Pump Maintenance

Page 72 Auto Syringe AS50 Infusion Pump Operator’s Manual 07-19-B3-430

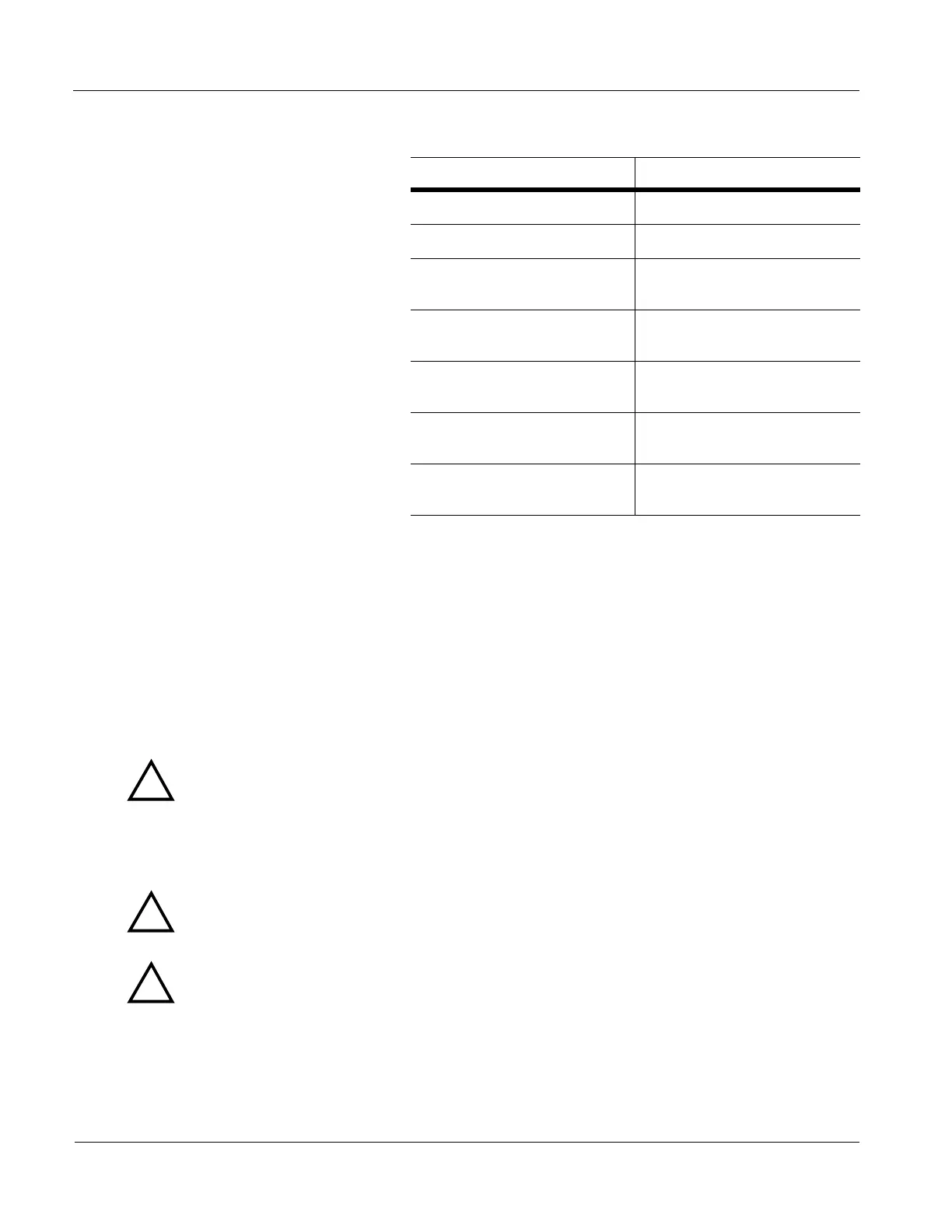

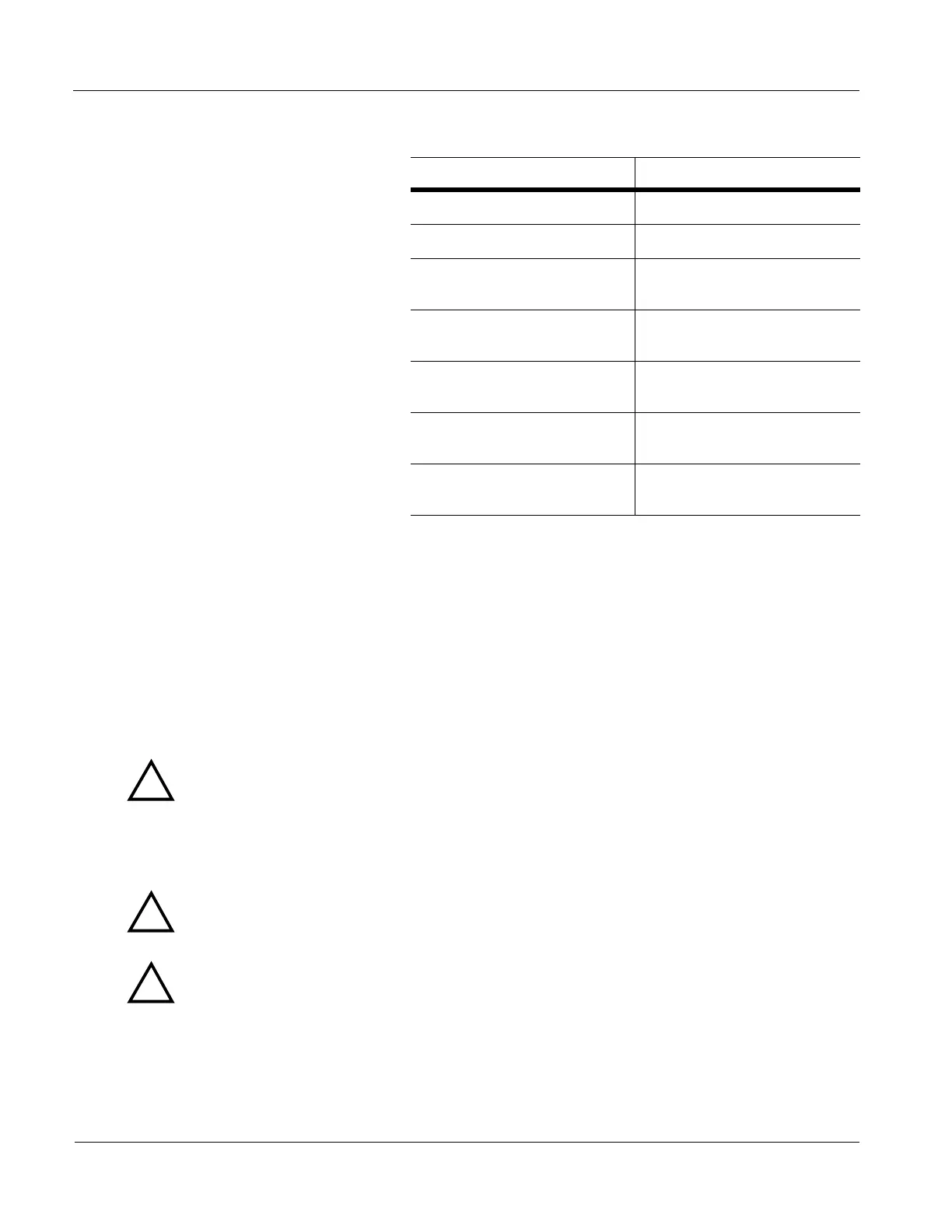

Acceptable cleaning or disinfecting agents are:

Note: Follow the manufacturer’s dilution instructions for concentrated cleaning and disin-

fecting agents.

Recommendation of the above cleaning or disinfecting agents is based on their

compatibility with the materials of which the pump is constructed. No representa-

tion is intended as to the effectiveness of any cleaning agent.

Surfaces to be disinfected must be free of gross (visible) foreign matter. Cleaning

the device before disinfection is recommended.

Some surfaces are not accessible with the above method. If spillage has

occurred onto inaccessible surfaces or into the mechanism, the device

should be Service Cleaned as soon as possible. Service Cleaning

methods are described in the Auto Syringe AS50 Infusion Pump Service

Manual.

Attempts to clean or disinfect internal parts, autoclaving or sterilization

by ethylene oxide gas will damage the pump and void the warranty.

Do not use the following chemicals on the device, as they will damage

the front panel: acetone, acetoaldehyde ammonia, benzene,

hydroxytoluene, methylene chloride, and ozone, Do not use cleaners

containing n-alkyl dimethyl ethylbenzyl ammonium chloride unless they

appear in the list of recommended cleaners in the Pump Maintenance

section of this manual.

Cleaner Manufacturer

Soapy water Various

Isopropyl alcohol Various

10% solution of chlorine

bleach and water

Commercially available

ASCEND germicidal

detergent

Huntington Professional

Products

Cidex Formula 7 sterilizing

and disinfecting solution

Johnson & Johnson

LpHSE, Septisol

germicidal

detergents

Steris Corporation

TOR, Hi-Tor Plus germicidal

detergents

Huntington Professional

Products

!

!

!

Loading...

Loading...