453D SYSTEMS, INC.

This list helps you check that all preparation steps have been fullled before starting the print.

Fill out the checklist and press on the continue button to start inerting the printer. After this the printer will be ready to print. The actual

printing command will be given from within DMP control. This checklist will be stored in the Deposition.log le.

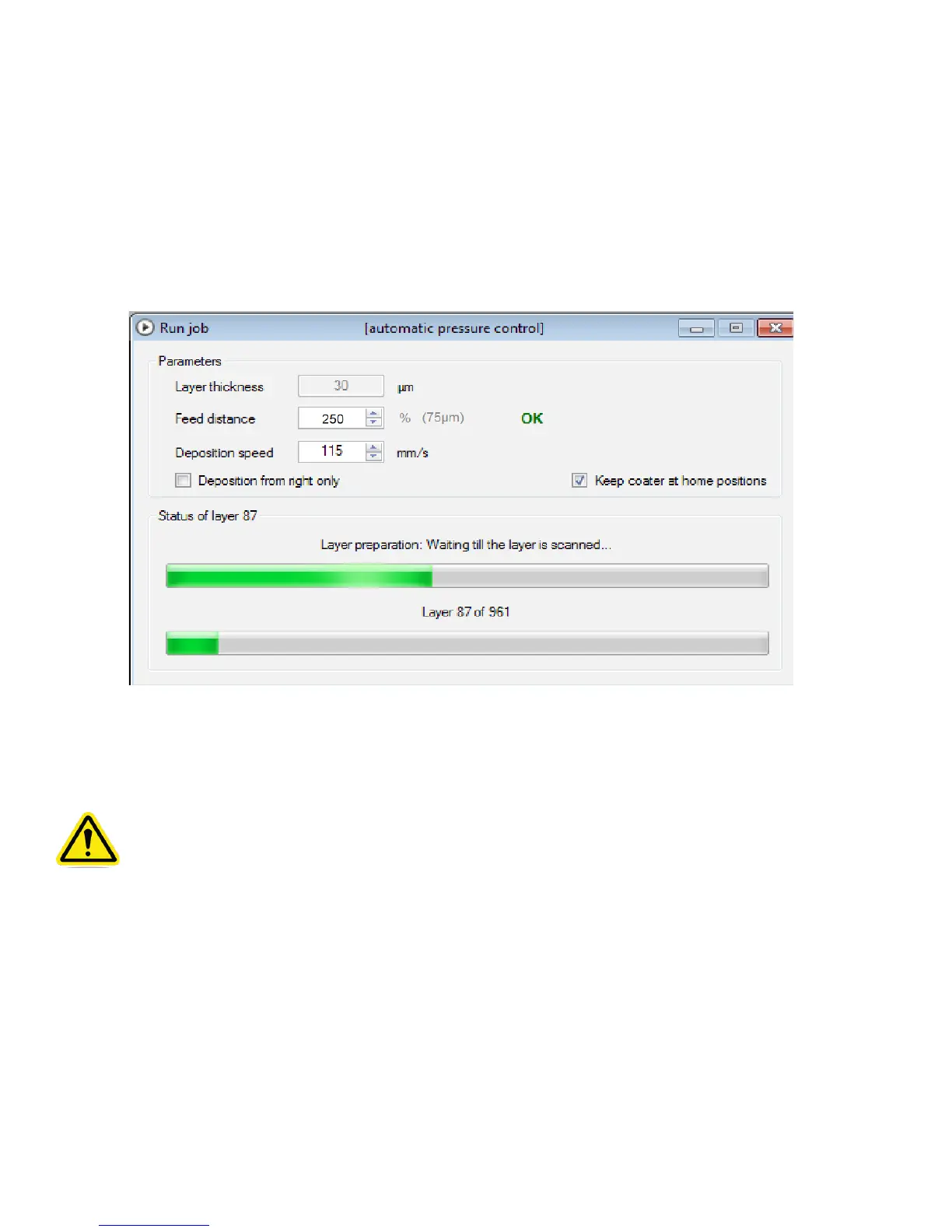

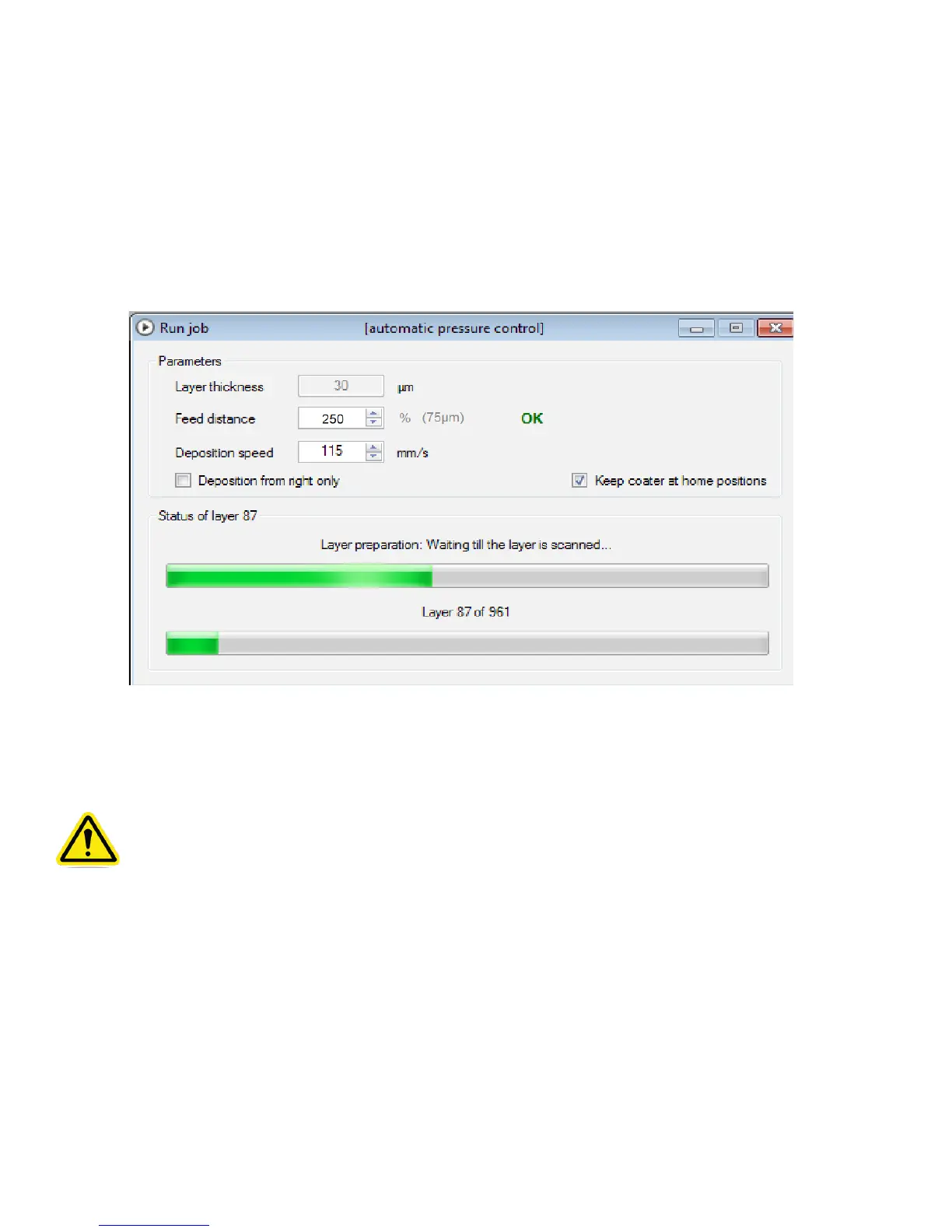

Run job

This gives the current status of print job (what action is being performed and what is the current layer).

It allows you to change some parameters. This windows opens after the machine has gone through the preparation cycle. This screen

must be active if you want to start a job. If DMP deposition is closed for some reason after the preparation cycle, the program will

automatically ask whether you have inerted the machine. If you inerted the machine correctly, press yes. To start a job now, open the

run job screen manually.

• Feed distance: How much the feed platforms will go up each time to provide the coater with enough powder. (in percent of layer

thickness), making this number higher will reduce short feed occurrences but will use up more powder.

• Deposition speed: How fast the coater will move while depositing new powder on the build bed.

CAUTION: changing this parameter can change part properties (mechanical properties, surface roughness, etc.)

•

• Deposition from the right only: Used if you have a limited supply of powder and only want to ll one of the two feeds. Only powder

from the right feed will be deposited on the building platform this will increase the overall deposition time of the job.

• Keep coater at home positions: With this option set the coater will go to its endposition and wait there after each powder deposition.

When this option is not set, the coater will go the end position after deposition and then go back to between the building platform

and the feed to wait for the next deposition cycle.

Loading...

Loading...