Inlets 3

Advanced Operation Manual 105

Cold splitless introduction

For cold splitless introduction, use an initial inlet

temperature below the normal boiling point of the solvent.

For most solvents, starting the first inlet temperature ramp

at 0.1 minutes provides good transfer and reproducibility. A

program rate of 500 °C/min or higher is appropriate for

thermally stable analytes. A final temperature of 350 °C,

held for 5 minutes, has quantitatively transferred up to C

44

alkane.

A main advantage of temperature programmability is that

the inlet can be heated gently to transfer delicate analytes. If

the oven temperature is initially low enough to refocus the

analytes on the column, the inlet heating rate can be made

slower (e.g., 120 °C/min). This reduces thermal degradation

from the inlet and can improve peak shape and quantitation.

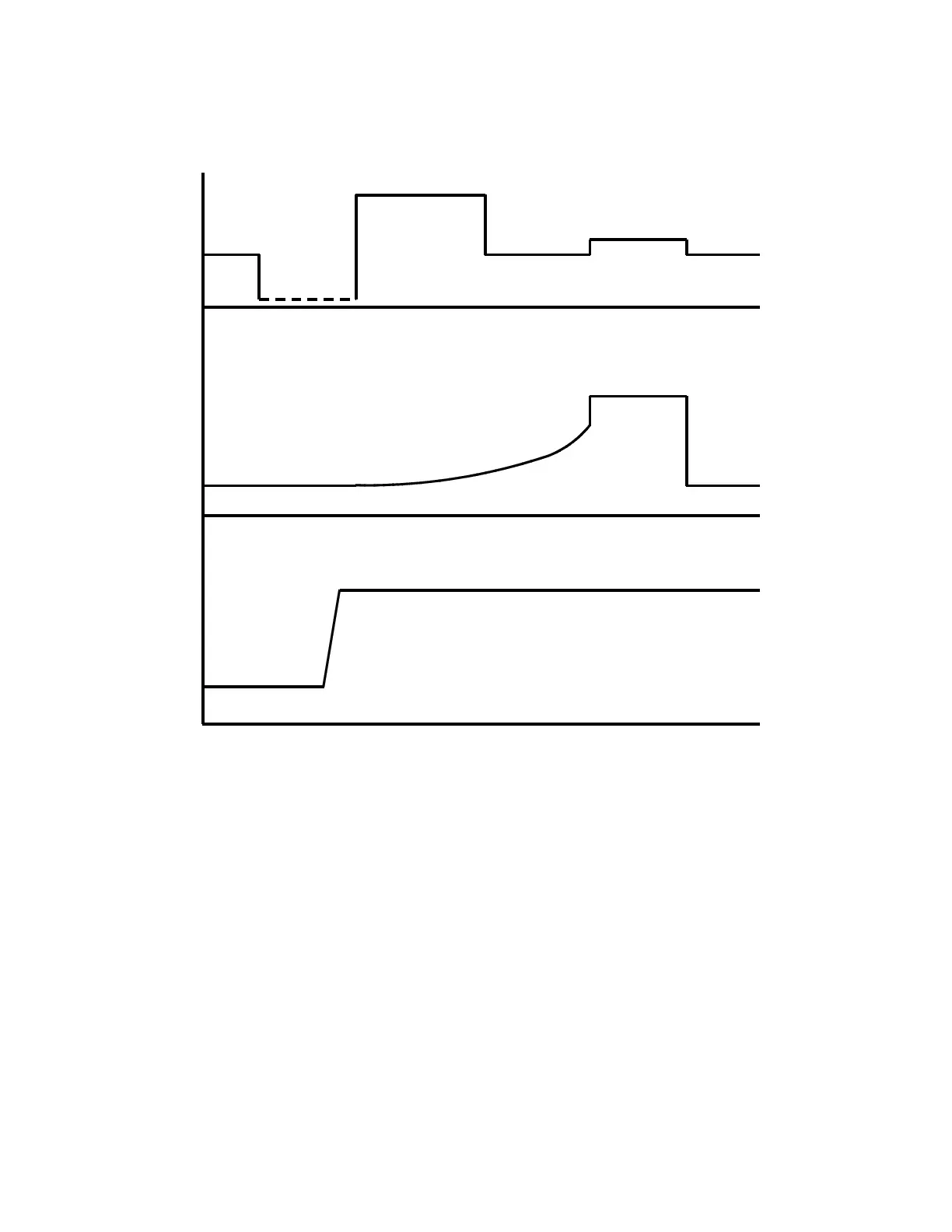

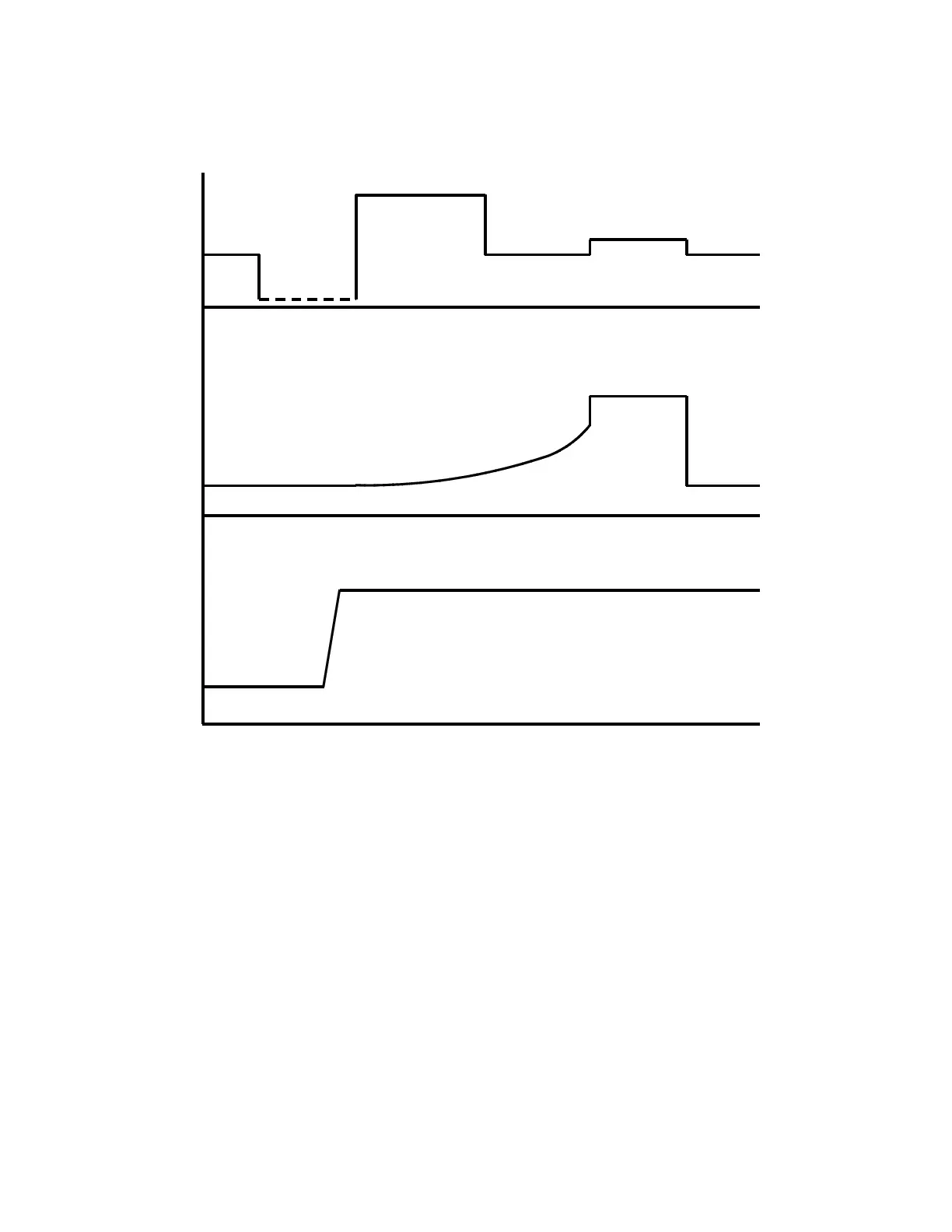

Split vent flow

Purge flow

Saver flow

Inlet pressure

Inlet is

pressure

controlled

Post pressure

Inlet pressure

Inlet

temperature

Final temp 1

Initial temperature

Prep

Run

Start

Run

Purge

Time

Saver

Time

Stop

Run

Post

Time

Post

Time

Stop

Run

Purge

Time

Purge

Time

Prep

Run

Prep

Run

Start

Run

Start

Run

Column mode = Constant flow

Loading...

Loading...