Inlets 3

Advanced Operation Manual 61

Cold split introduction

For cold split sample introduction, use an initial inlet

temperature below the normal boiling point of the solvent. If

the liner volume is enough to hold all the vaporized solvent,

start the first inlet temperature ramp at 0.1 minutes with a

high heating rate (500 °C/min or higher). The final

temperature should be high enough to volatilize the heaviest

analytes from the liner and should be held for at least

5 minutes. A final temperature of 350 °C for 5 minutes has

proven sufficient to quantitatively transfer C

44

.

For larger injection volumes or to eliminate the solvent, hold

the initial temperature long enough to vent the solvent

through the split vent and then begin the first ramp. Use a

fast rate for thermally stable analytes. Slower rates may help

minimize thermal degradation in the inlet.

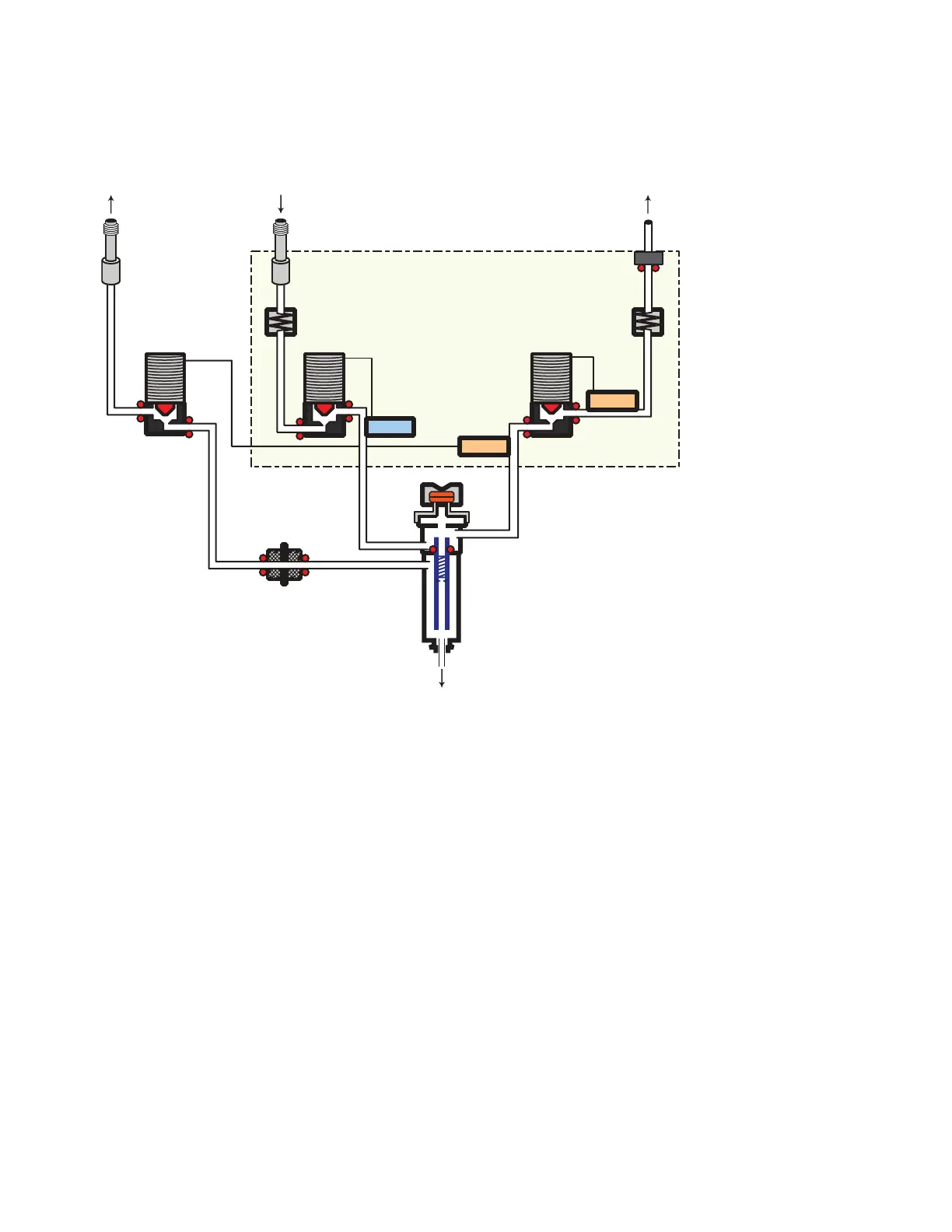

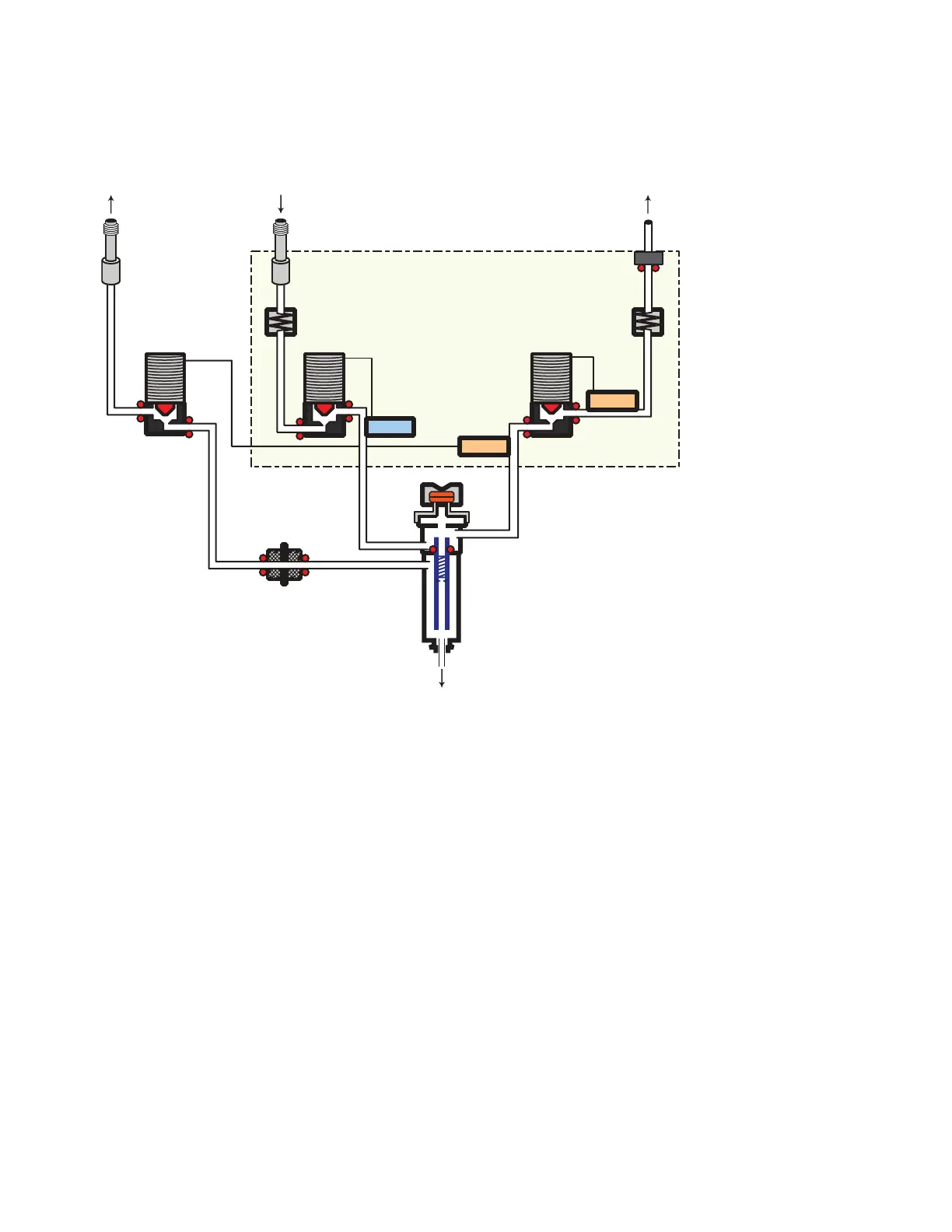

Split

Carrier supply

80 PSI

Septum Purge

Valve

Frit

EPC Module

PS

Inlet Weldment

Column

Split Vent Trap

FS = Flow Sensor

PS = Pressure Sensor

Valve Valve

Frit

PS

FS

Loading...

Loading...