16 Rev. 2

Installation

Setting Up an Autofill System

2.5.2 Autofill System Setup

Caution

A relief valve must be used in autofill systems to ensure no cryogenic liquid

can be trapped in a transfer line volume where expansion can cause

damaging pressure. This can occur if the solenoid operated fill valve and the

supply dewar isolation valve are closed, trapping a cryogenic liquid in a

confined volume. All AMI transfer line systems include a relief valve to

preclude this sort of event.

1. Mount the level sensor (8) in the target dewar.

2. Connect the transfer line (11) and fill solenoid valve (12) or supply

manifold to the source dewar.

3. Connect the other end of the transfer line to the fill port (10) on the

valve/manifold of the target dewar.

4. Connect the sensor to the instrument.

a. For distances of 6 feet and less, connect the coaxial cable (6)

between the BNC connector on the liquid level sensor and the

BNC connector on the back of the instrument labeled O/T (3).

b. For distances greater than 6 feet, connect the coaxial cable (9)

between the BNC connector on the liquid level sensor and the

BNC connector on the oscillator / transmitter (7). Use a second

length of coaxial cable (6) to connect between the oscillator /

transmitter (7) and the BNC connector on the back of the

instrument labeled O/T (3).

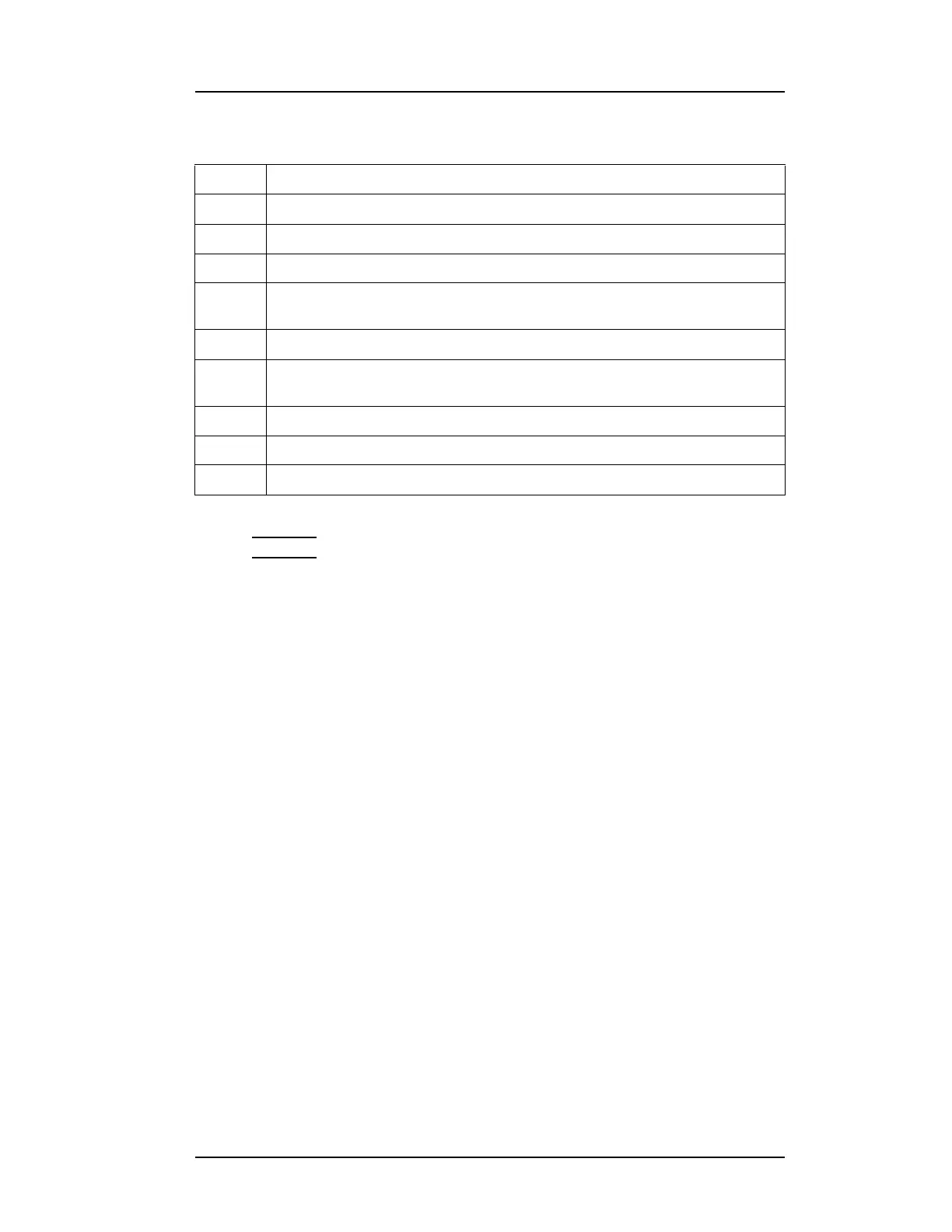

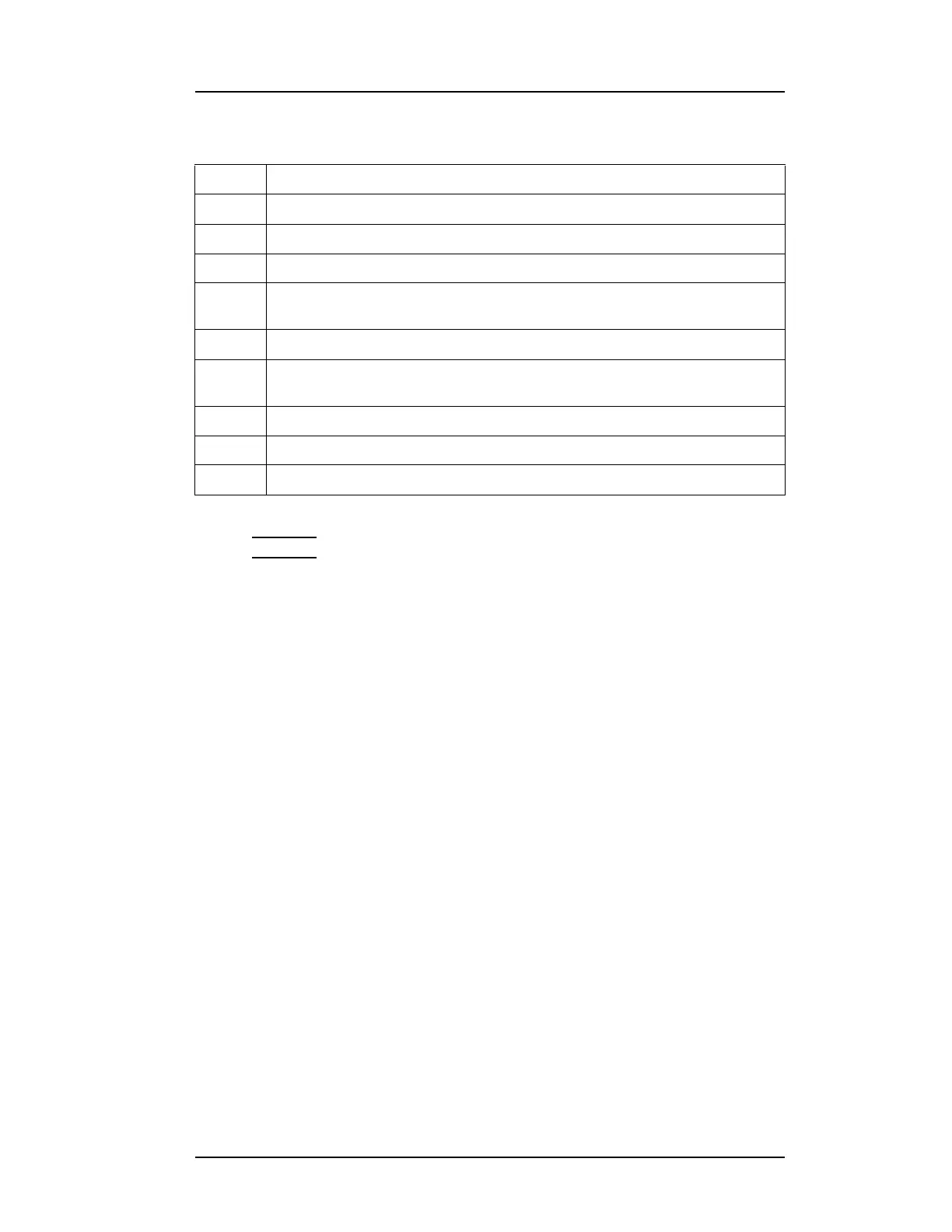

6 Coaxial cable connecting the oscillator / transmitter and the instrument

7 Oscillator / Transmitter (optional; refer to section 2.4.1 on page 13)

8 Level Sensor for level controlled or target dewar

9

Coaxial cable connecting the Oscillator / Transmitter and the liquid level

sensor (optional; refer to section 2.4.1 on page 13)

10 Fill port on target dewar

11

Transfer line attached to the target dewar and the fill solenoid valve on the

source dewar

12 Solenoid-operated fill valve

13 Supply dewar relief valve

14 Supply dewar

Table 2-1. Standard Autofill Setup Description

Number Item

Loading...

Loading...