77

11 Appendix 6. Pneuma Triaxial Pro Tool Manual

11.1 Print Head Overview

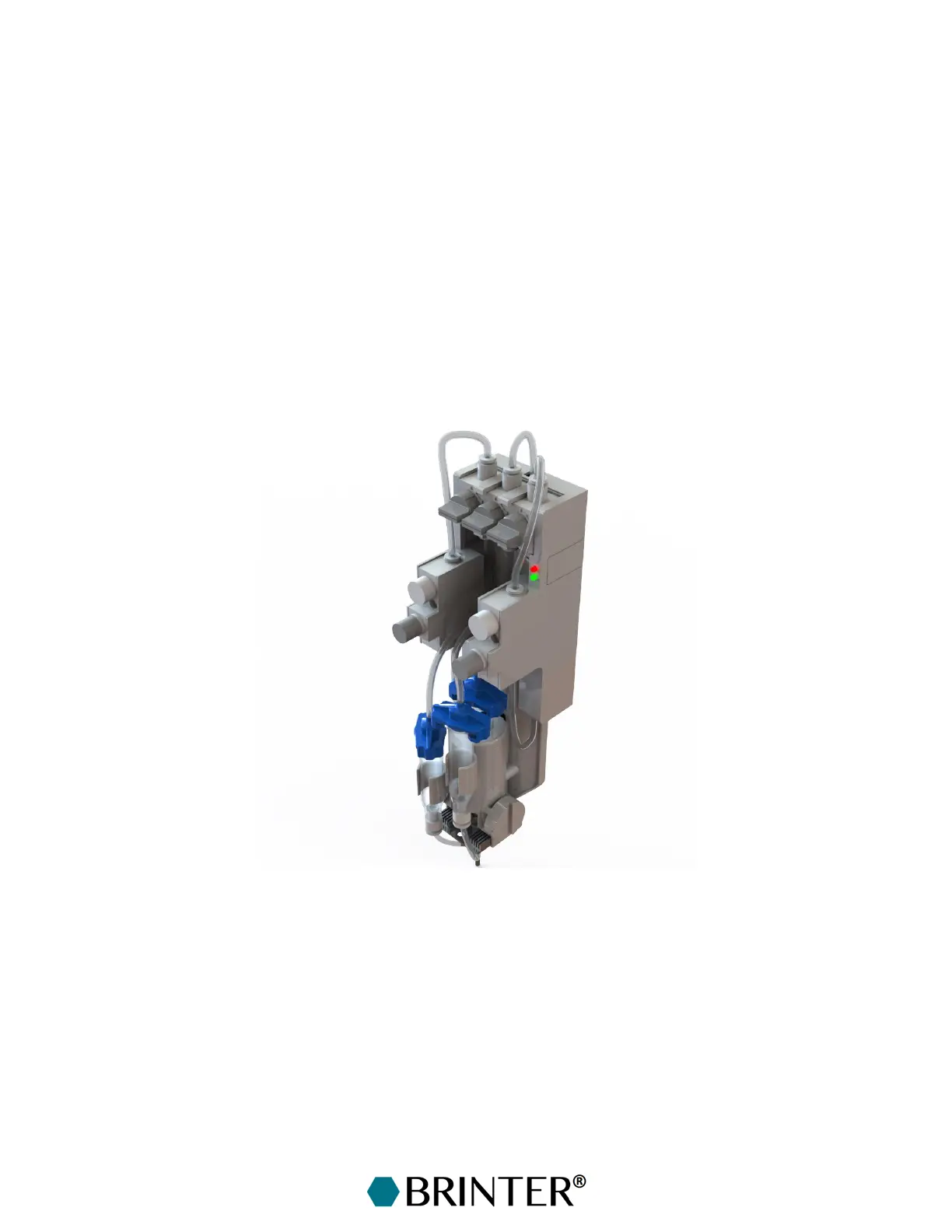

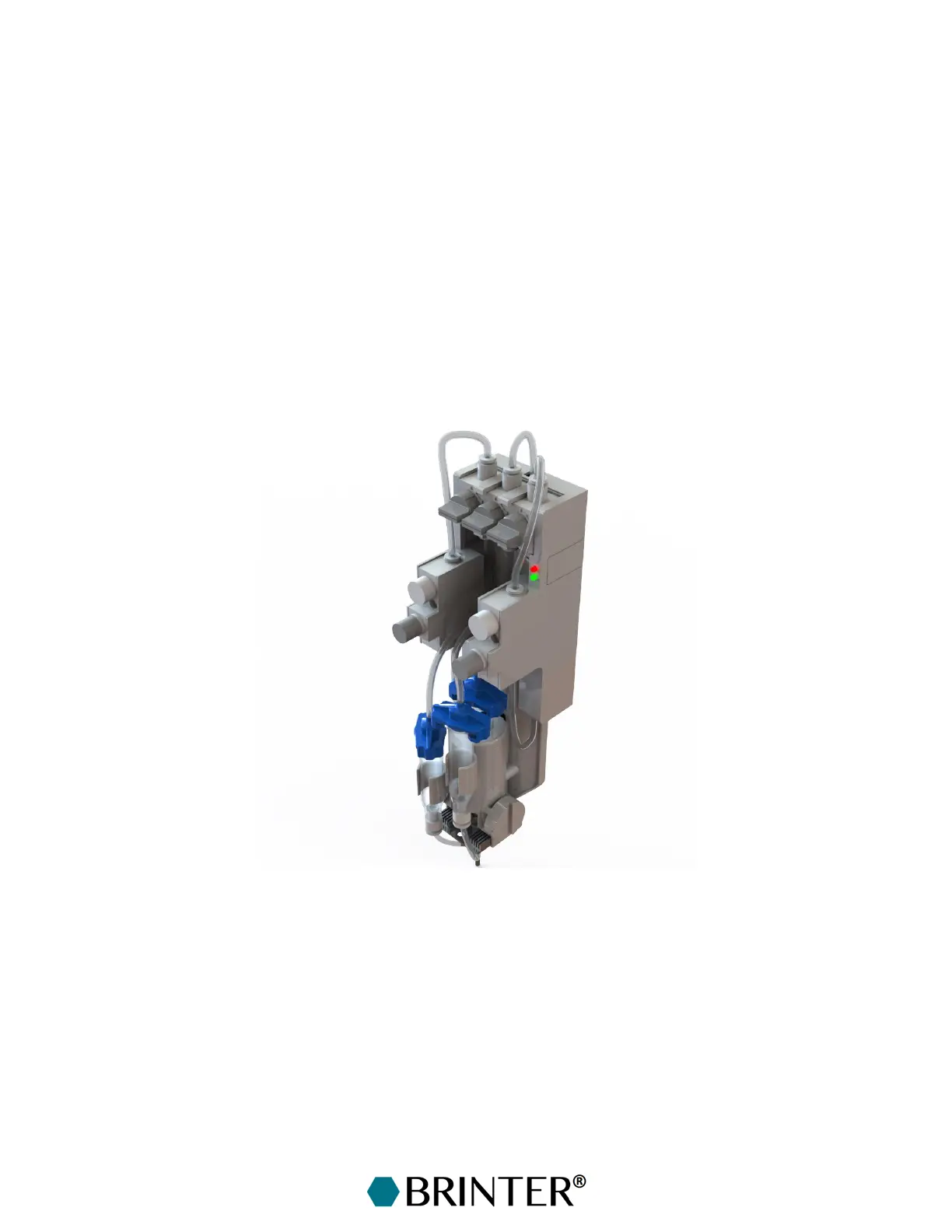

The dispensing with the Pneuma Triaxial Pro Tool print head (Figure 10) is based on the pneumatic

extrusion. The triaxial needle enables the printing of up to three different materials simultaneously,

i.e., the core material, intermediate material and the outer shell material.

The print head has a heating function enabling a constant temperature from RT to +66 °C in the

biggest syringe barrel (10 mL). In addition, the print head is equipped with an integrated UV/Vis LED

module emitting at a wavelength of 365 nm, 405 nm or 450 nm. It allows in situ photocrosslinking

of the photosensitive non-viscous bioinks during the deposition process. Pneuma Triaxial Pro Tool is

compatible with various commercial and noncommercial low-to-medium viscosity hydrogel bioinks

and pastes; however, if the printed material breaks the tool, it is not covered by the warranty.

The standard sizes of the triaxial needle channels are as follows: the innermost needle 26 G

(I.D.=0.254 mm), the middle needle 19 G (I.D.=0.690 mm) and the outer needle 15 G (I.D.=1.37

mm). In the standard design, all the needle tips have the same length. Custom needles with other

inner diameters and tip lengths can be delivered according to a request.

Loading...

Loading...