SECTION 5 – INSTALLATION INSTRUCTIONS

UL EX3470 ULC EX3470

PAGE 5-14 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

INSTALLING THE DETECTION SYSTEM (Continued)

“Scissor” Style Linkage Installation (Continued)

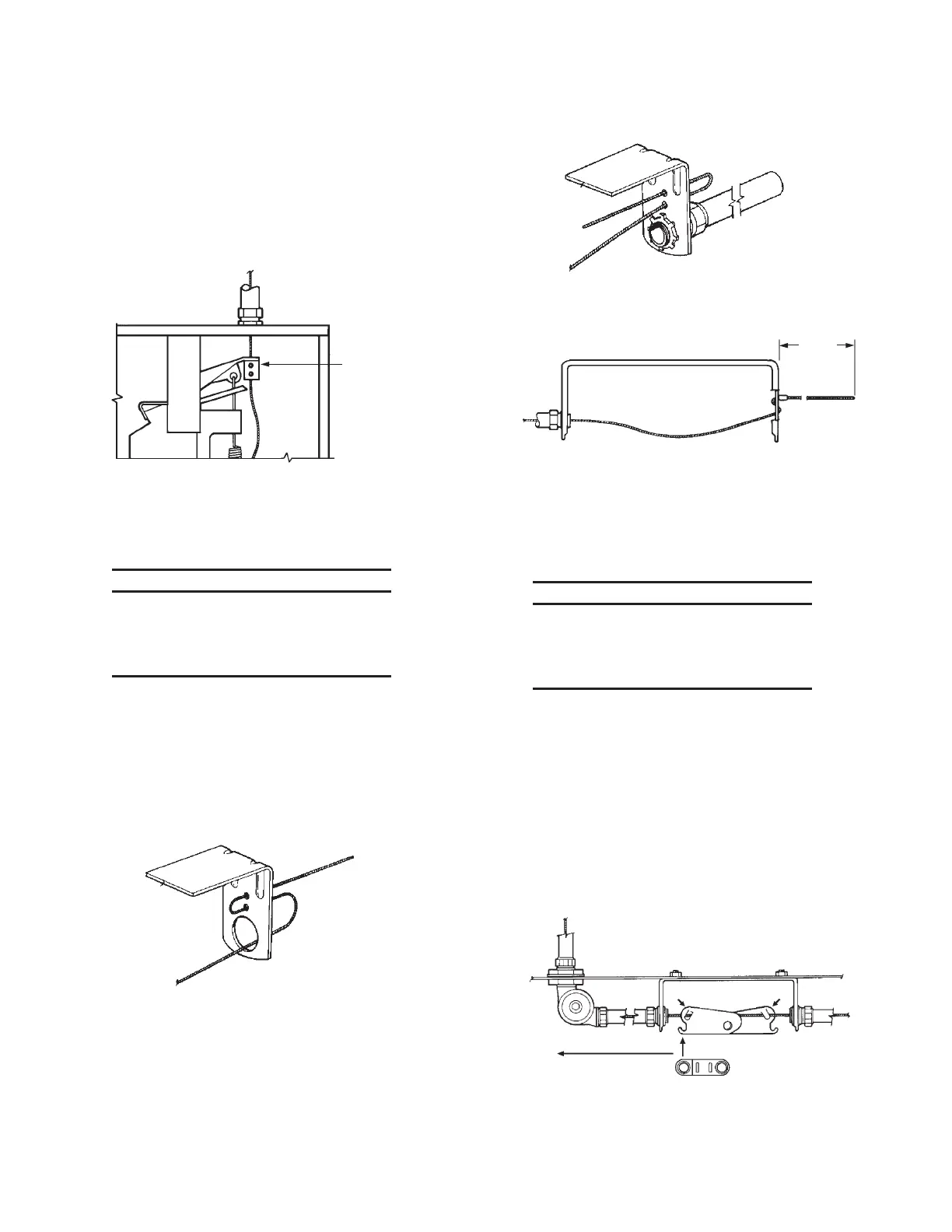

3. Starting at the release assembly, feed the wire rope through

the hole in the release mechanism locking clamp, allowing

the excess wire rope to hang down. (Do not tighten set

screws in locking clamp at this time.) See Figure 5-24.

LOCKING

CLAMP

FIGURE 5-24

000309

4. From the release assembly, run the stainless steel wire rope

through the conduit, pulley elbows and detector brackets to

the terminal detector.

NOTICE

If wire rope requires splicing, make certain

splice is at least 12 in. (305 mm) away from

any pulley elbow or conduit adaptor to avoid

interference.

5. Feed the wire rope through the terminal detector bracket as

shown in Figure 5-25 or as shown in Figure 5-26 if the termi-

nal detector is mounted within a duct or header opening,

and install the stop sleeve approximately 2 to 3 in. (51 to 76

mm) from the end of the wire rope. See Figure 5-27. Use

the National Telephone Supply Company Nicopress Sleeve

Tool (Stock No. 51-C-887) or equal to properly crimp the

stop sleeve.

FIGURE 5-25

000310

FIGURE 5-26

000311

2-3 IN.

(51-76

mm)

FIGURE 5-27

000312

6. To give a constant tension on the wire rope during instal-

lation of the detector linkage, hang a vice grip or other

weighted device on the excess stainless steel wire rope,

leaving an adequate length of spare wire rope between the

locking clamp and the weighted device.

NOTICE

When attaching the weighted device to the

excess wire rope, allow approximately 3 in.

(76 mm) of wire rope for each detector linkage

for proper installation.

Example: If the system has six detectors, there should be

approximately 18 in. (457 mm) of excess wire rope between

the locking clamp and the weighted device, which will be

utilized when the linkage is put in place.

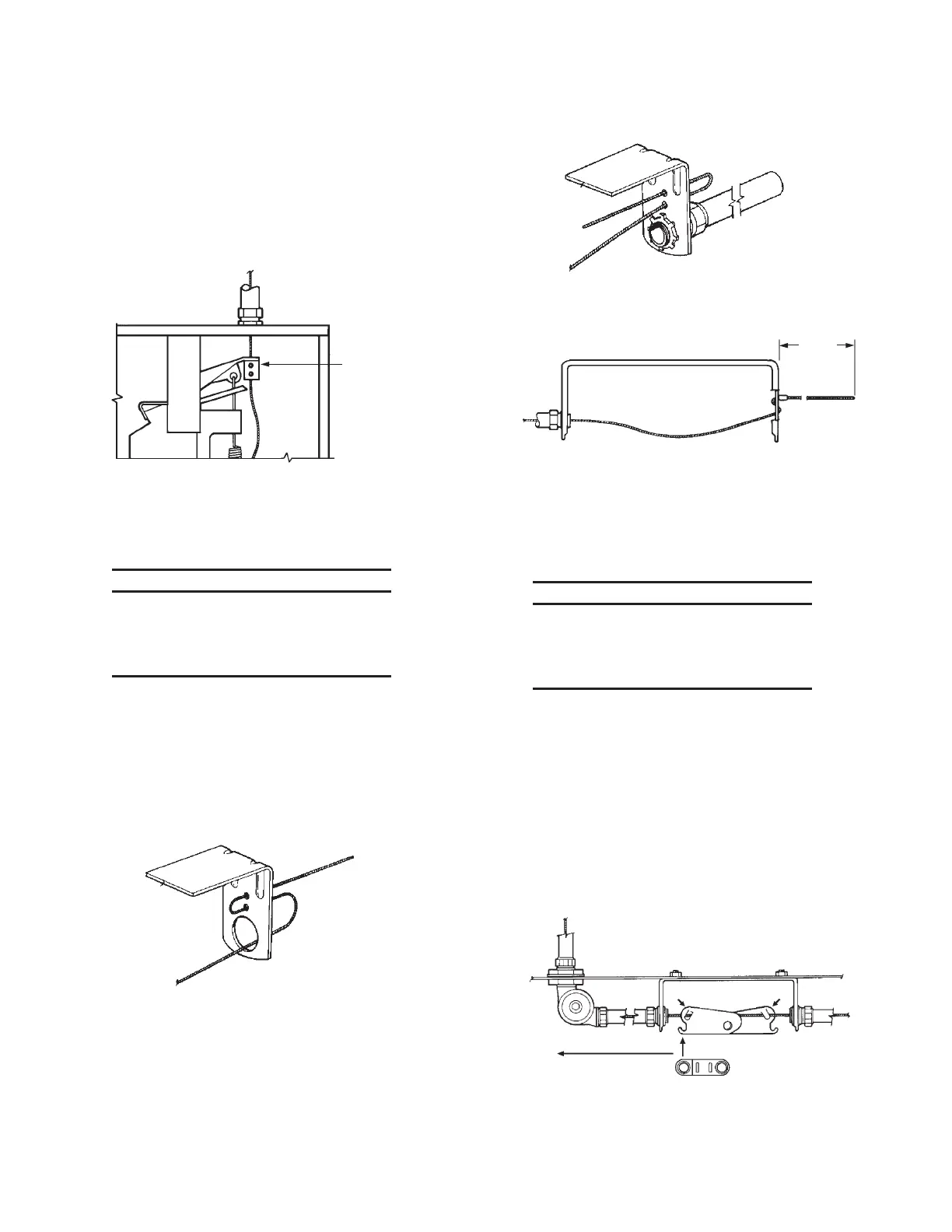

7. Install detector scissor assembly as shown in Figure

5-28. Note that the AUTOMAN release or remote release

assembly is located on the left side of the detector bracket.

Slightly crimp the two assembly “boot-hooks” over the

cable with pliers so the cable is captured under each hook

but the whole assembly can move from side to side. Center

the assembly in the detector bracket.

FIGURE 5-28

000503

AUTOMAN RELEASE OR

REMOTE RELEASE ASSEMBLY

Loading...

Loading...