59

Although stability detection settings are optimized at default, they can be changed as

instructed in 11.3.2 and 11.3.3 depending on specific measurement requirements.

Functions that use stability detection

Auto Print (See 13.3), Auto Zero (See 13.4), Taring/Printing at Stability (See 13.6), Peak Hold

(See 14.3), Auto-Memory and Zeroing (See 14.5), Animal Weighing (See 14.6), Formulation

Mode (See 14.7).

Stability mark is an auxiliary device to inform measurement stability. The displayed

value may change while the stability symbol remains illuminated if the load is

changing slowly, or depending on the stability detection settings.

11.3.2 Stability Detection Band

This setting is effective on both stability mark illumination and on operations triggered by

stability detection.

The default setting is 1 count.

If stability detection band is “1 count”, the measurement is regarded to be stable when the

display has remained within one display count for a certain fixed length of time. If stability

detection band is “2 counts”, it is regarded to be stable when the display has remained within

two display counts. Selecting a larger stability detection band makes stability detection take

place before the display converges into 1 count.

Try a larger stability detection band when data output triggered by stability detection is

delayed due to environmental conditions of the installation site. Data output and auto zeroing

can then be made more efficiently.

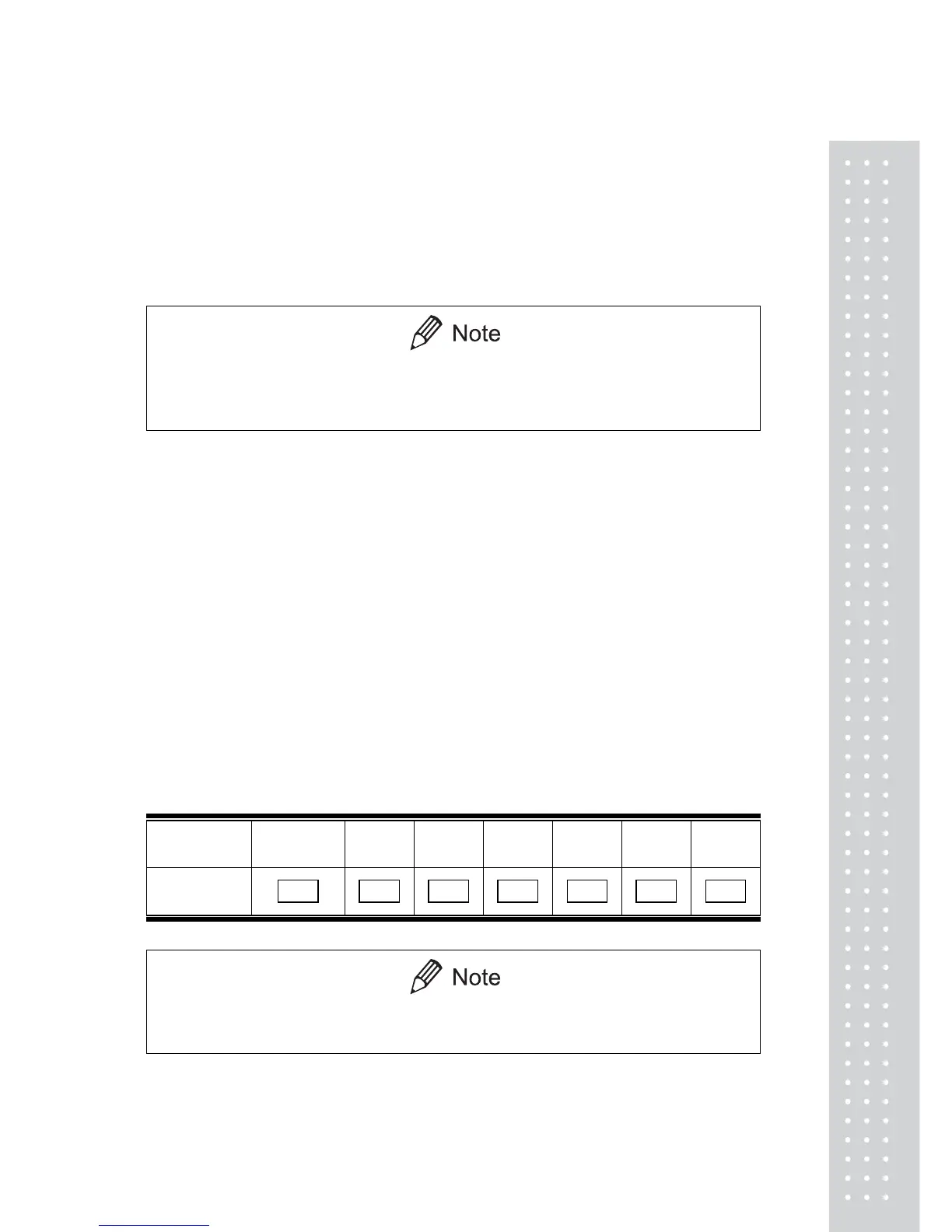

Stability

detection band

1 count

(default setting)

2 counts 4 counts 8 counts 16 counts 32 counts 64 counts

Menu item

number

27

28

29

31

32

33

34

Use “16 counts” to “64 counts” for Auto Print, Animal Weighing or other data-

utputting function under very unstable conditions only.

Loading...

Loading...