-EN Rev. E Operating instruction SCK Gas Sampling System 175

How to check the cooling-water circuit for leaks:

Switch service switch to

ON

position (see

Operating the

service switch

on page 161), press EMERGENCY STOP

switch and allow gas sampling system to cool down.

WARNING!

Risk of burning in the event of contact with

components that are still hot.

Do not touch components

until they have cooled down to below 50 °C.

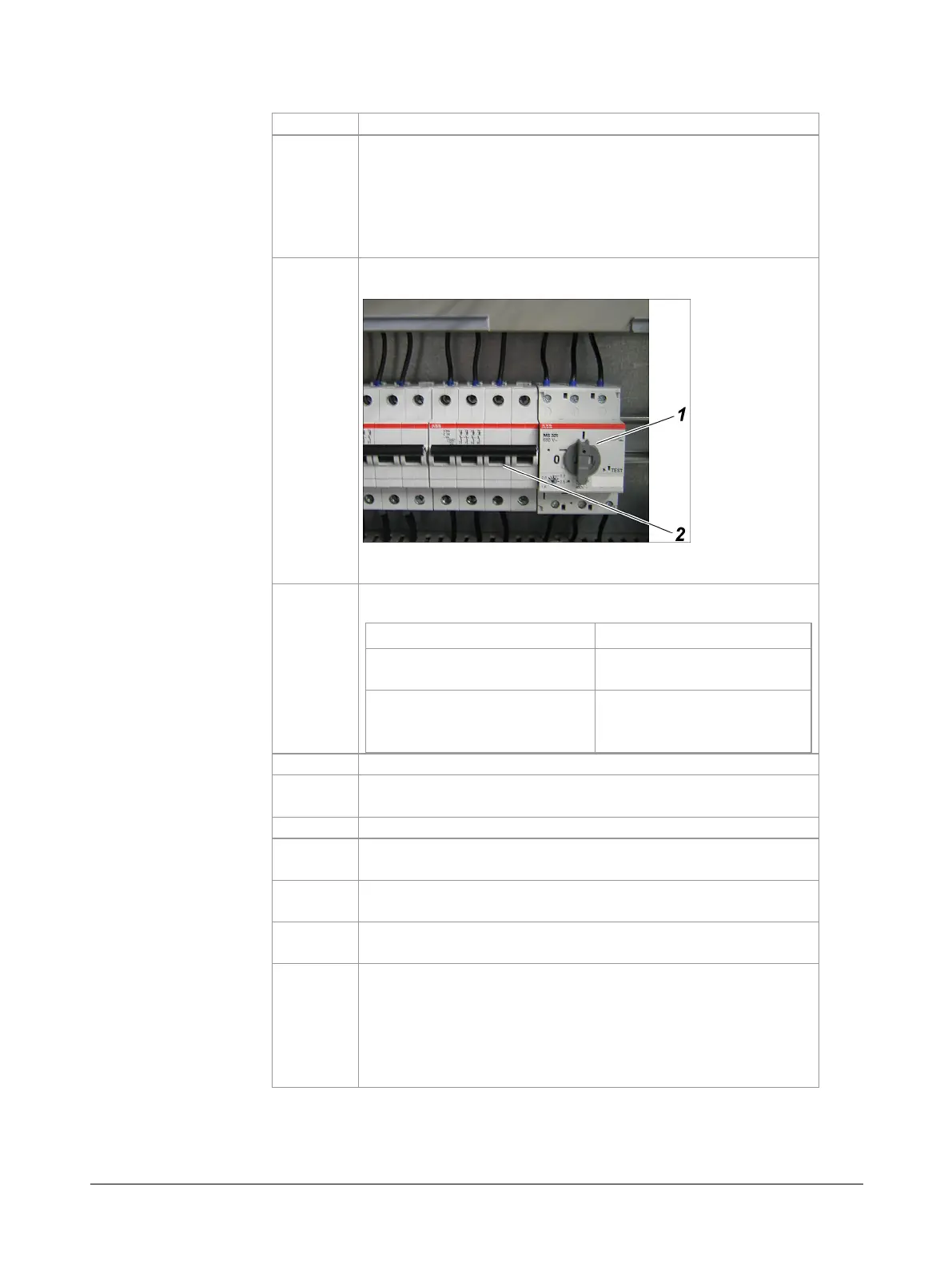

Switch off the cooling-water pump

-M51

at the motor

breaker

-F37

.

Note:

You can also switch off the cooling-water pump at

circuit breaker

-F36

(2)

.

Sight-check the cooling-water circuit.

you locate a leak, replace component and

no leak was found but pres-

sure continues to drop in

Drain the cooling-water circuit.

Fill cooling-water circuit with compressed air, max. 3 bar

(3000 hPa).

Spray cooling-water circuit with leak detection spray.

If you locate a leak: replace component and ensure ade-

Fill up cooling water again and vent (see

Preparing the

cooling-water circuit

on page 114).

Switch the cooling-water pump

-M51

on again at motor

breaker

-F37

or circuit breaker

-F36

.

Turn service switch back to

OFF

position and insert probe

again using the controller.

WARNING!

Probe moves into the kiln.

Do not stand in the

area of travel of the probe or probe carriage until the probe

is completely inserted into the kiln and the warning lamps

checking the cooling-

water circuit

Loading...

Loading...