113D SYSTEMS, INC.

PERSONAL PROTECTIVE EQUIPMENT

Gloves

Wear disposable nitrile gloves when handling powders. Dispose of the gloves when the powder handling operation is

complete. Do not operate switches or use door handles or other xtures while still wearing the gloves in order to prevent cross

contamination.

Clothing

When working in areas where reactive metal condensates are present, use re-retardant special fabric, rendered conductive,

trousers without turn-ups, closed pockets.

Safety Masks

Wear disposable dust mask that is rated N99 (FFP3) or equivalent level protection.

Safety Goggles

Wear close tting safety goggles or a full face mask when handling powder. In case of emergency, use an eye shower to

remove any particles from the eye(s).

Safety Shoes

The use of safety shoes is mandatory in any area where heavy items are handled. This includes powder vessels, building

plates and the build module. In any area where powder is handled, safety shoes with antistatic soles are required.

Hygiene

It is advised to wash your hands, even when wearing gloves, after handling powder. It is also recommended to shower and wash your

hair after removing the protective clothing at the end of a day’s work.

A

HAND TOOLS

You must acquire non-sparking, non-magnetic hand tools that are safe for Ex zones

where hazardous, ammable or combustible vapors, liquids, dusts or residues may be

present. Hand tools such as trowels, screwdrivers, dustpans, should be composed of:

• Aluminum

• Aluminum-Bronze (AlBr)

• Copper-Beryllium (CuBe2) alloys

You must also acquire and use natural ber or ESD safe brushes and brooms. Work

benches must be grounded.

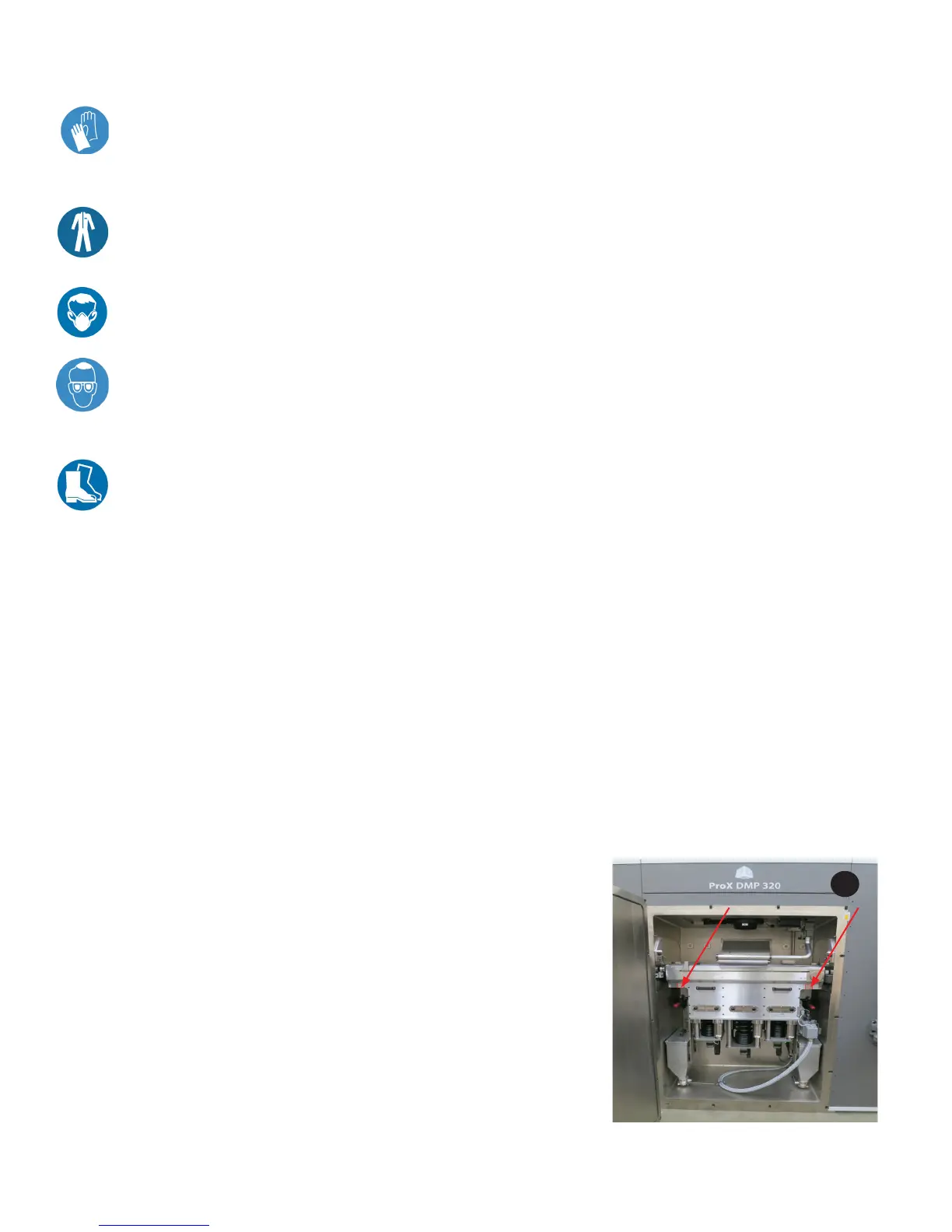

GROUNDING

Grounding personnel and equipment when working with powder is highly

recommended. The DMP building chamber is grounded as a safety feature. When no

other option is available, personnel can be grounded to this chamber using an antistatic

bracelet. Similarly, all auxiliary equipment (including explosion proof), can be grounded

by attaching the provided grounding leads to the DMP chamber (A). However to ensure

easy, uncomplicated operation, the following is recommended:

• Dedicated grounding points in each process room

• Antistatic ooring or Antistatic oor mats

In addition it is recommended to check the grounding itself on a regular basis in

accordance to local regulations.

Loading...

Loading...