V

0 V

R

R

R

Incremental encoder

Shielded wire

(Shell)

Connector shell

Connector

shell

Output line-driver SN75ALS174

manufactured by Texas

Instruments or the equivalent

Phase A

Phase A

Phase B

Phase B

Phase C

Phase C

SERVOPACK

Host controller

∗1

∗2

∗2

R (terminating resistance): 220 to 470 Ω

Applicable line receiver:

SN75ALS175 or MC3486

manufactured by Texas

Instruments,

or the equivalent

Loading...

Loading...