Inlets 3

Advanced Operation Manual 111

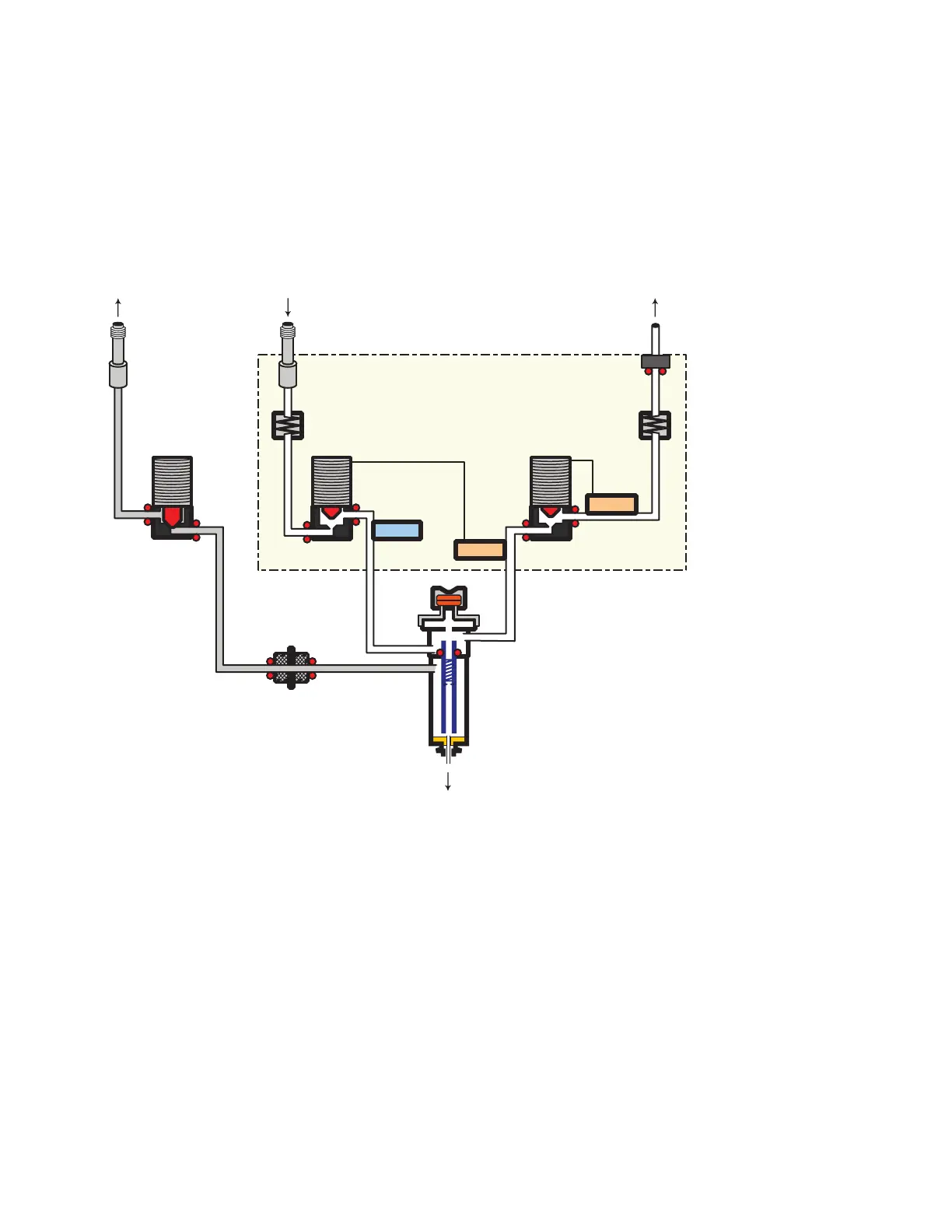

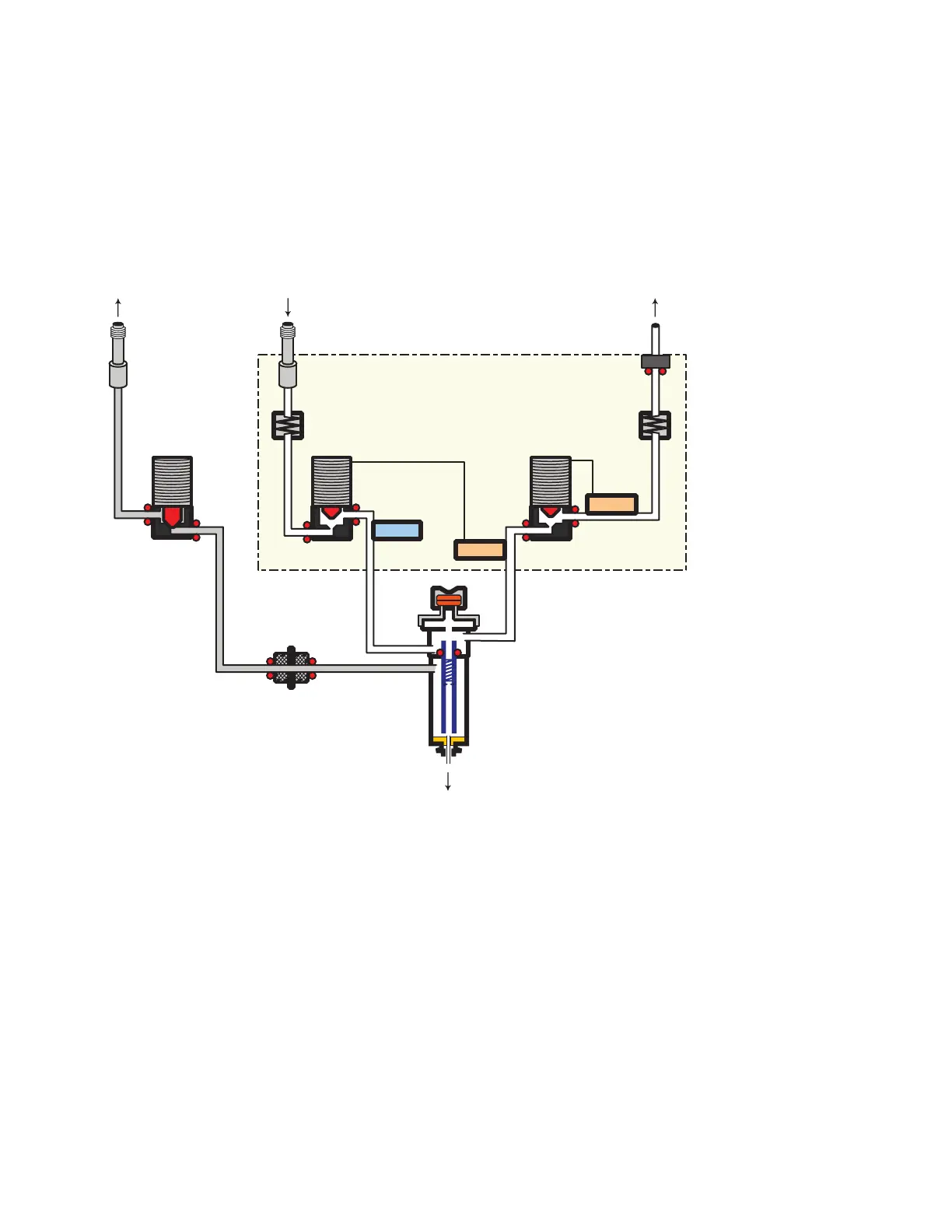

Stage 2. Sample transfer

When solvent venting ends, the split valve vent closes and

the inlet heats to Final temperature 1. The sample transfers to

the capillary column during Purge delay time.

Stage 3. Purge and cleanup

The split valve opens again and the system returns to the

Stage 1 configuration but with different setpoints. The PTV

inlet is flushed. Additional ramp rates are available to

thermally clean the inlet or to reduce inlet temperature after

sample transfer. This can extend the life of the liner.

Temperature, pressure, and flow considerations

The solvent vent mode goes through three distinct pneumatic

states; venting, sample transfer, and purging. The vent

portion allows the inlet pressure and the vent flow to be

adjusted to optimize solvent elimination. The transfer state

Valve

Frit Frit

Valve

EPC Module

Valve

Split Vent Trap

PTV Inlet Weldment

FS = Flow Sensor

PS = Pressure Sensor

FS

PS

PS

Split

Carrier Supply

80 PSI

Septum Purge

Column

Loading...

Loading...