1 689 975 233 2018-05-08| Robert Bosch GmbH

54 | EPS 708 | Repairen

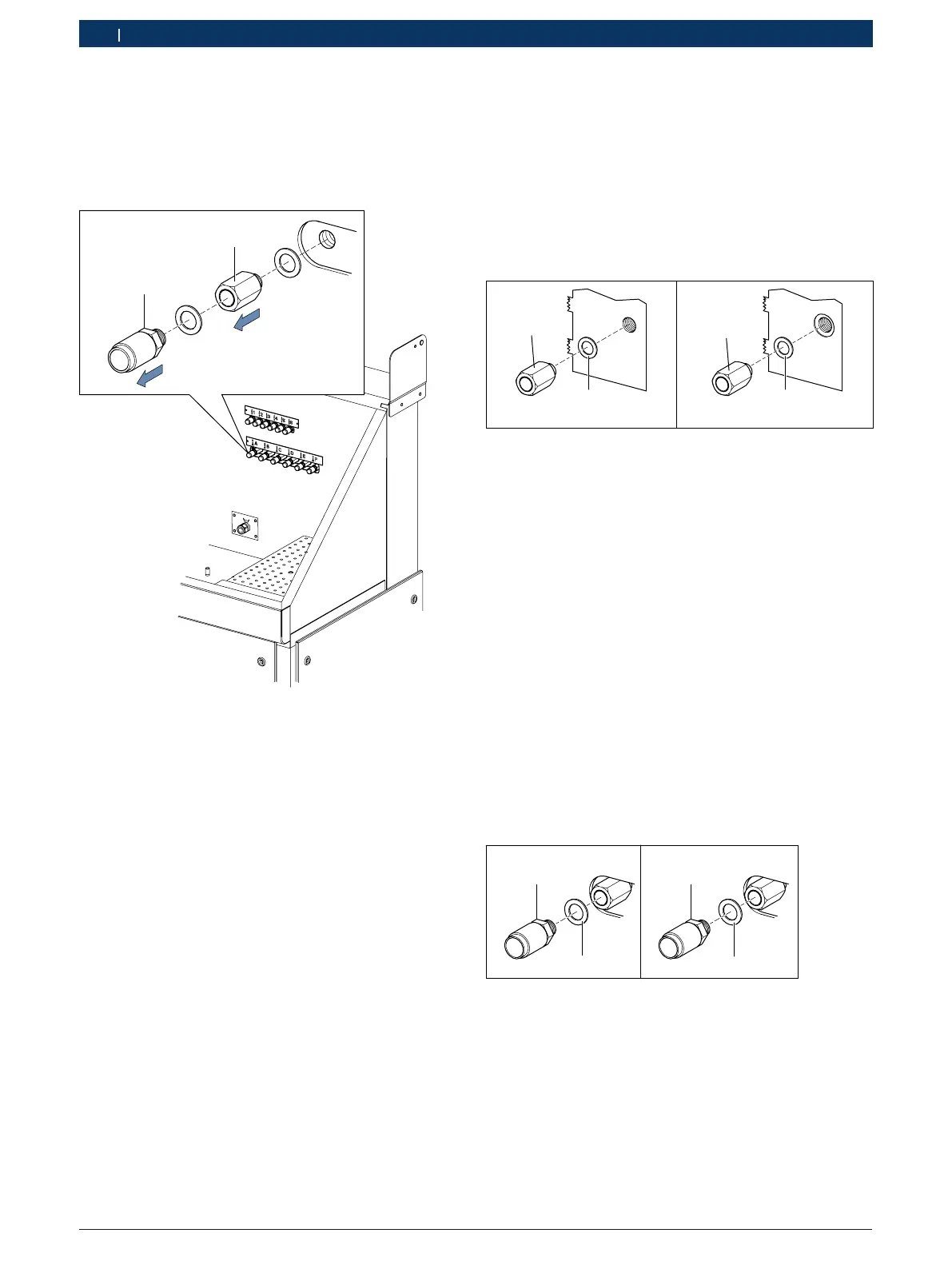

6. Remove the hose coupling (Fig. 92, item 1). When

loosening the hose coupling, hold the connection

fitting (Fig. 92, item 2) securely with a wrench. Do

not tighten the connection fitting further under any

circumstances.

7. Remove the connection fitting (Fig. 92, item 2).

1

2

Fig. 92: Removing the hose coupling

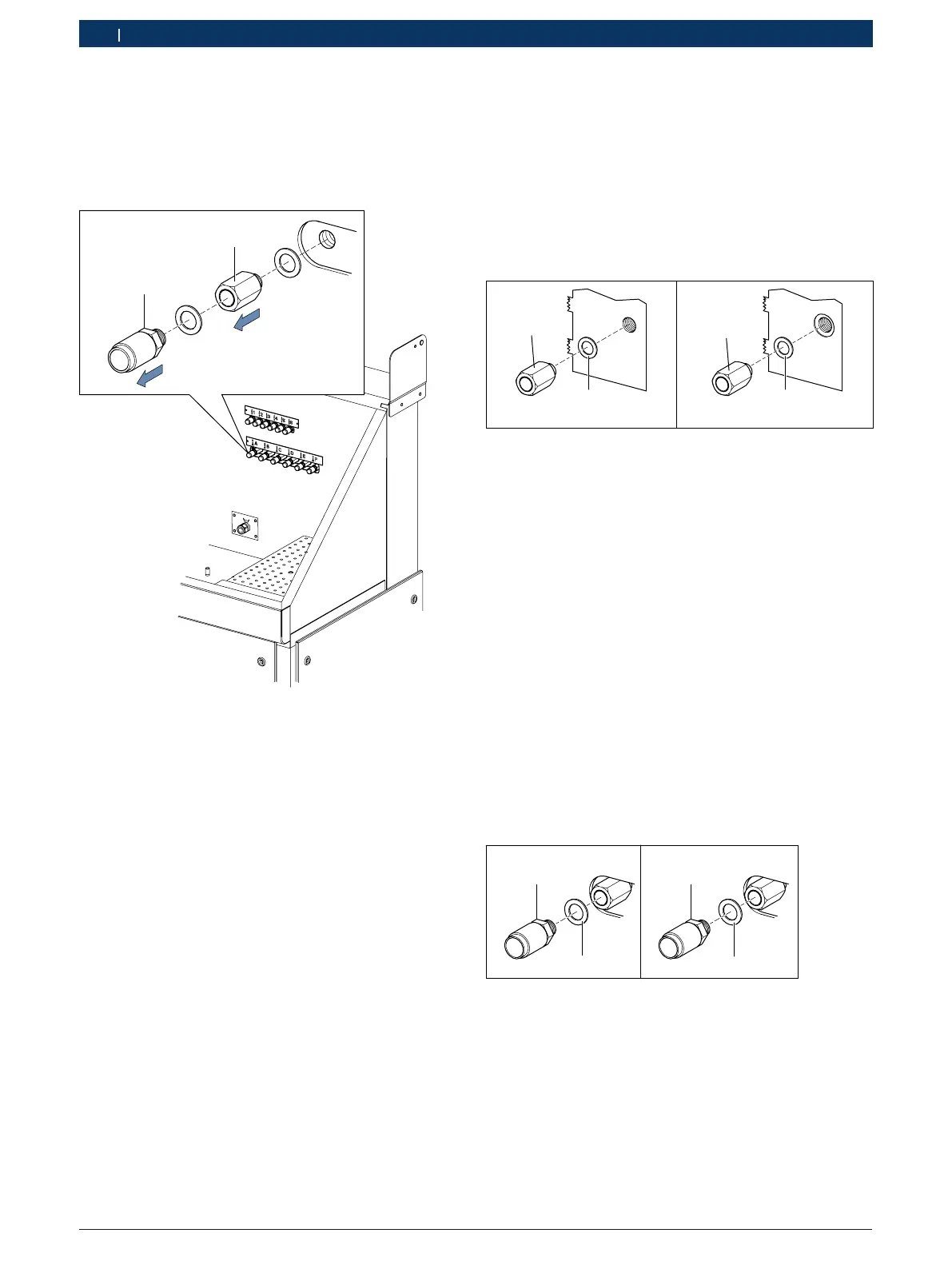

! Use the correct tightening torque (see Fig. 93) when

tightening the connection fitting. An incorrect tigh-

tening torque can damage the sealing ring or strip

the threads of the connection fitting. The tightening

torque depends on the sealing ring material (fiber

sealing ring or copper sealing ring). A copper sealing

ring can be used only if the hole in the valve body is

countersunk (spot faced).

1

2

max. 6 Nm

15 +2 Nm

458863-82_Pal

Fig. 93: Tightening torque

1 Fiber sealing ring 1 680 206 027 for valve body without counter-

sunk hole

2 Copper sealing ring 2 916 710 605 (A10 x 13.5 x 1) for valve

body with countersunk hole

8. Screw the connection fitting with sealing ring into

the valve body and tighten it. Observe the tightening

torque.

! Always use a new sealing ring when installing the

hose coupling. The new sealing ring must be made

of the same material (fiber or copper) as the one

just removed. If a sealing ring of a different material

is used, the connection will not be tight because of

an incorrect tightening torque or the sealing ring will

be damaged by the connection fitting. The tighte-

ning torque (see Fig. 94) depends on the sealing

ring material (fiber sealing ring or copper sealing

ring).

4588863-77_Pal

max. 6 Nm

15 +2 Nm

1

2

Fig. 94: Tightening torque

1 Fiber sealing ring

2 Copper sealing ring

9. Screw in and tighten the hose coupling with sealing

ring. Observe the tightening torque.

Loading...

Loading...