216 Operating instruction SCK Gas Sampling System OI/SCK-EN Rev. E

Errors and irregularities

If an error occurs, the system triggers automatic processes to protect the gas

sampling probe:

Phase Description

1

The sampling system is switched to manual mode.

2

The gas sampling probe is retracted out of the kiln.

WARNING! Probe movement. Do not stand in the area of travel

of the probe or probe carriage.

Result: Because the gas sampling probe is in manual mode, the

gas sampling probe can no longer move in on its own.

Note: In the event of danger to personnel, you can interrupt these automatic

processes by pressing the EMERGENCY-STOP switch.

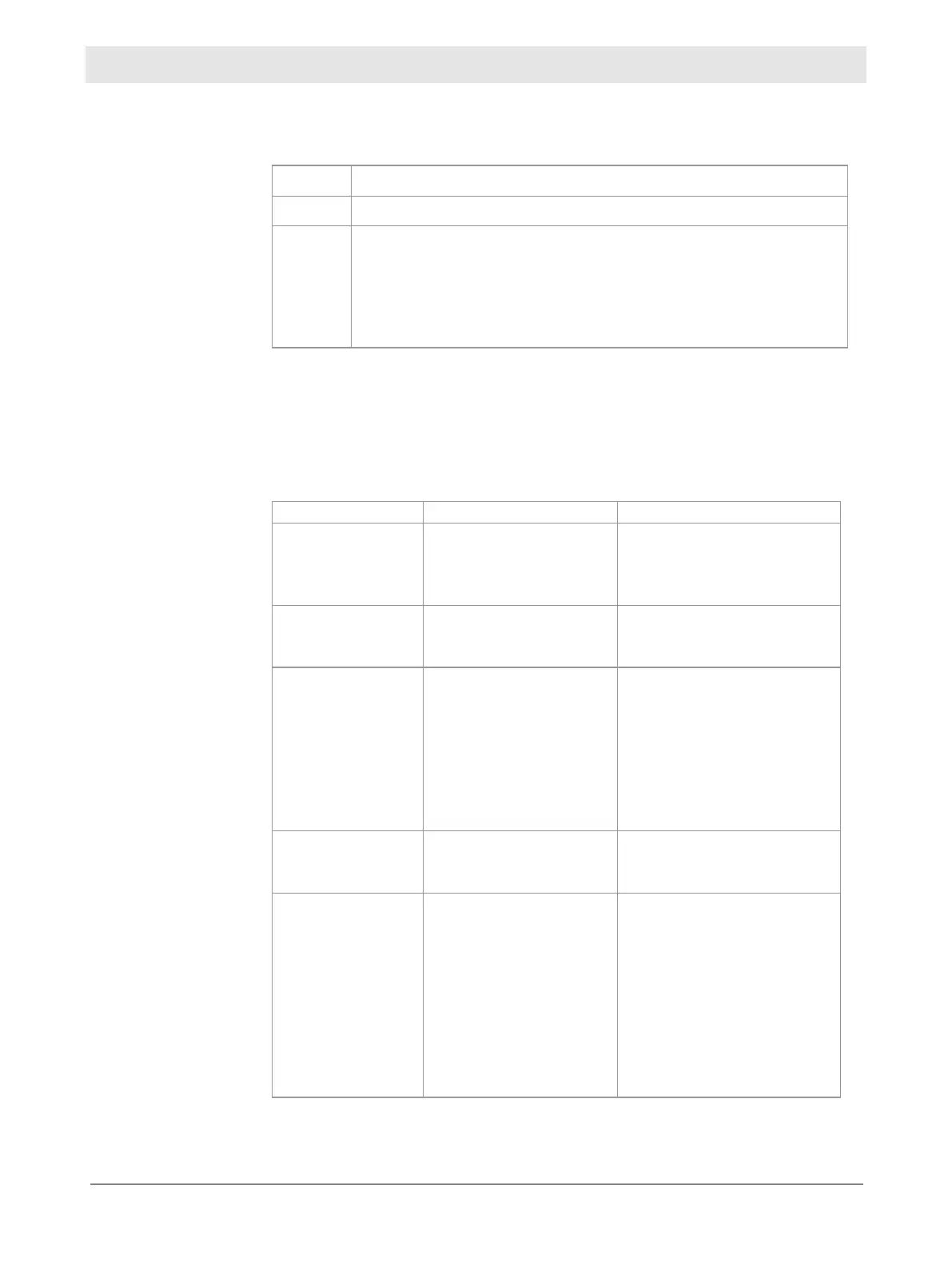

The following table describes irregularities that may occur during operation

of the gas sampling system and measures to be taken to remedy them:

noise

defective

Compressed-air

motor defective

nance department or

ABB Service

Whistling noise

from compressed-

Compressed-air

system leak

See

Checking for leaks

on page 173

Probe travel is

jerky

Probe carriage rails

dirty

Wrong inclination of

probe carriage

Clean rails

Readjust probe carriage

inclination using the ad-

justment screws, see

Probe retractor: Check-

ing and, if necessary, ad-

justing the position of

tered in kiln aper-

align-

Untypical or gur-

gling noises in the

cooling-water

circuit

Air bubbles in the

cooling-water circuit

Vent cooling-water cir-

cuit, see

Venting the cooling-

water circuit

on page

208

Top up cooling water,

see

Cooling module:

cooling water

on page

Automatic processes

corrective action

Loading...

Loading...