71

9.3 Cleaning the Print Head

9.3.1 Unclogging a Clogged Nozzle

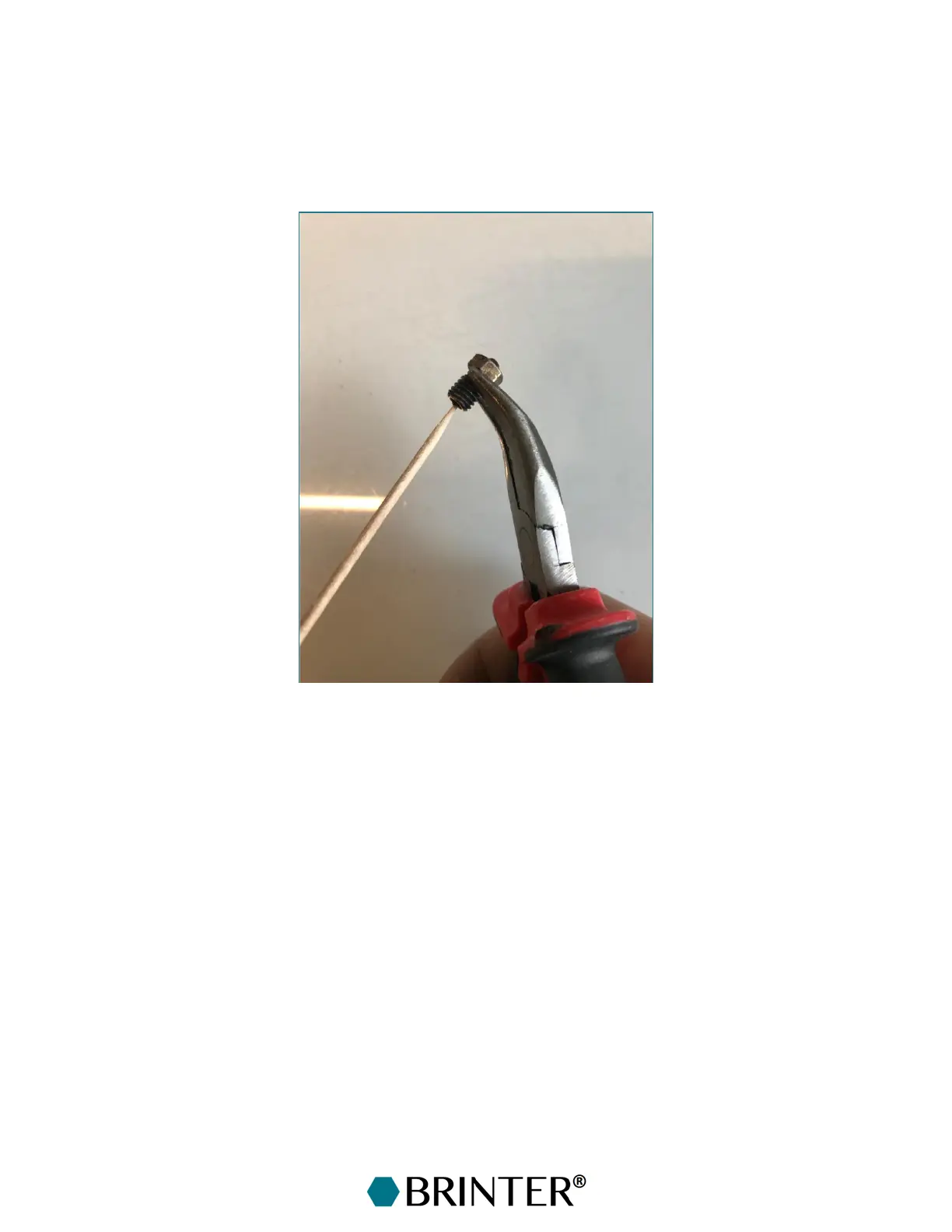

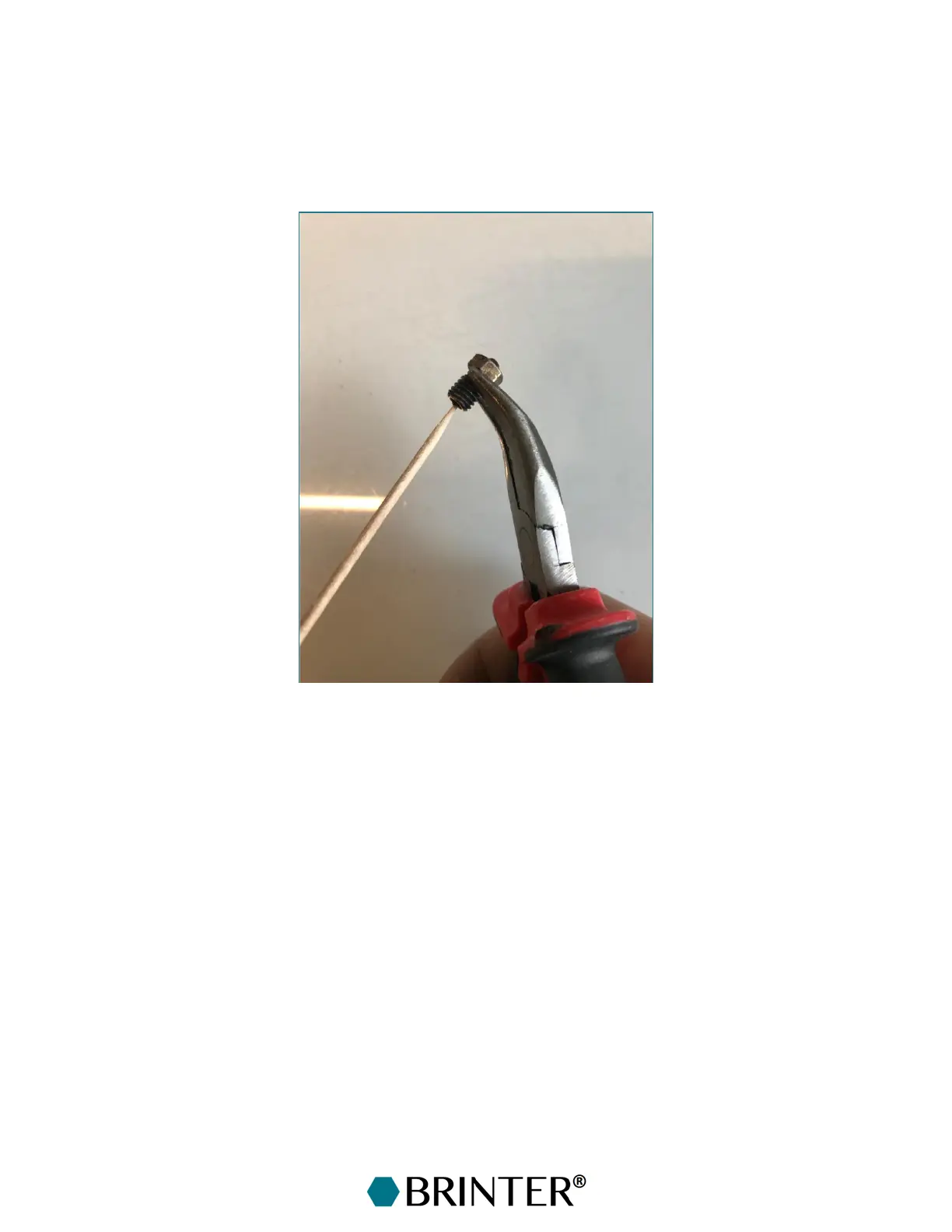

In the case of clogging in the nozzle (Figure 8), you can try to unclog it while having it still in its place

by sticking a small metal wire in the nozzle opening. If this is not successful, the nozzle can be placed

on fire for a few secs and then try to clean it with a wooden toothpick.

9.3.2 Cleaning the Granu Tool with ASACLEAN™ Purging Compound

The easiest way to clean material residue from the Granu Tool print head is to use special purging

compounds, such as ASACLEAN™ Purging Compound, U Grade.

First, let the extrusion barrel run empty of the old material.

Next, dose pure ASACLEAN™ into the hopper and push the purging compound through the print head

until ASACLEAN™ comes out of the nozzle.

Check the working temperature for your ASACLEAN™ grade from the ASACLEAN™ brochure and let

the ASACLEAN™ sit in the barrel according to the instructions. For ASACLEAN™ U grade, the

processing temperature is from +180°C to +330°C, and the ideal residence time is 3–5 min.

Push the material out of the barrel at low speed. Extrude until the contamination is thoroughly

flushed out. Be aware of possible increases in pressure within the barrel.

Reset the parameters.

Finally, fill the new polymer into the hopper and start the next print job.

Loading...

Loading...