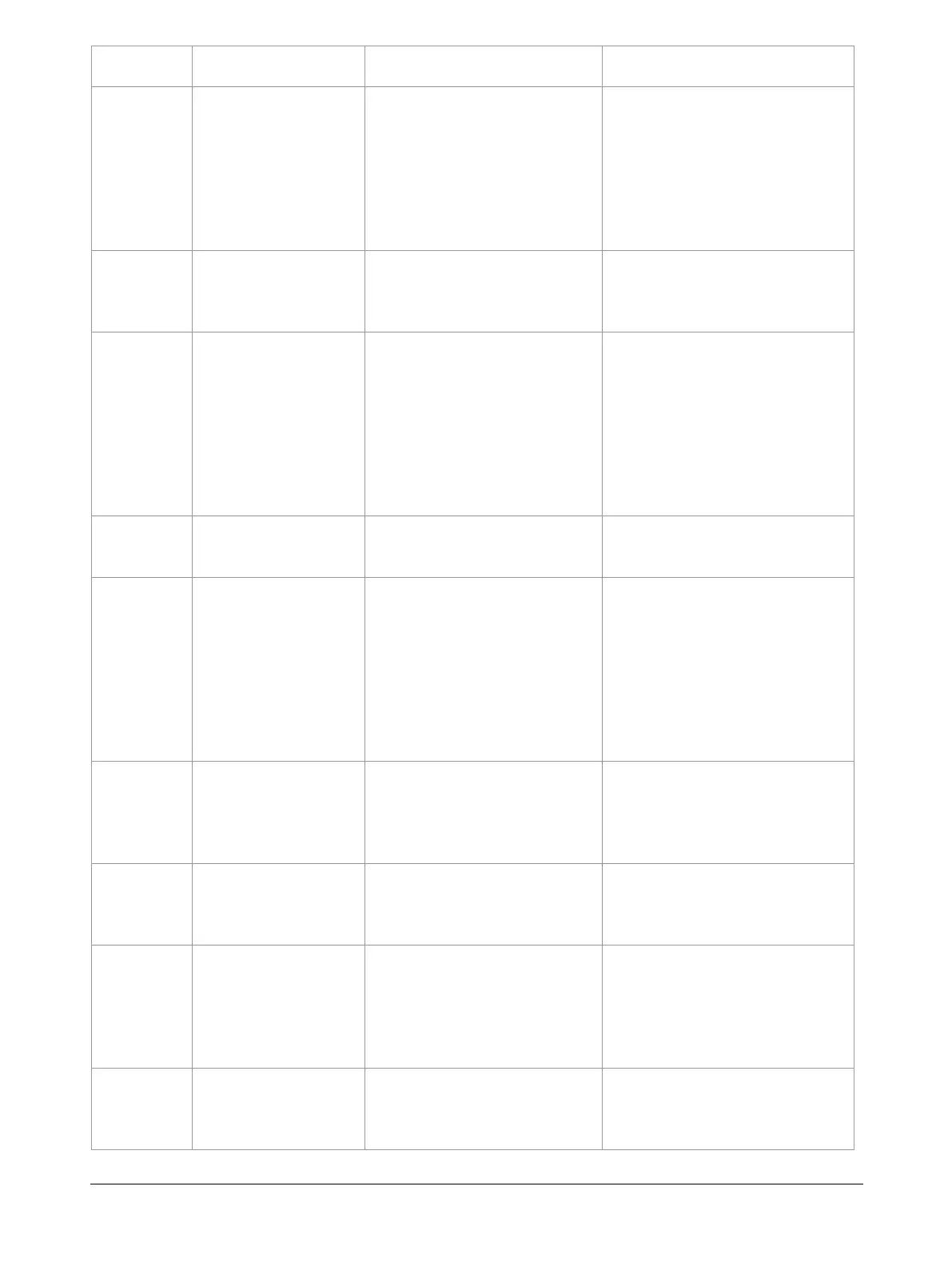

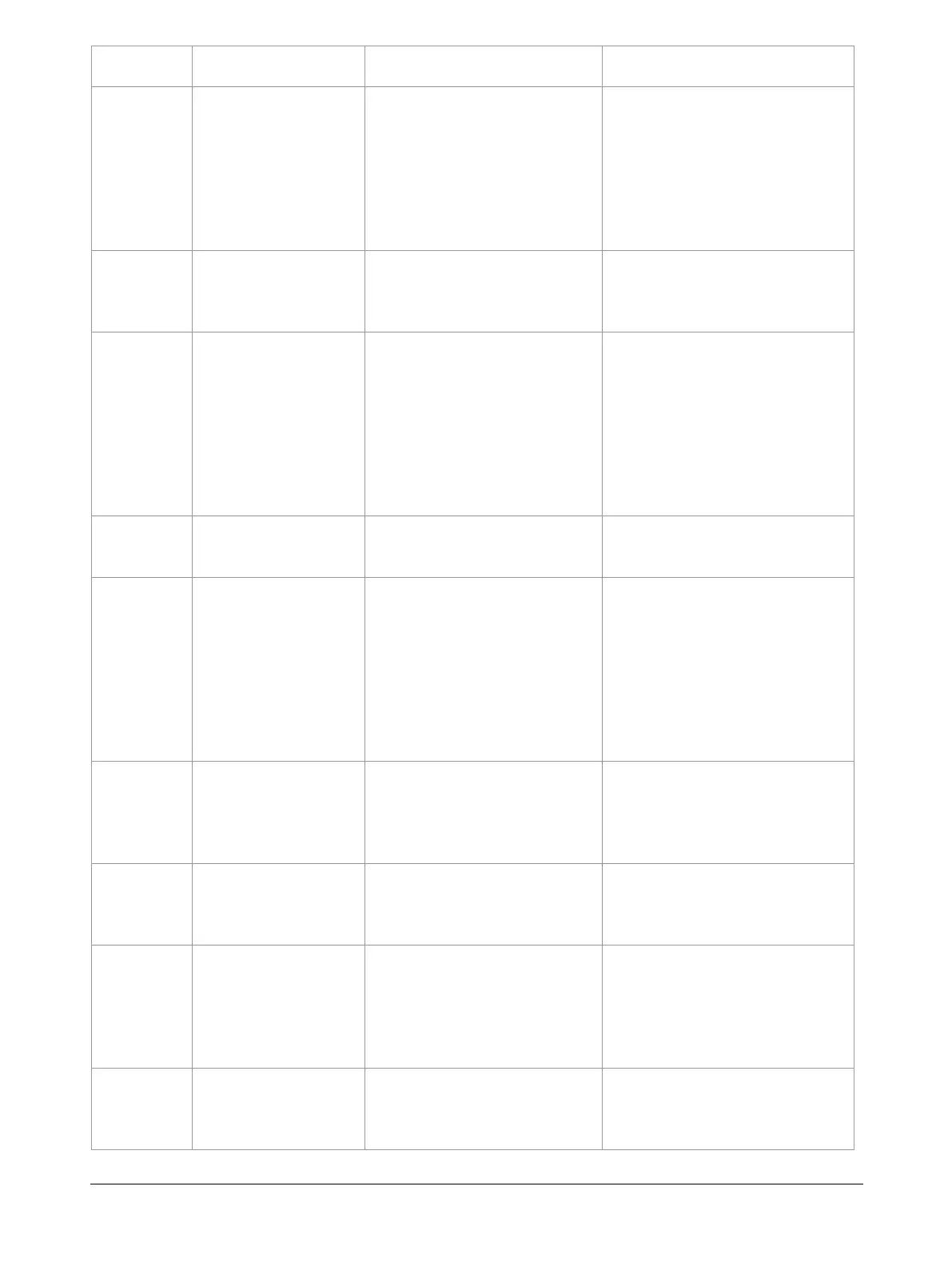

-EN Rev. E Operating instruction SCK Gas Sampling System 219

Plain text (not

stored in controller)

pressed Air

Emergency

Tank

pressed-air emer-

gency tank pressure

not adequate

If the central compressed-

air supply is also faulty,

first remedy the cause for

failure of the central com-

pressed-air supply

Leak in tank supply pipes

or tank itself

Pressure switch 578 error

Check central compressed-

air supply

Check supply pipe to com-

pressed-air emergency tank

for leaks

Check functioning and set-

ting of pressure switch 578

Probe Pres-

sure MIN

alarm low pressure

not reached

clogged

Sample gas line clogged

clean gas sampling probe

Check and, if necessary,

Probe Heat-

ing Temp.

MIN

Probe heating tem-

perature too low

At start-up probe heating

not switched on long

enough

Probe heating defective

Defect in temperature

controller

Heating connection cable

damaged

Wait for heating-up time

(approx. 20 min)

Check probe heating for

proper functioning

Probe Heat-

ing Temp.

Probe heating tem-

perature too high

Probe heating overheating

Check PT100 sensor

ing Temp.

MIN

perature too low

At start-up probe heating

not switched on long

enough

Probe heating defective

Defect in temperature

controller

Heating connection cable

damaged

(approx. 20 min)

Check probe heating for

proper functioning

Chain Sam-

Temp. Error

sample gas line

temp. error

not switched on long

enough

Cable drag chain heating

(approx. 20 min)

Check heating for proper

functioning

tion Switch

Probe Ac-

tion

limit switch error

Front and at least one of

the two rear limit switches

for probe movement trig-

gered simultaneously

Check function and position

of limit switches

Check position of trigger

element

Cleaning

Not Suc-

cessful

Probe H

after 3x cleaning

longer clean probe H ade-

quately

Remove dirt sticking to the

gas inlet

Clean the filter element

Check compressed-air sup-

ply and solenoid valves of

tion Switch

Plunger

Action

limit switch error

limit switches triggered

simultaneously

Check function and position

of limit switches

Loading...

Loading...