Rockwell Automation Publication 20B-IN026C-EN-P - October 2015 85

Converter Assembly Component Replacement Procedures Chapter 4

Install Components

1. Use isopropyl alcohol to clean the surface where the new Snubber

Resistor(s) will be installed.

2. Verify that the mounting surface of the new Snubber Resistor(s) is clean. If

not, clean with isopropyl alcohol.

3. Use a 3-inch paint roller or putty knife to apply a thin even coating of the

supplied thermal grease to the mounting surface of the new Snubber

Resistor(s) and install.

4. Install the new Snubber Resistor(s). Torque the mounting screws to

2.9 N•m (26 lb•in).

5. Reconnect all wires for the Snubber Resistor(s).

6. Reassemble remaining components in reverse order.

7. Replace all safety shields and enclosure covers before applying power to the

drive.

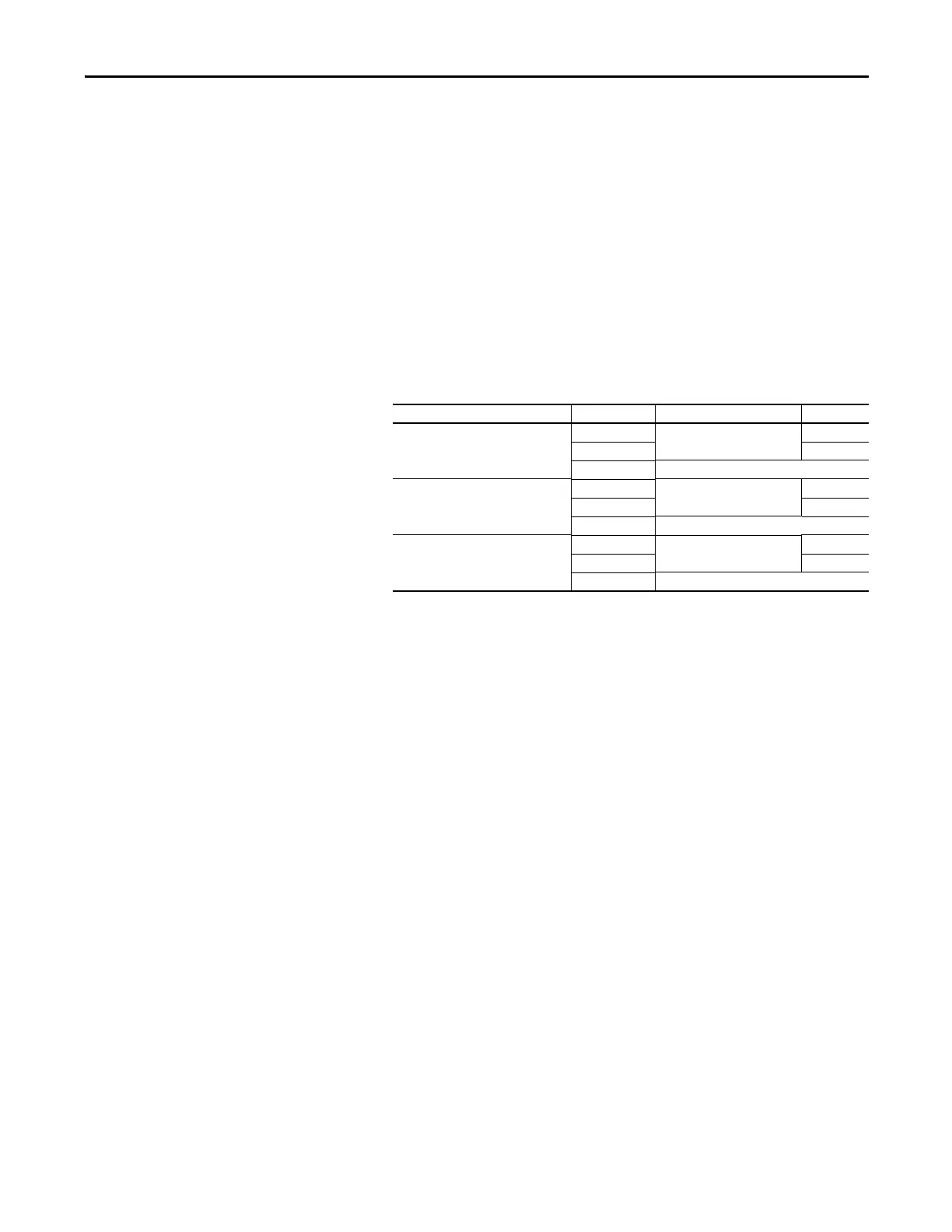

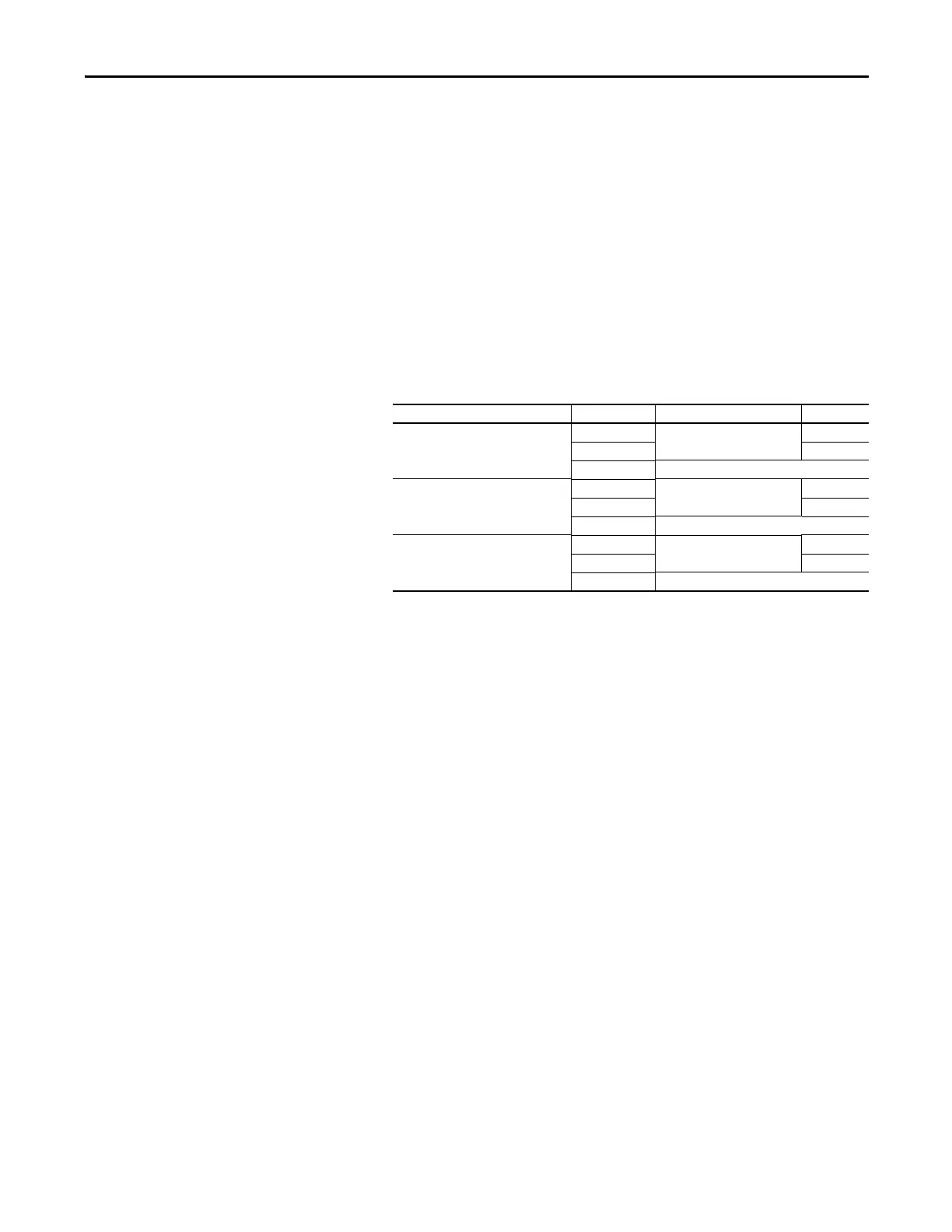

From Wire Color To Terminal

Snubber Resistor (R) Black Snubber Board (R) J1

Blue J2

Red AC Busbar (R)

Snubber Resistor (S) Black Snubber Board (S) J1

Blue J2

Red AC Busbar (S)

Snubber Resistor (T) Black Snubber Board (T) J1

Blue J2

Red AC Busbar (T)

Loading...

Loading...