Rockwell Automation Publication 20B-IN026C-EN-P - October 2015 57

Inverter Assembly Component Replacement Procedures Chapter 3

Install Components

1. Carefully examine the Transitional Busbar Assembly and Bus Capacitors

for damage.

When replacing any IGBT module, we recommend that you replace all

Bus Capacitors. If needed, see Bus Capacitors on page 51

to replace

damaged Bus Capacitors.

2. Install the IGBT module.

a. Use isopropyl alcohol to thoroughly clean the surface of the Heatsink.

b. Verify that the mounting surface of the new IGBT module is clean. If

not, clean the mounting surface with isopropyl alcohol.

c. Use a 3- or 4-inch paint roller or putty knife to apply a thin even coating

of the supplied thermal grease to the mounting surface of the IGBT

module.

In the next step, take care to not disturb any of the thermal grease on the

IGBT module.

d. Place the IGBT on the chassis with the serial number label at the top.

Install with supplied screws using this torque sequence:

If the Transitional Busbar Assembly was not removed, take care to not

damage the Flexible Capacitor Busbars fitting over and under the

Transitional Busbar Assembly.

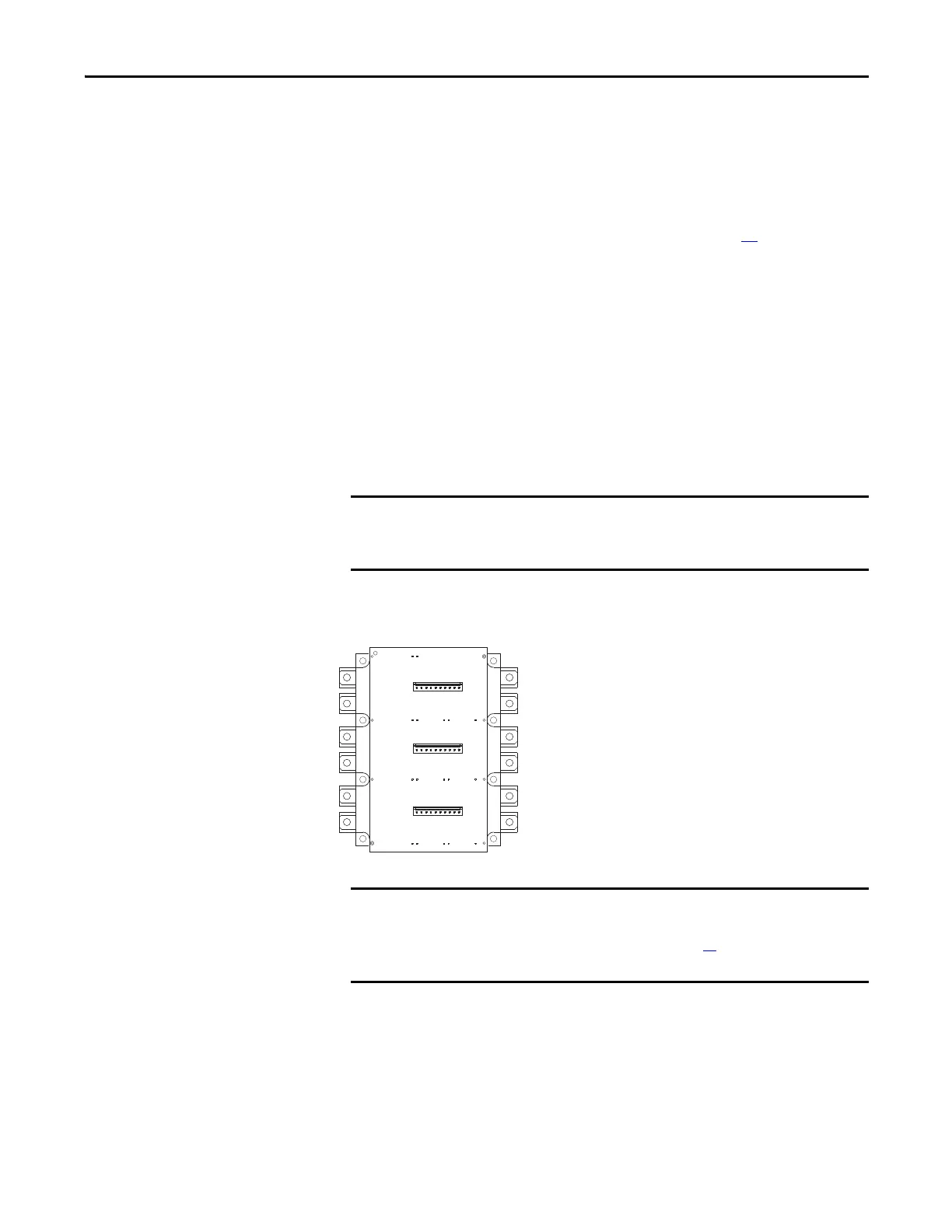

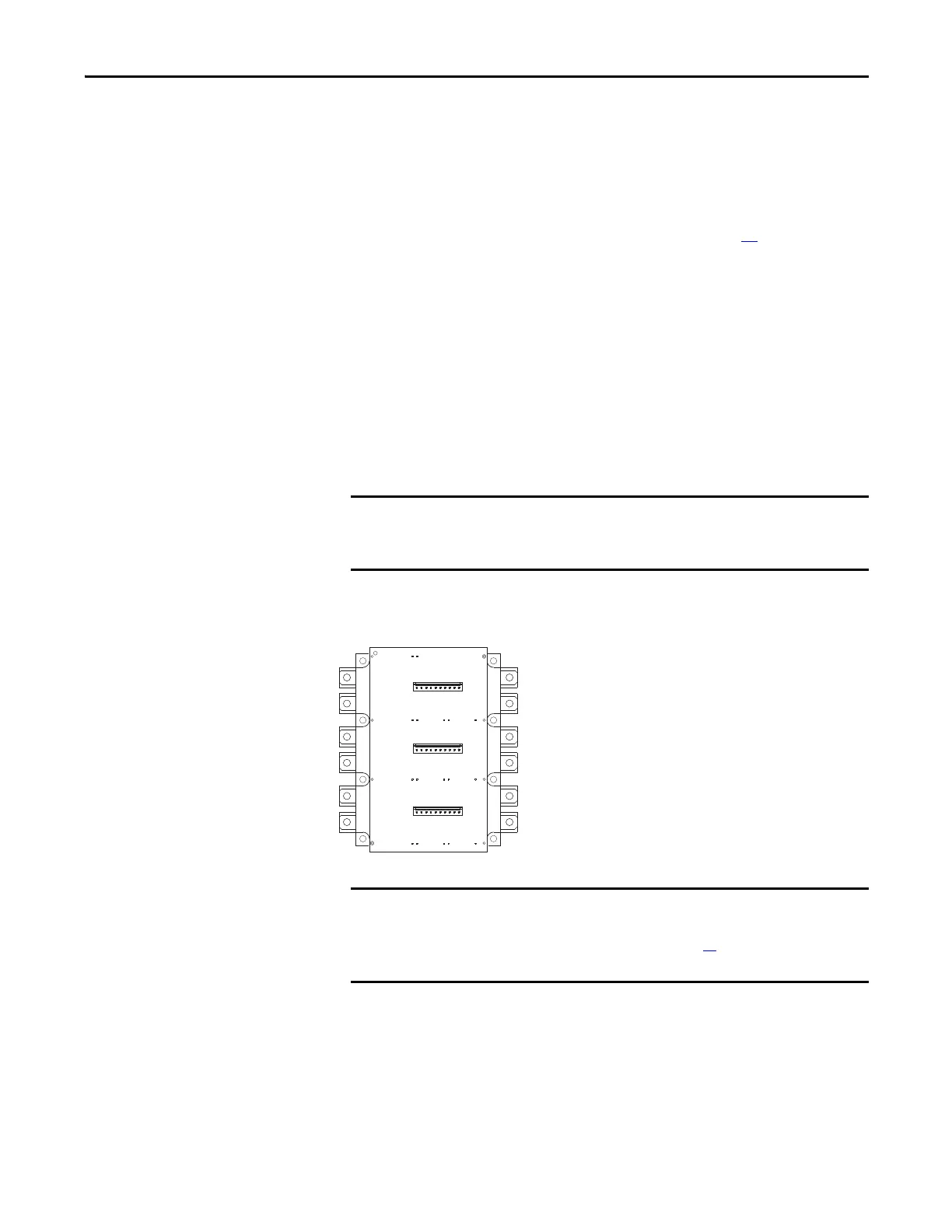

➑

➋

➍

➏

➎

➌

➊

➐

IGBT Torque Sequence

First Sequence: 0.7 N•m (6.0 lb•in)

Second Sequence: 1.5 N•m (14 lb•in)

Final Sequence: 5.6 N•m (50 lb•in)

The three positive (+) Flexible Capacitor Busbars supplied with the kit must

be installed on the back side of the Transitional Busbar Assembly before

they can be installed on the IGBT. See page 33

for how to install these

busbars on the Transitional Busbar Assembly.

Loading...

Loading...