Error handling

Instruction handbook b maXX BM4400, BM4600, BM4700

Document No.: 5.12008.07 Baumüller Nürnberg GmbH

254

of 358

9.4

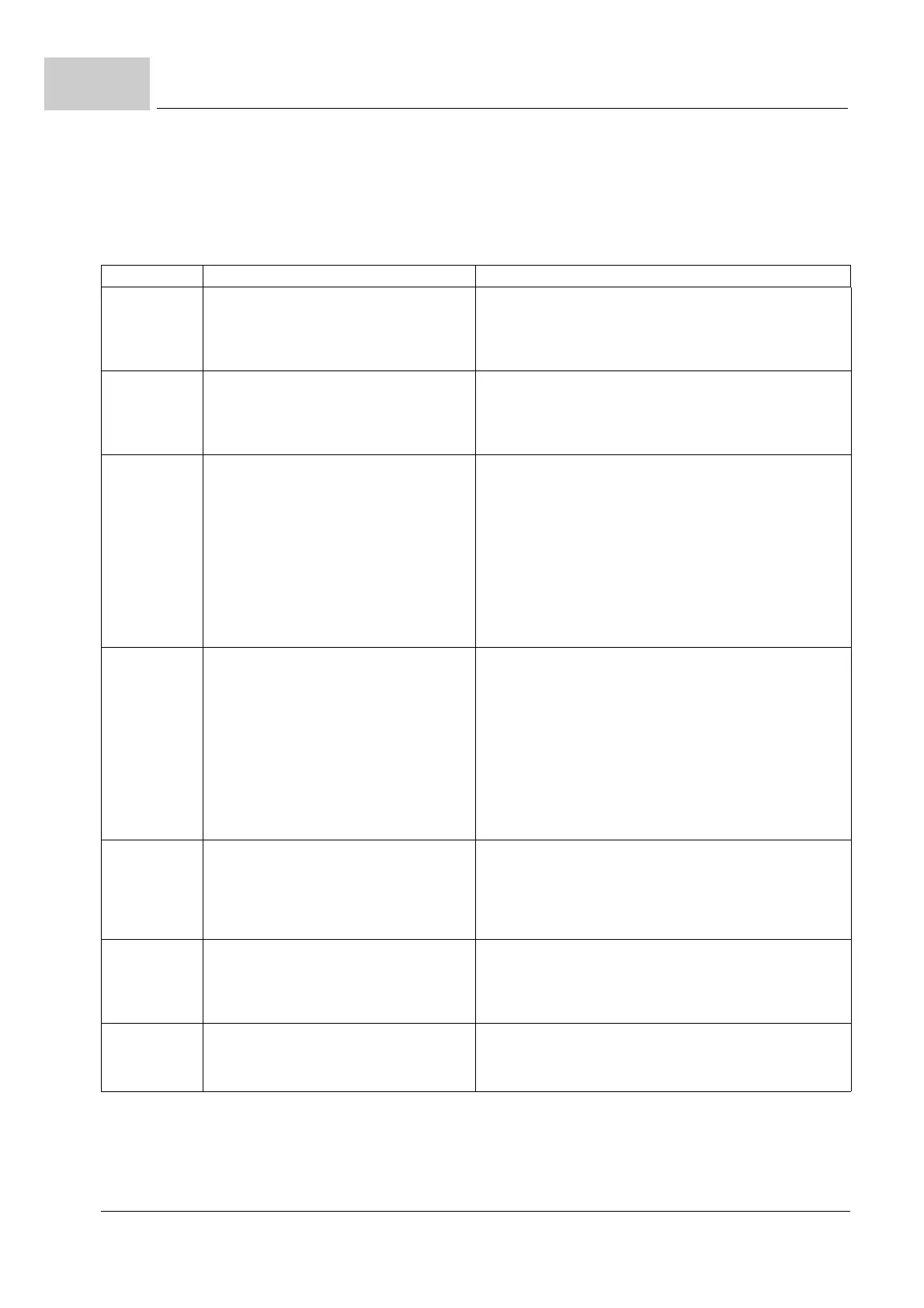

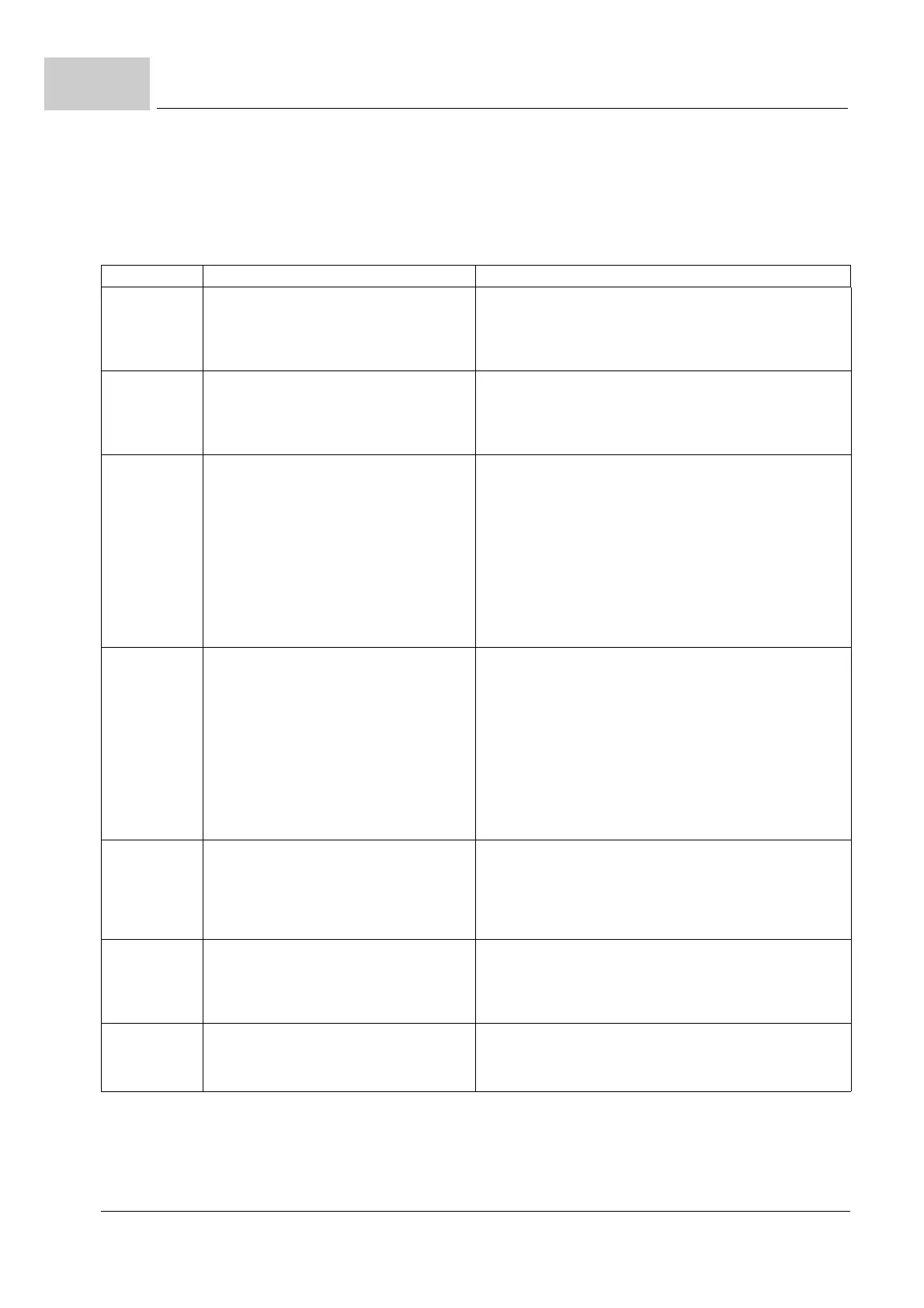

P0237 Error at finding notch position

If the function finding notch position is not completed without error, the motor error 102,

group error finding notch position is generated.

In this case the following parameter P0237 specifies the error in detail.

Error code Meaning Troubleshooting

1 Overcurrent step 1

m Error occurs at 180 % of maximum current

P1241

Find notch position method 2:

m Either allow higher current,

increase peak current P1241,

m or impress less current,

reduce amplitude of voltage P2122 (or P2148).

2 Overcurrent step 2

m Error occurs at 180 % of maximum current

P1241

Find notch position method 2:

m Either allow higher current,

increase peak current P1241,

m or impress less current,

reduce amplitude of voltage P2123 (or P2149).

4 Plausibility step 1

m Find notch position method 0, 3:

Current is too low or shaft is too immovable or

the direction of the rotating field P0087 is

wrong.

m Find notch position method 2:

Following controller does not converge to a

steady rotor position (the following controller

should calculate the same value from differ-

ent start values with unchanged rotor posi-

tion)

Find notch position method 0, 3:

m Check amplitude of current, the movability of the shaft and/or the

direction of phase rotation P0087.

Find notch position method 2:

m Increase gain of the following controller P2124 (preferred)

or/and

increase amplitude of voltage P2122 (or P2148). If P2122 (or

P2148) is at maximum already, then reduce the frequency of the

current P2120.

8 Plausibility step 2

m Find notch position method 2:

The measured part of the 2nd harmonic

(P2147 from FW 3.10) is less than the mini-

mal level P2125.

m Find notch position method 3:

Drive shaft moves more than 180 °

Find notch position method 2:

m Increase amplitude of voltage P2123 (or P2149). If P2123 (or

P2149) is at maximum already, then reduce the frequency of the

current P2121.

m If the current is at maximum, then reduce minimum level P2125

(attention: the stability of this method is reduced when setting

the minimal level too low.

Find notch position method 3:

m Decrease amplitude of current and/or check direction of the

rotating field P0087.

32 Timeout Find notch position method 1:

m Try method 3

Find notch position method 3:

m Increase current rising P3021 and/or decrease waiting time

P2127.

64 Drive moved more than 4 times traverse angle Find notch position method 3:

m Increase the maximum traverse angle P2128 (drives with high

friction, cogging torque, initial break away torque)

m Reduce current increase P3021 and/or speed delta rho P3022

(drives with negligible inertia/friction)

512 Plausibility step 2.

test invalid (from FW 03.10)

m The amplitude of the injected signal is too low

to detect the 2nd harmonic

Find notch position method 2:

m Increase amplitude of voltage P2123 (or P2149). If P2123 (or

P2149) is at maximum already, then reduce the frequency of the

current P2121

Loading...

Loading...