1 689 975 233 2018-05-08| Robert Bosch GmbH

Repair | EPS 708 | 73 en

6.38.2 Fitting pressure sensor B4

1. Lubricate O-ring on the new pressure sensor with

test oil.

2. Push pressure sensor into sensor block.

3. Fasten pressure sensor with fastening screws (2x)

and washers (2x).

Tightening torque: 5 +1Nm

4. Connect connection cable to pressure sensor B4.

5. Fasten cover on the hydraulics chamber

(see Fig. 7, item1).

6. See section 10.2 to perform zero point adjustment

for pressure sensors.

7. See section 6.38.3 to perform temperature adjust-

ment (only with retrofit kit CP4).

6.38.3 Adjusting temperature sensors

1. Switch on the EPS 708 at the master switch.

2. Start the EPS945 system software.

The software performs initialization

3. In the "Injection component test main menu" start

screen, select <F7>.

A password request appears.

4. Enter the password in the input line: 1958

5. Confirm your entry with <F12>.

6. Select menu item "Calibration >> Delta tempera-

ture".

7. Continue with <F12>.

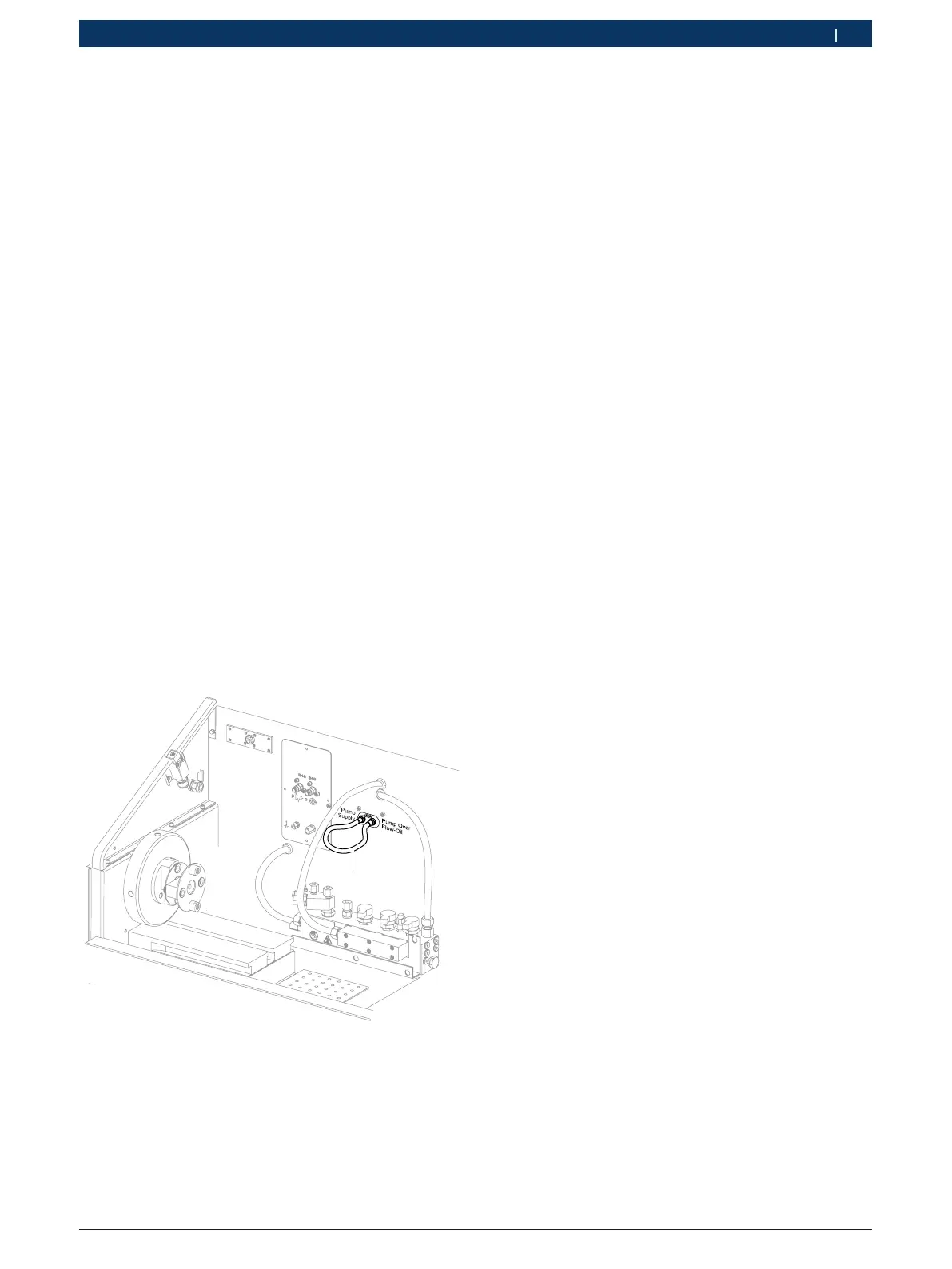

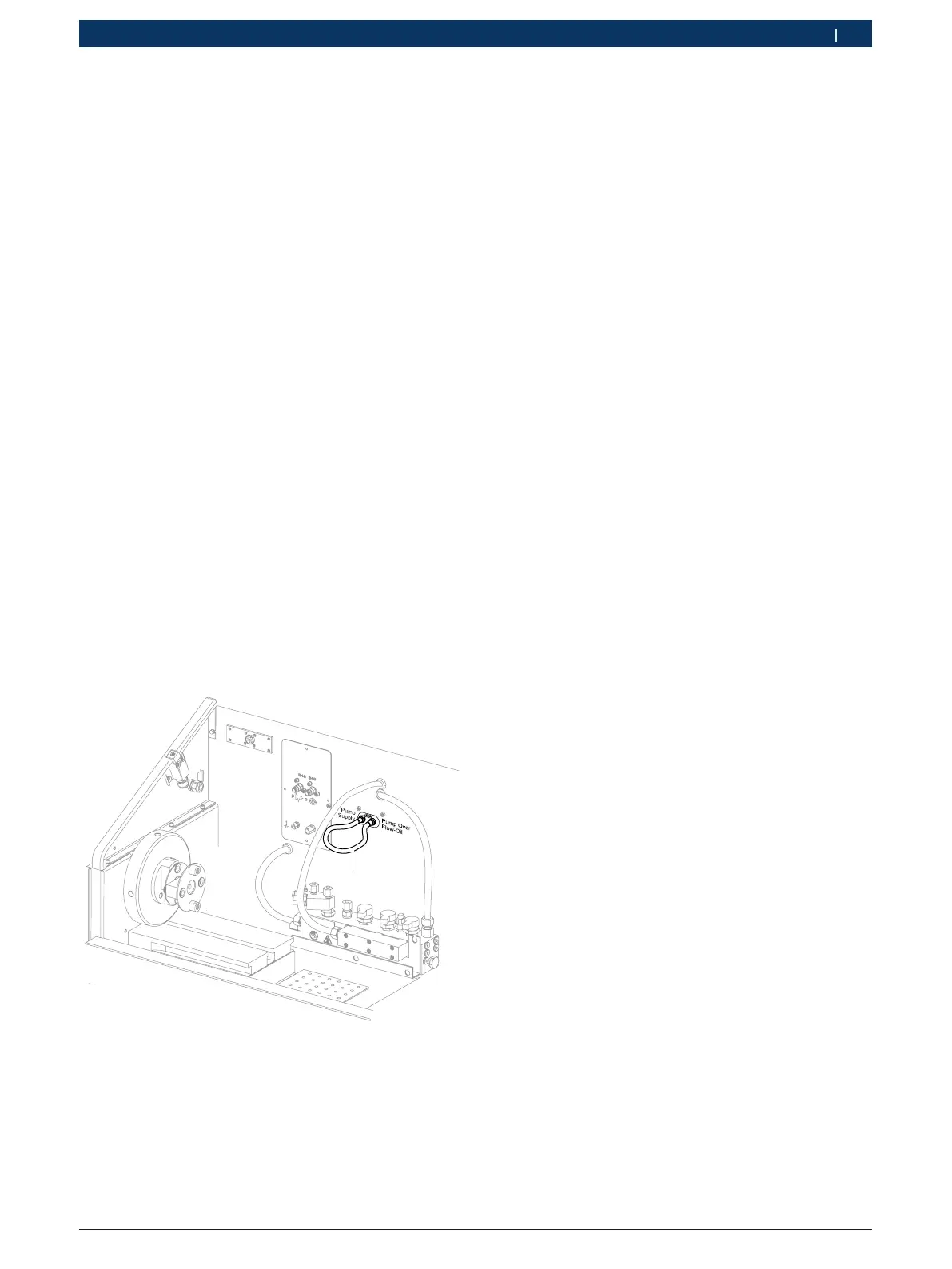

8. Connect the test oil supply connection via hose

assembly 1680712363 (Fig. 139, item1) with test

oil return connection of the EPS 708.

X22

1

458895-17_Pal

Fig. 139: EPS 708 with hose assembly 1680712363

9. Close the protective cover.

10. Set pump supply pressure with <F3> or <F4> to

20kPa.

11. Set pump return pressure with <F3> or <F4> to

20kPa.

12. Start low-pressure control with <F8>.

Pump supply and return pressure is started.

13. Check the actual values listed in the EPS945 soft-

ware for the temperature difference of the pump

supply and return.

14. As soon as the temperature difference for the pump

supply and return has reached the desired value (set

to 40°), select <F2>.

The temperature sensors were adjusted.

15. Press <F8>.

16. Exit the configuration menu by pressing Esc twice.

" This completes the temperature adjustment.

Loading...

Loading...