513D SYSTEMS, INC.

Preparing ProX DMP 320

Always use appropriate safety equipment when operating the ProX

DMP320. The feeds can be adjusted in DMP Deposition.

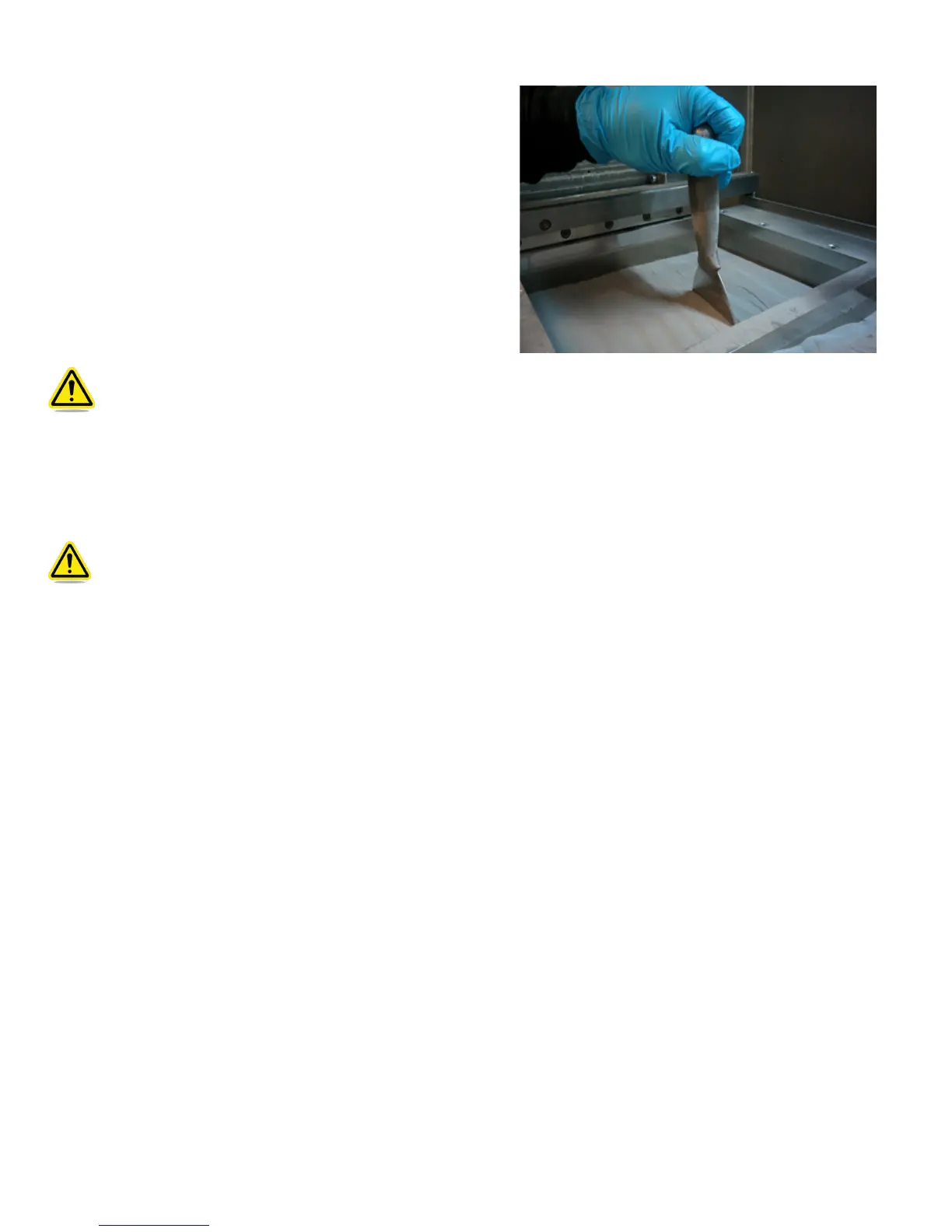

Fill the feeds with the material. Add about 100mm of powder then

thrust a stainless steel trowel in the powder a few times to compact

the powder. Continue with adding and compacting until the needed

amount is added to the feeds. Make sure that the feeds are equally

lled and there is enough material to complete the job. Multiply the

job height by 1.25 to get the amount of material needed to have a

successful build. Example: If the job height is 100mm then each feed

has to have 125mm of material installed.

Because the feed have to move down while inerting you can only ll

up the feed bins for 320mm. If more powder is needed for a build, ll

the build shute with 140mm of extra powder and, after inerting, move

this powder to the feed bins with the coater.

WARNING: Any time powder material is handled (i.e.,

relling, sifting, changing, etc.) make sure you are

either standing on an anti-static mat, or you are wearing

a grounding strap that is attached to the module so that

you are grounded to the machine. Always pour or scoop

slowly from as close to surface as possible to avoid

producing dust from material. It is also advised that the

vacuum dust extractor be over top of the bin.

CAUTION: The print plate must be compatible with the print material.

Loading...

Loading...