192 Agilent 7890 Series Troubleshooting

8 Troubleshooting Tasks

To Check a Split Vent Line for Contamination

This procedure applies to the multimode and split/splitless

inlets.

1 Gather the following:

• 7/16-inch wrench

• Wrench, hex for changing septum

• Heat-resistant gloves if the inlet is hot

• Cleaning brushes

2 Load the inlet maintenance method and wait for the GC to

become ready.

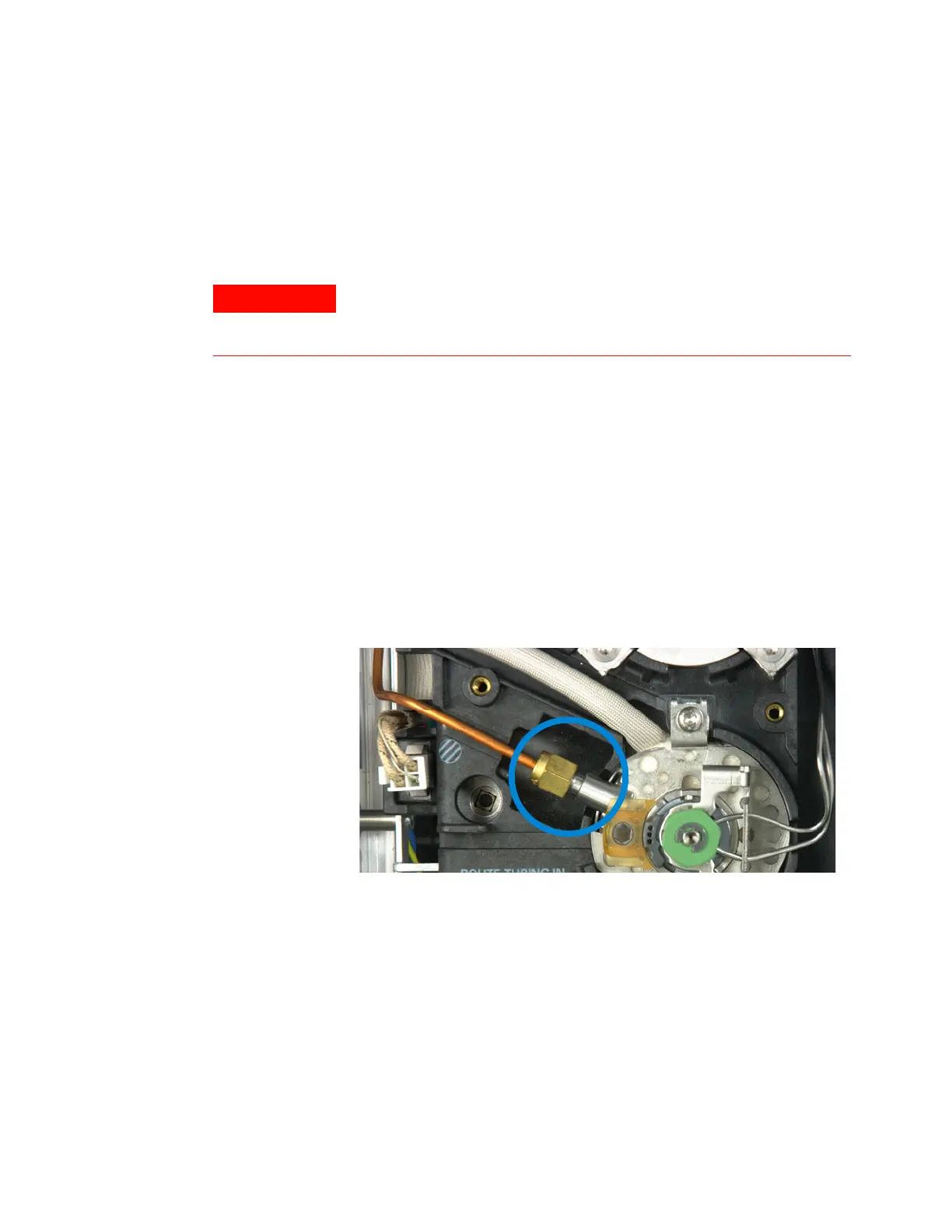

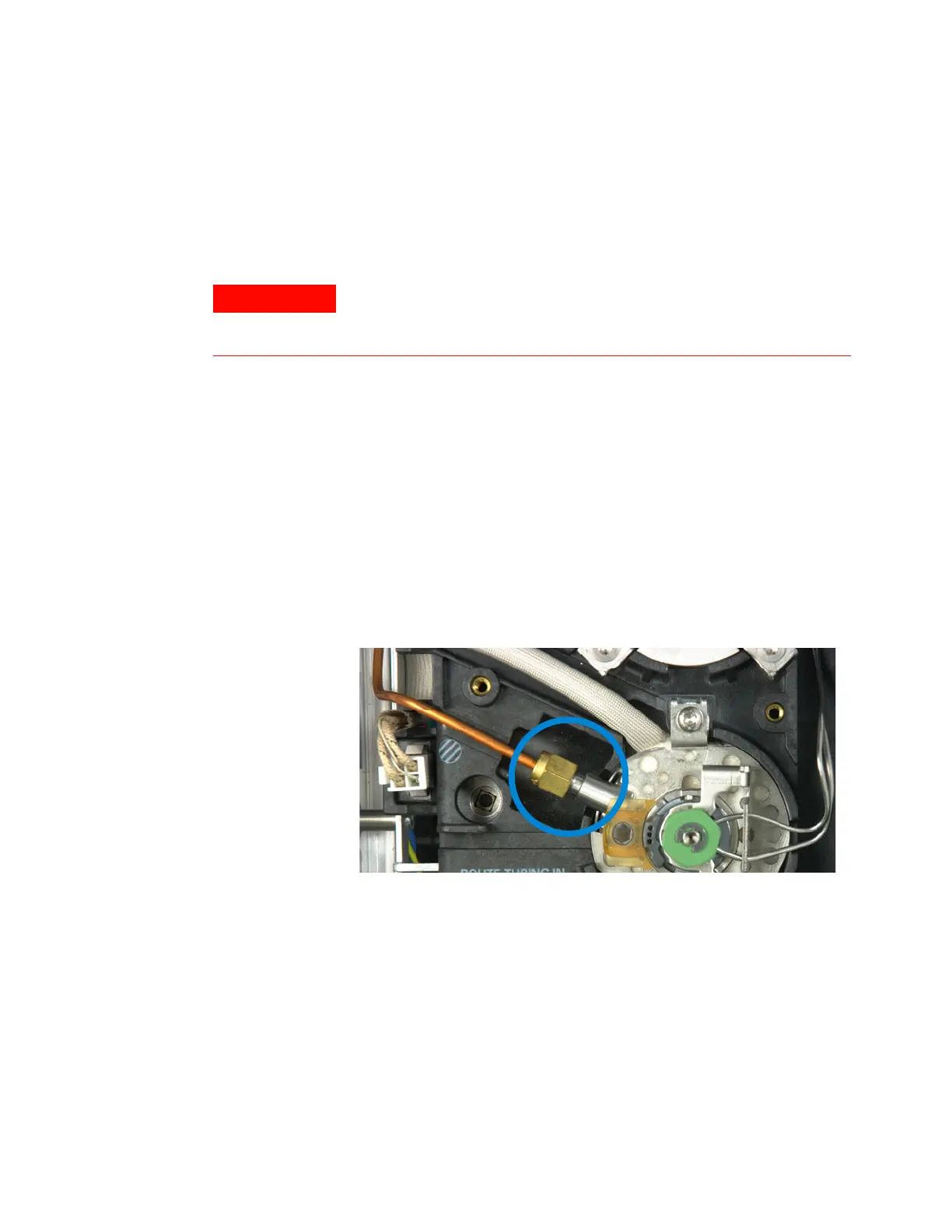

3 Loosen the 1/8-inch Swagelok nut that seals the copper split

vent line to the injection port.

4 Inspect the 1/8-inch copper split line for condensed sample.

Flush or replace the copper split vent line.

5 Remove the septum head.

6 Check the split tube fitting in the shell weldment for

blockage. Clean the split tube with a brush and suitable

solvent.

7 Reassemble the split/splitless inlet and run the split vent

restriction test to test for restrictions in the split vent flow

path. If the inlet still fails, suspect flow module

contamination or defects.

Be careful! The oven, inlet, and/or detector may be hot enough to

cause burns. If the oven, inlet, or detector is hot, wear

heat-resistant gloves to protect your hands.

Loading...

Loading...