SECTION 5 – INSTALLATION INSTRUCTIONS

UL EX3470 ULC EX3470

PAGE 5-20 REV. 11 2014-SEP-01

R-102 Restaurant Fire Suppression Manual

INSTALLING MECHANICAL GAS VALVE (Continued)

6. Install the necessary 1/8 in. copper tubing and fittings for

each air cylinder to the accessories piping arrangement on

the regulated release mechanism. See Figures 5-43 and

5-45.

NOTICE

Do not kink 1/8 in. copper tubing or form

a bend too close to a fitting. Secure each

fitting without over tightening. Over tight-

ening could result in pressure leakage or

line separation at actuation.

7.

!

WARNING

To reduce the risk of explosion due to leaking gas, make

certain that the gas line is turned off before connecting

the gas valve. Failure to comply may result in serious

personal injury or death. Gas valve installation shall be

performed by qualified individuals in accordance with local

jurisdiction requirements.

Install mechanical gas valve to its selected location in gas

line so that it ensures safe shut-off to all predetermined

appliances being protected upon actuation of the system.

Mechanical gas valves may be mounted in any convenient

horizontal or vertical position. See Figure 5-46.

a. Use new pipe, properly reamed and cleaned of metal

chips.

b. Make certain gas flow is in the same direction as arrow

shown on gas valve. To avoid cracking the gas valve

casting, do not overtighten pipe connections. If pipe

tape, paste, spray, or similar lubricant is used, extra care

should be taken to avoid overtightening. Apply lubricant

to male threads only.

c. Wrench tighten pipe to gas valve. DO NOT USE GAS

VALVE AS A LEVER WHEN INSTALLING OR VALVE

DAMAGE MAY OCCUR. See Figure 5-46.

d. If strainer is utilized, attach strainer ahead of gas valve.

e. If necessary, install drip leg in gas line in accordance

with the authority having jurisdiction.

f. The total length of wire rope allowed for each valve must

not exceed 150 ft (45.7 m).

g. The maximum number of pulley elbows allowed for each

gas valve is 20.

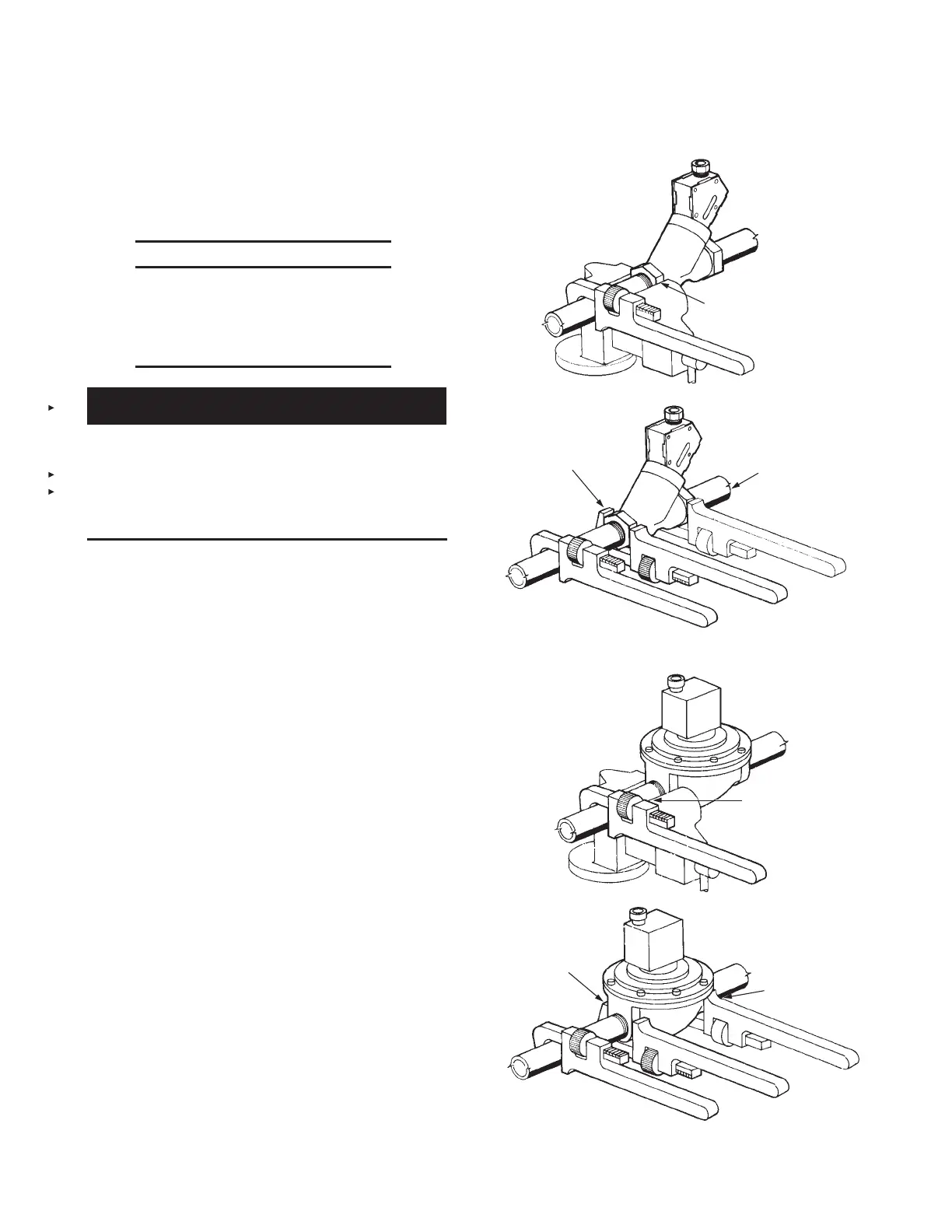

ANSUL MECHANICAL GAS VALVES

000343

CORRECT WAY:

VISE GRIP ENDS NEXT TO PIPE

BEING INSERTED. PREVENTS

EXCESS STRAIN ON VALVE

BODY.

000344

CORRECT WAY:

WRENCH APPLIED NEXT TO PIPE

BEING INSERTED PREVENTS

EXCESS STRAIN ON VALVE BODY.

WRONG WAY:

WRENCH APPLIED

AT THIS POINT

STRAINS VALVE

BODY.

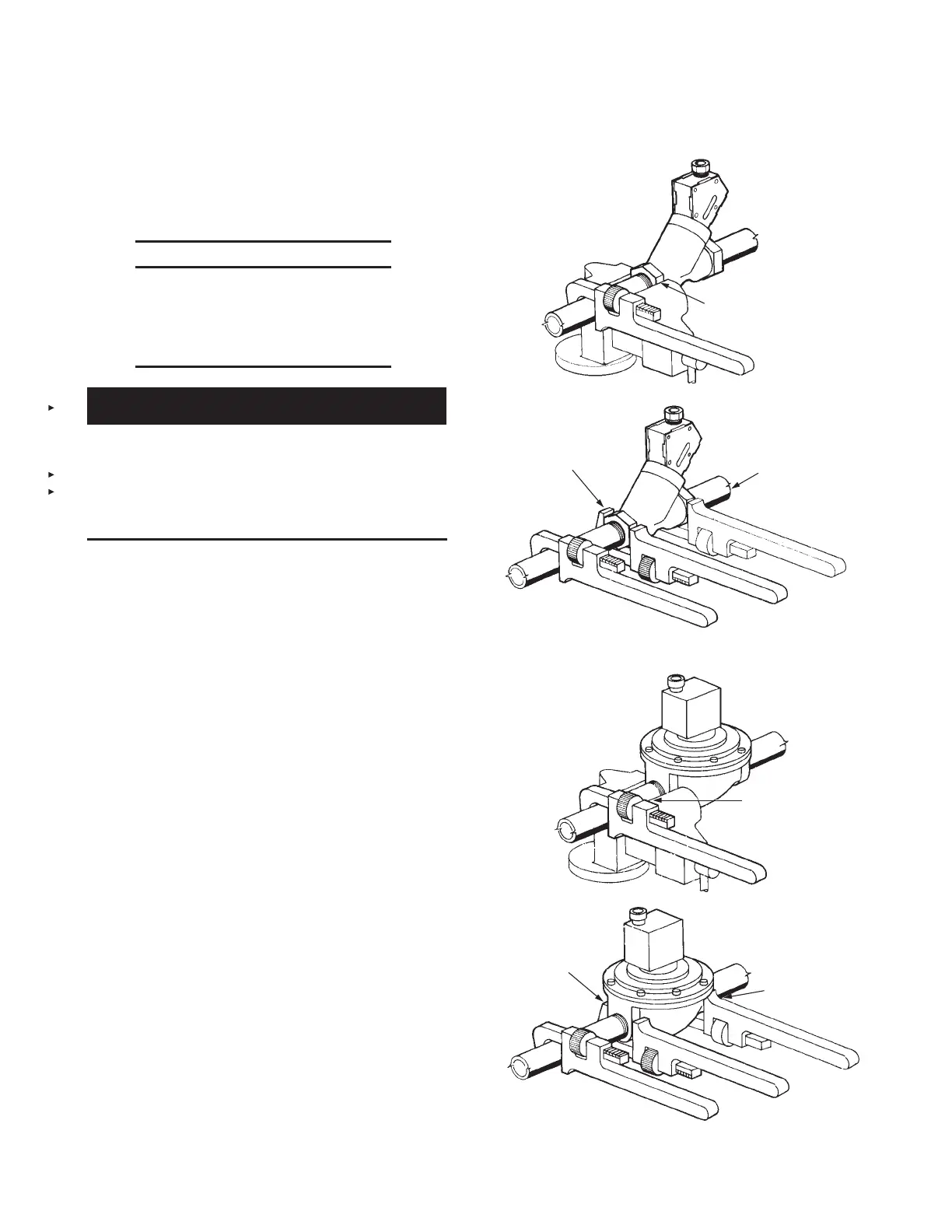

ASCO MECHANICAL GAS VALVES

000345

CORRECT WAY:

VISE GRIP APPLIED NEXT

TO PIPE BEING INSERTED

PREVENTS EXCESS

STRAIN ON VALVE BODY.

CORRECT WAY:

WRENCH APPLIED NEXT

TO PIPE BEING

INSERTED. PREVENTS

EXCESS STRAIN ON

VALVE BODY.

WRONG WAY:

WRENCH APPLIED AT

THIS POINT STRAINS

VALVE BODY.

000346

FIGURE 5-46

Loading...

Loading...