-EN Rev. E Operating instruction SCK Gas Sampling System 113

Installation check

Risk of injury in the area of the gas sampling system due to moving or fall-

ing parts, hot surfaces, anti-freeze, compressed air, lubricating oil

Wear general personal protective equipment:

Closed overalls with long trousers and long sleeves

Safety shoes

Safety gloves suitable for mechanical work

Safety glasses

Protective helmet

If necessary, additional protective equipment if prescribed by the opera-

tor.

Check the installation for correct condition before start-up. The following

section describes this procedure. If one of these requirements is not met,

abort start-up and do not continue until the appropriate conditions have been

created.

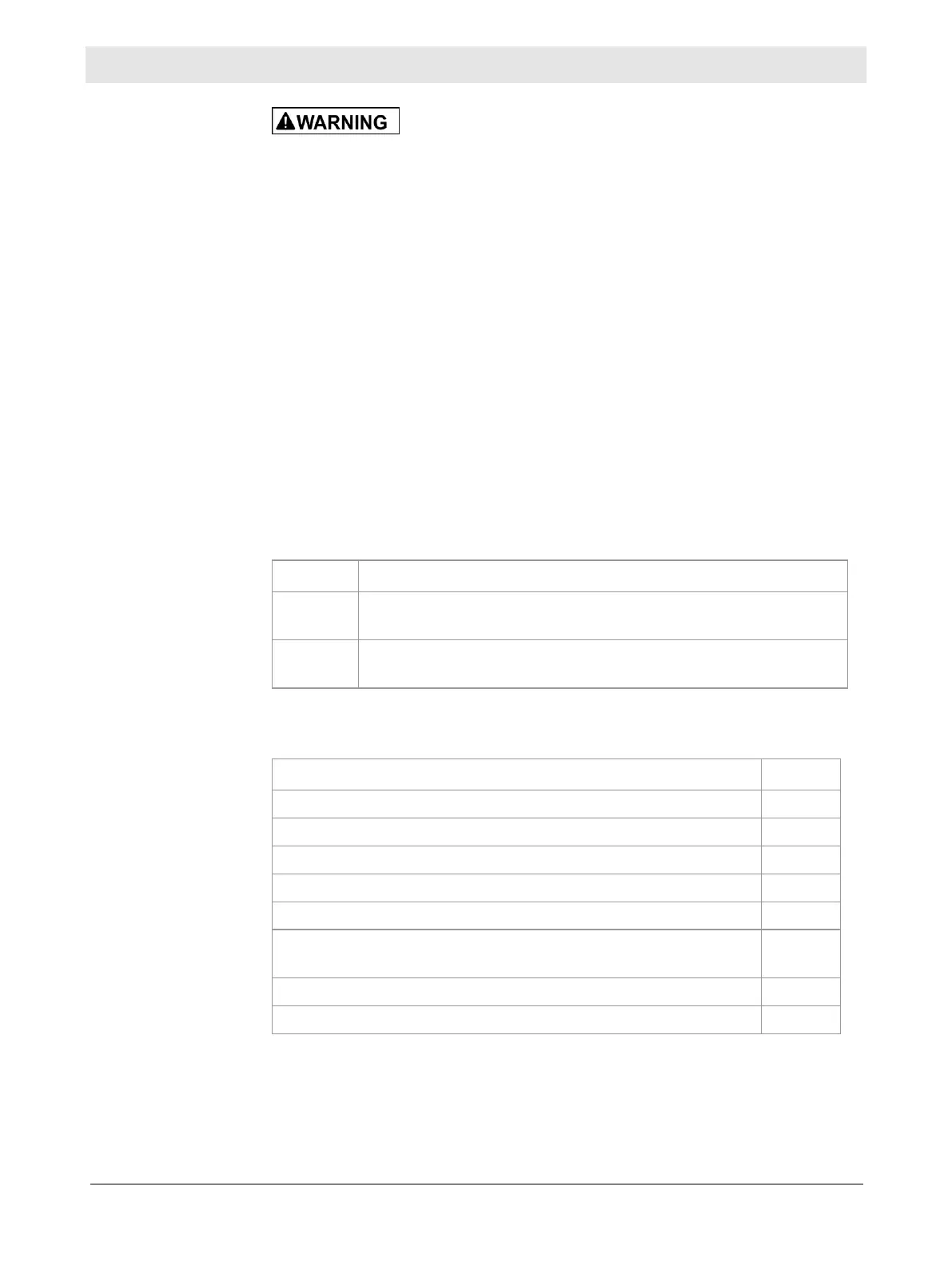

How to check the installation:

Step Procedure

1

Based on the checklist below, check whether the gas sampling

system was installed correctly.

2

Only continue to start up the gas sampling system once all

conditions have been met.

The following conditions must be met:

Conditions OK

No visible damage to the modules.

Connection and laying of electric lines checked.

Connection and laying of pneumatic lines checked.

Connection and laying of cooling-water lines checked.

Heat exchanger connected with a shielded cable.

Adherence to the bending radii of the installed lines and hoses

checked.

Stable fastening of the modules checked.

Protective probe box fitted.

Mechanical, thermal

and material dangers

Loading...

Loading...