38 Rev. 2

Calibration

Capacitance-Based Level Calibration

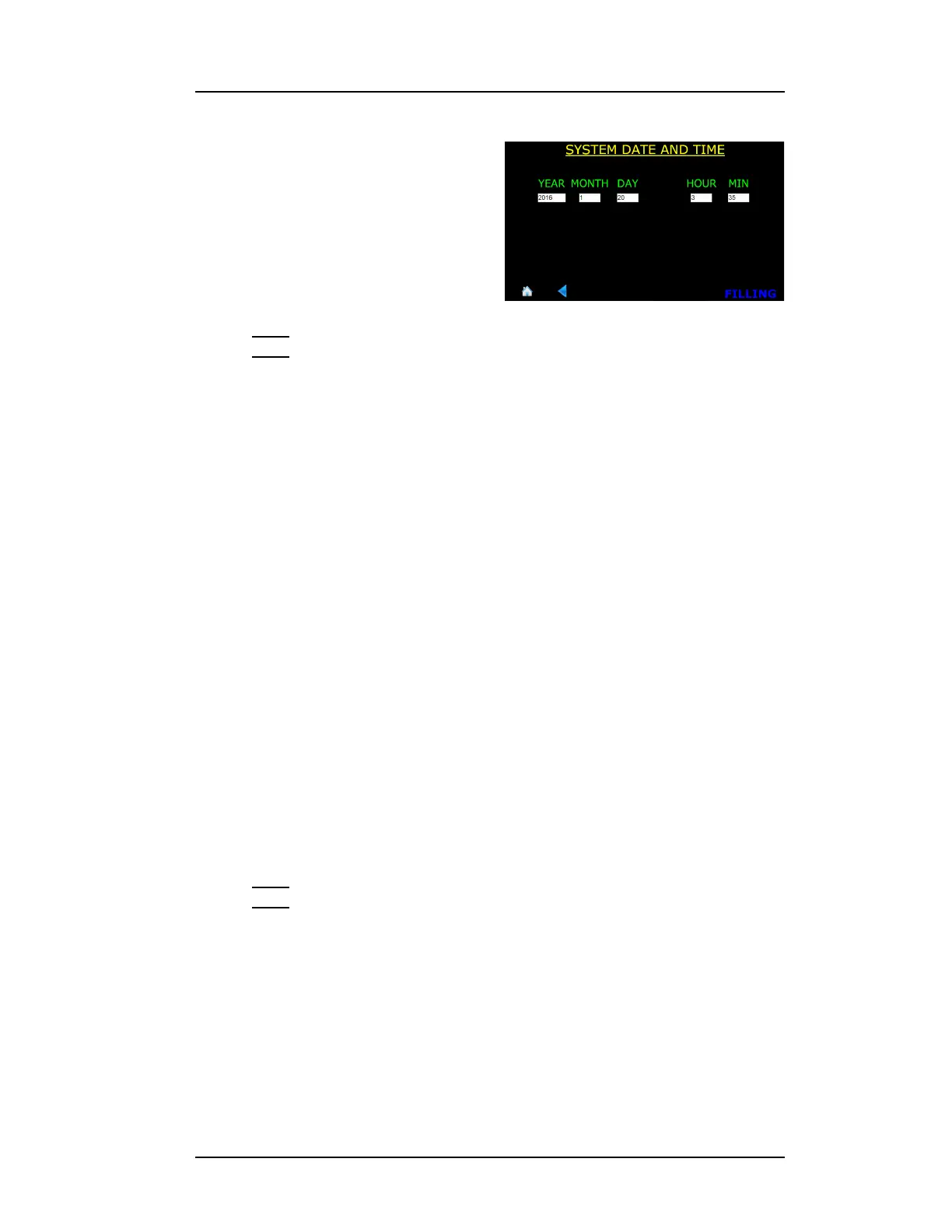

4. Edit the YEAR, MONTH, DAY,

HOUR, and MIN fields as

necessary. Touching in a field

will launch the keyboard on the

screen. Edit the information in

the field as necessary and

choose Enter to enter the data

in the field and close the pop up

keyboard.

Note

The clock is set to GMT at the factory and is battery backed. There is

no provision in the instrument for automatic Daylight Savings Time

correction.

5. Choose SAVE in the footer after all the fields have been edited as

necessary.

4.2 Capacitance-based Level Calibration

4.2.1 Understanding the Sensor Active Length

American Magnetics, Inc. fabricates the liquid level sensor with two vent

holes; a lower vent hole in the side wall near the bottom which is typically

the minimum liquid level calibration point and the upper vent hole in the

sensor side typically near the top of the sensor. The liquid level location

approximately 2.5 cm (1 in) below the upper vent hole is typically the 100%

calibration point.

The Model 1700 Instrument requires the user to enter the calibrated, or

active length, (physical distance between the Min and Max calibration

locations on the sensor) in order for the absolute units function (inches,

cm) to be displayed if desired.

Note

Without an active length entered, the instrument will not be able to

read out in units other than percent.

Figure 4-4. System Menu, Page 2

Loading...

Loading...