413D SYSTEMS, INC.

DMP Deposition

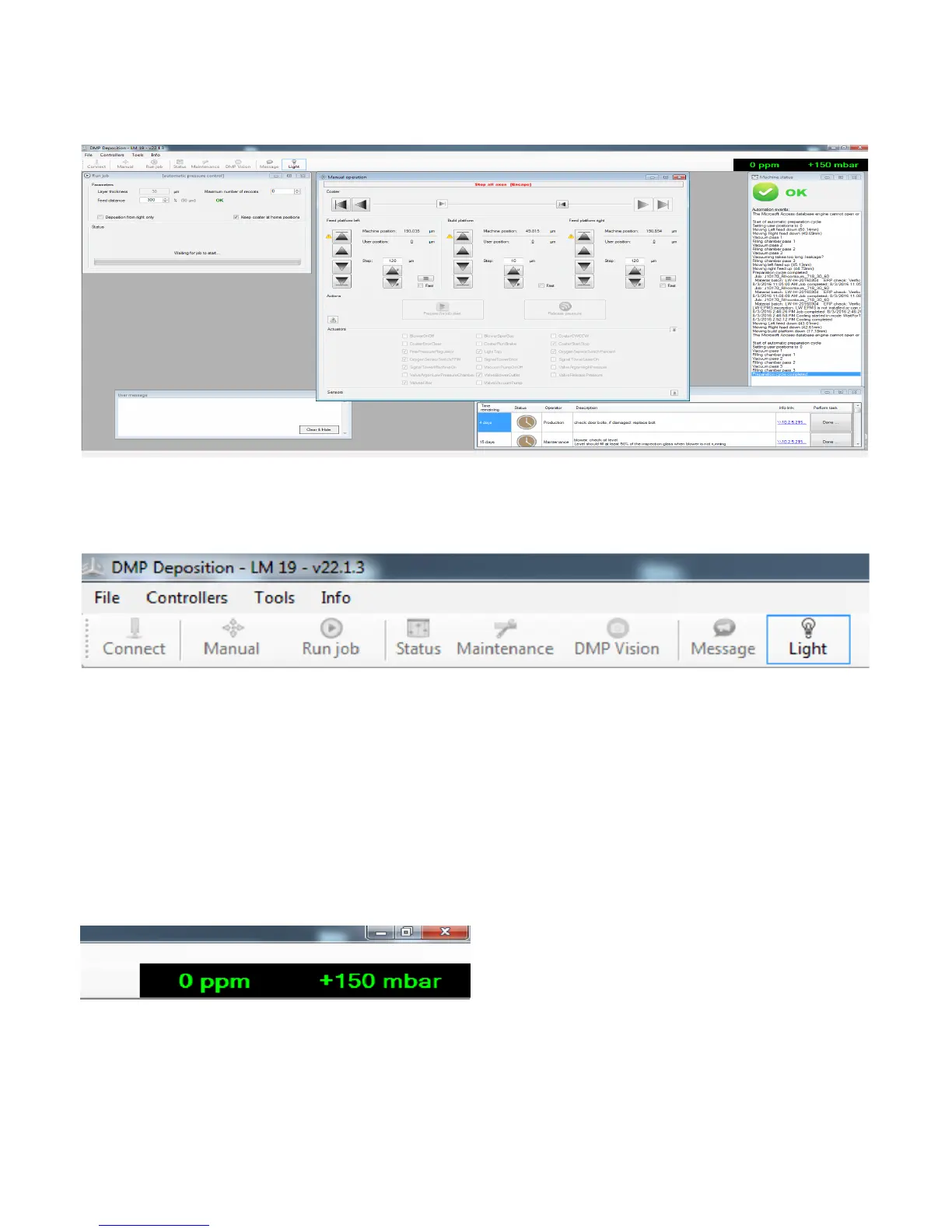

DMP deposition is used for preparing the printer before a print job, checking sensors/actuators and doing maintenance. While printing,

this program controls all movements, sensors and vacuum cycle.

DMP Deposition is build up out of the following parts:

The Menu Bar

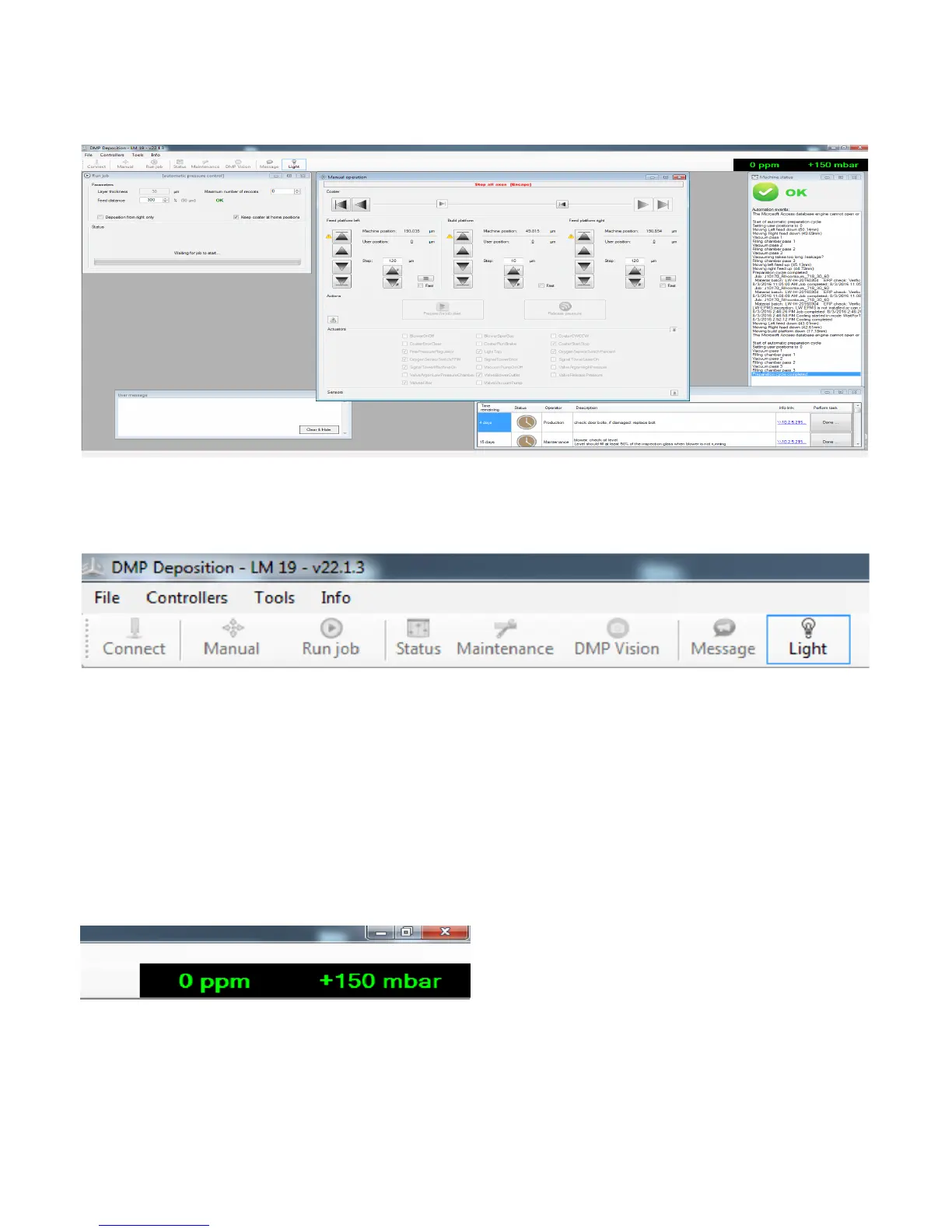

From here all different sub-modules can be accessed

• Connect – Connect to the machine

• Manual – manually control the machine and perform actions

• Run Job – Window that will be shown during printing

• Status – Opens up the Machine status screen

• Maintenance – Opens up the Maintenance tasks module

• DMP Vision – Separately purchasable module that visually checks the coaterbed

• Message – Opens up the User Message screen

• Light – Turns on/off the process chamber light

• On the right side of the menu bar the current oxygen level in the process chamber is shown. The displayed unit will be in % while

the chamber is at high oxygen content and will switch to ppm (parts per million) when the oxygen content gets lower. This will be

shown as soon as the printer starts preparing to print. Next to that is the relative pressure in the process chamber (in millibar). A

negative number means there is underpressure, a positive number overpressure

Loading...

Loading...