-EN Rev. E Operating instruction SCK Gas Sampling System 115

Proceed as follows (note: it is advisable for two people to perform this work):

Connect the filling pipe to the cooling-water supply of the

cooling module.

Note: Make sure that there are no dirt deposits in the filling

pipe; rinse first.

Note: The cooling water is tinted due to formation of metal

oxides in the heat exchanger. The functional capability is not

affected.

Note: Cooling water filling pressure > 1 bar (1000 hPa).

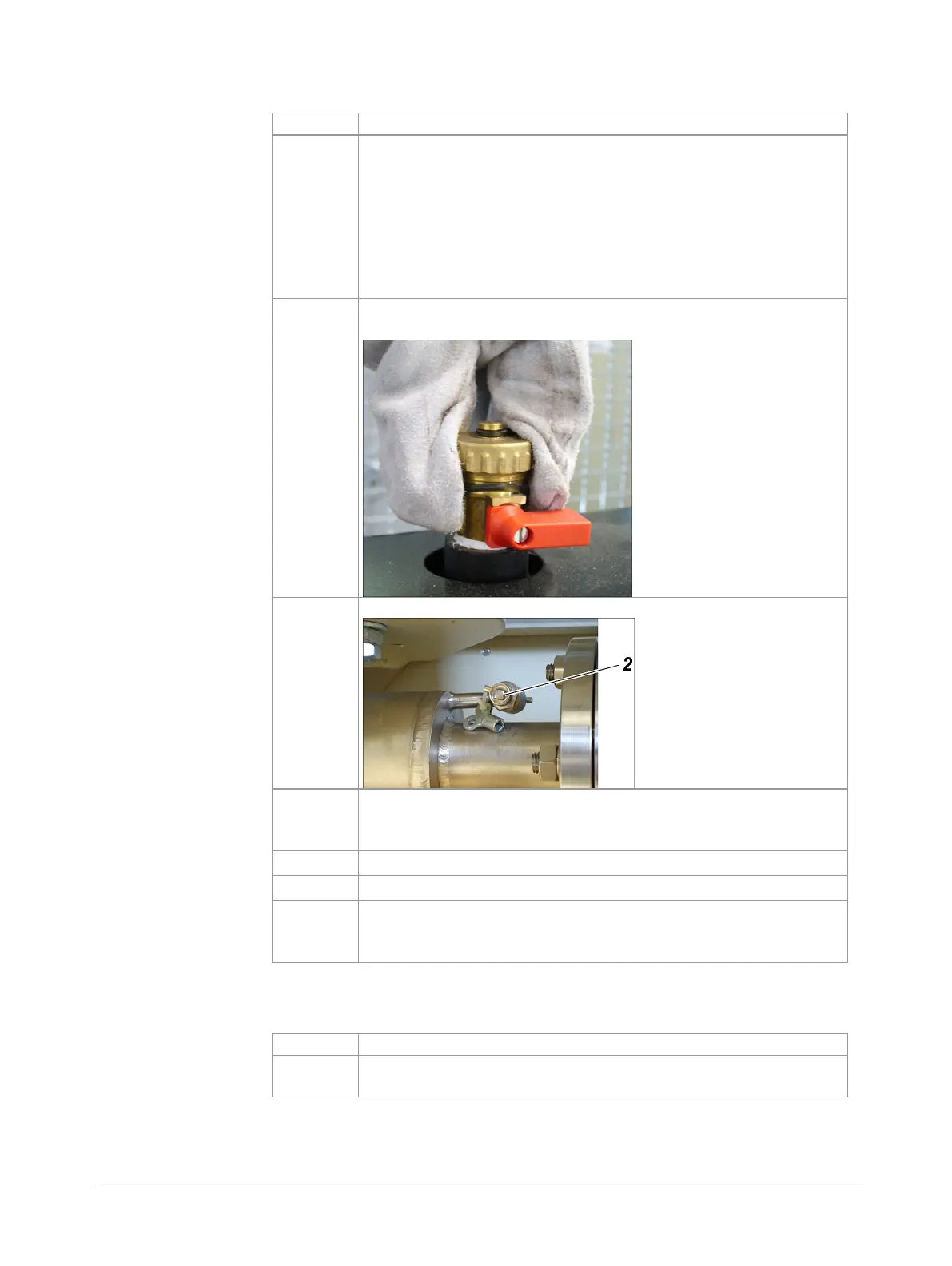

On the top of the heat exchanger: Unscrew cap on drain valve

and open vent cock (red).

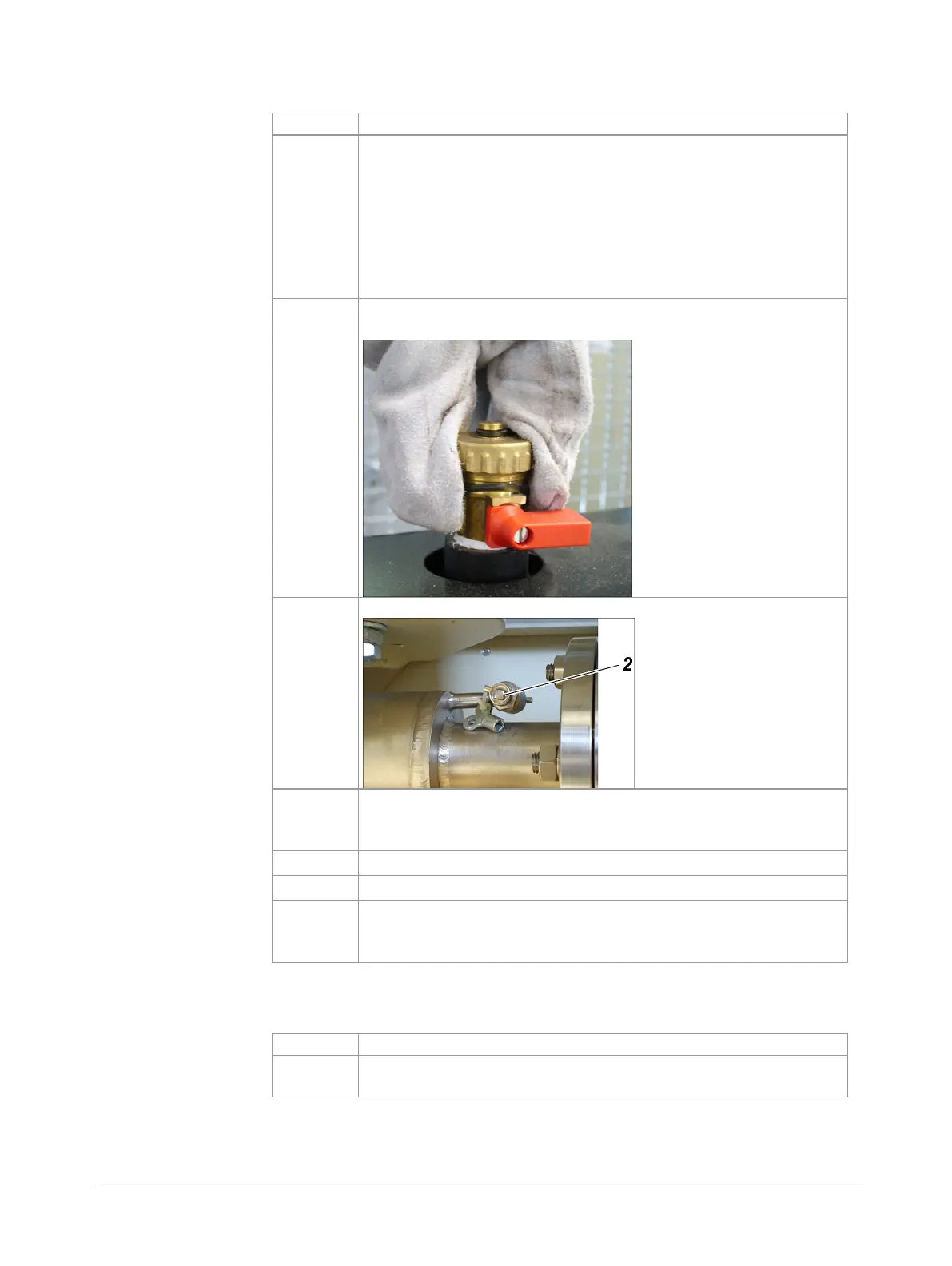

Open drain valves

(2)

on gas sampling probe.

Slowly open the shut-off valve -J63 on the cooling module and

allow cooling water to flow in until

cooling water appears at the

drain valves of the heat exchanger and gas sampling probe.

Close shut-off valve -J63.

Close drain valves on heat exchanger and gas sampling probe.

Check pressure of cooling water in the controller and top up if

necessary (target cooling water pressure in cooled state: 1-1.5

Proceed as follows:

Check cooling water circuit for leaks. Remedy any leaks before

continuing with start-up.

up cooling water

for leaks

Loading...

Loading...