Installation and Commissioning Guide

Split Tri-Capacity

81

Installation and Commissioning Guide 500-700 Tri-Capacity Split Ducted

Doc. No.0525-098 Ver. 2 210330

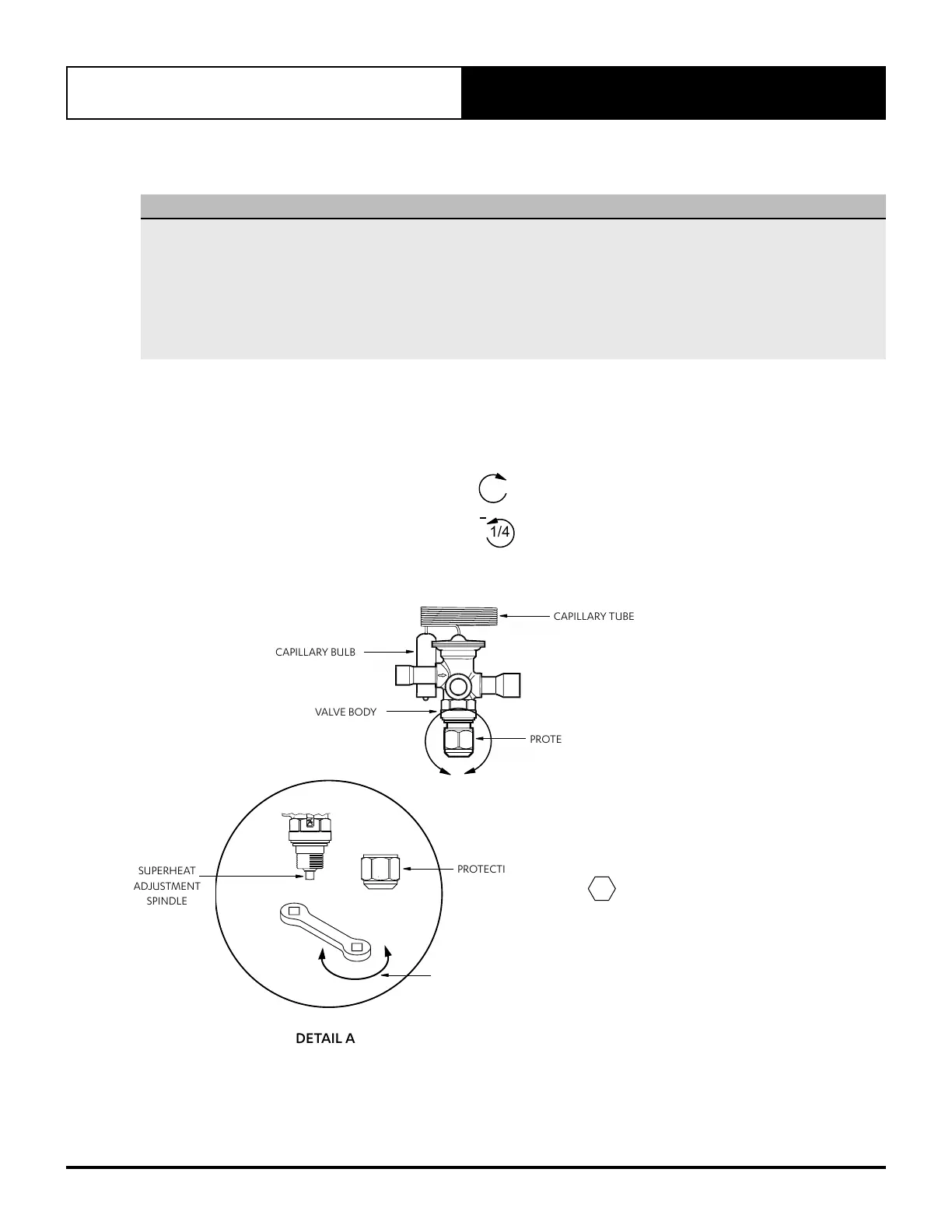

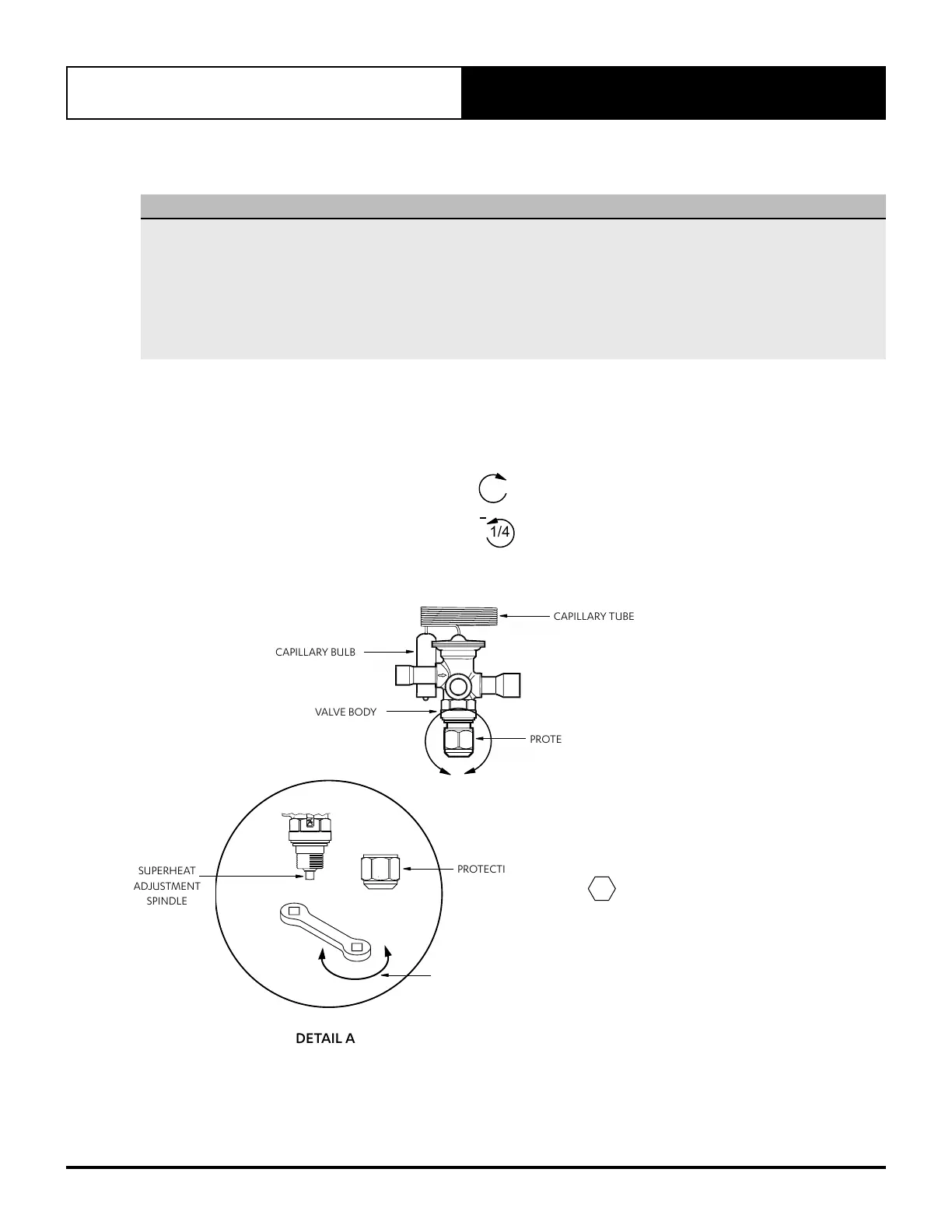

28.03. Thermal Expansion Valve (TXV) Adjustment

CAUTION

• Allow the systems to stabilise for 20 minutes before adjusting the thermal expansion valve (TXV) in order to ensure

correct subcooling and superheat conditions. Turn Superheat Adjustment spindle 1/4 turn at a time, stabilising the

systems in between adjustment, check condition, adjust again if necessary, until correct subcooling and superheat

conditions are attained.

• A total of 4 Thermal Expansion Valves are provided for the Outdoor and Indoor unit combination (2 per unit).

Fo r example:

Outdoor Unit = 1 x TXV for Small Compressor (Crt. 1) + 1 x TXV for Large Compressor (Crt. 2)

Indoor Unit = 1 x TXV for Small Compressor (Crt. 1) + 1 x TXV for Large Compressor (Crt. 2)

Subcooling Adjustment

(Refer Subcooling Adjustment to Refrigerant Charging Section).

Superheat Adjustment

If superheat is lower than 2k = turn Adjustment Spindle

1/4

+

, stabilise system for 20 minutes, adjust if required.

If superheat is higher than 8k = turn Adjustment Spindle

1/4

, stabilise system for 20 minutes, adjust if required.

See Diagram Below:

© Danfoss A/S (AC-BNM/mr), 01 - 2008 DKRCC.PI.AN0.A4.02 / 520H2448 1

Instructions

TR 6

067R9508

067R9508

PS = 42 bar /( MWP = 610 psig)

p

test

= max. 47 bar (680 psig)

Reverse: B→A

Normal: A→B

Flow direction:

Q

nom.

A → B [kW] = 100%

Q

nom.

B → A [kW] = 80%

Adjustable setting

Fixed setting

CAPILLARY BULB

VALVE BODY

CAPILLARY TUBE

PROTECTIVE CAP

A

14 TURN AT A TIME

SUPERHEAT ADJUSTMENT

2 DKRCC.PI.AN0.A4.02 / 520H2448 © Danfoss A/S (AC-BNM/mr), 01 - 2008

SS = 2°C (3.6°F) or according

to customer speci cation

Number of turns

from SS to

tight spring

Number of turns

from SS to

loose spring

R22 +7.25 –4.25

R410A +9.5 –2

DETAIL A

SUPERHEAT

ADJUSTMENT

SPINDLE

PROTECTIVE CAP

- 1/4

Turn

+ 1/4

Turn

= 19MM 34”

T = 10NM 7 FTLBF

Loading...

Loading...