1-7

OPERATOR’S MANUAL PRO SERIES

1 GENERAL DESCRIPTION

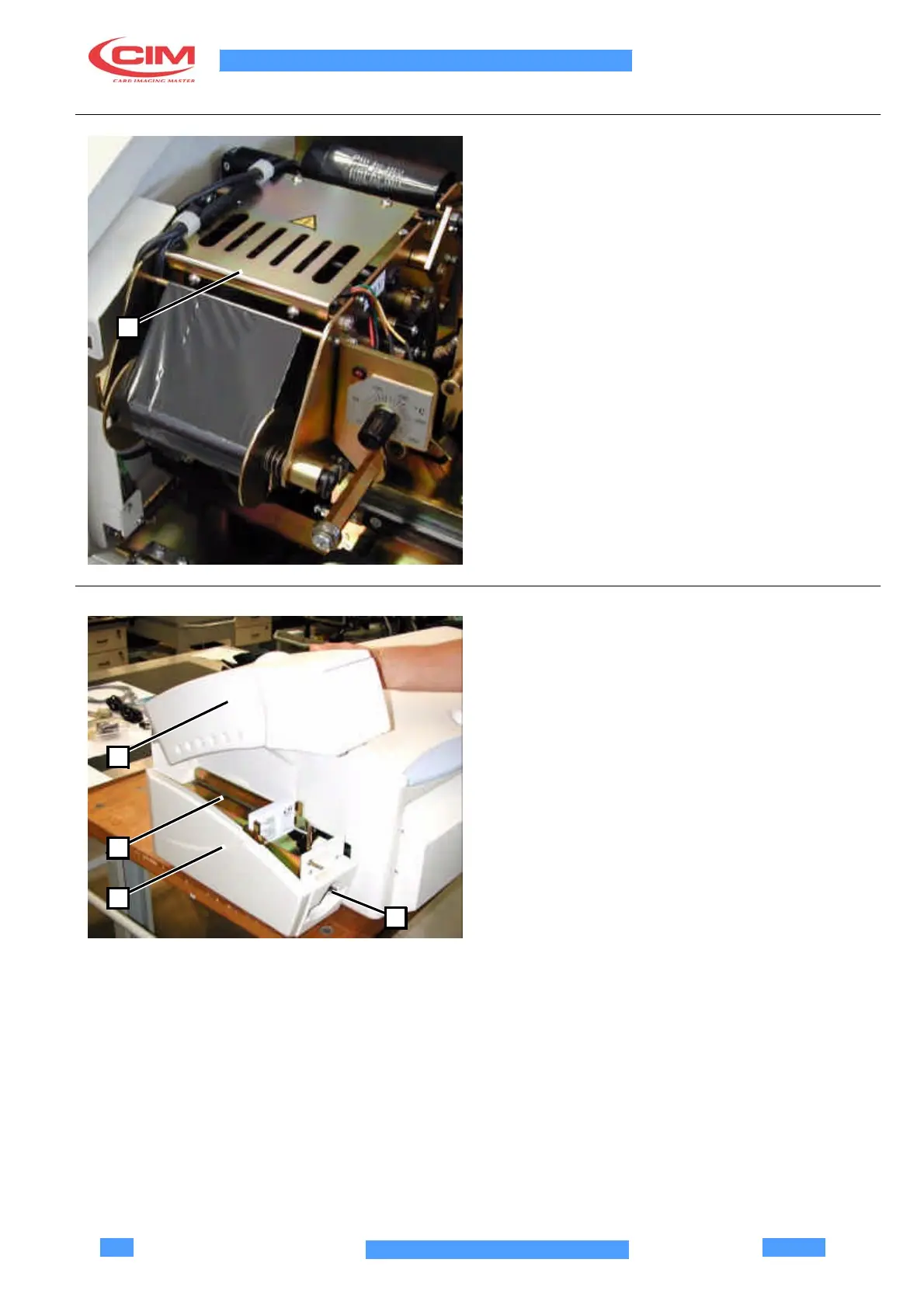

1.8 TIPPER

The Tipper is a device which inks the embossed

characters.

The Tipper Unit has a Hot Silicon Blanket (160°-170° C)

which, when pressed on the inked ribbon placed

between the card and the Silicon Blanket, transfers the

ink onto the embossed characters.

The working temperature can be set by turning the

graded knob which is located on the left of the ribbon.

1

On switching on the machine it is necessary to wait at

least 5 minutes so that the Tipper can heat up and reach

the working temperature. Any calls for the Tipper before

it is ready will generate an error message: “E-19

TIPPER NOT READY-PLEASE WAIT” to signal that the

system is not ready to ink.

When the Tipper has reached the working temperature

it will produce the card without needing any input from

the operator.

The maintenance instructions should be carefully noted

in order to obtain the correct functioning of the Tipper .

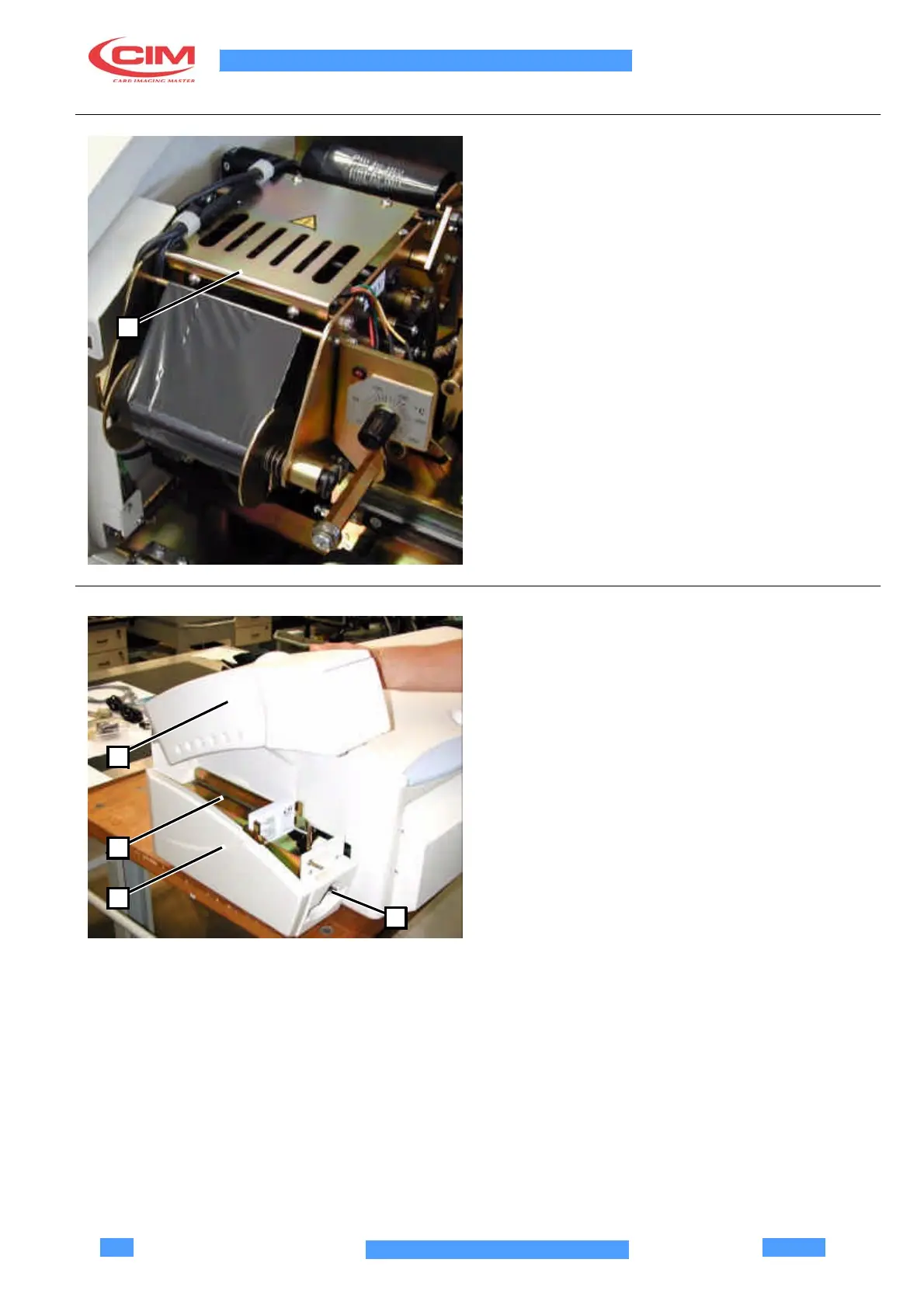

1.9 UNLOADING UNIT

The unloading unit (3), with removable cover (1), allows

to extract the cards.

The cards successfully produced are stored in the upper

part (2) of the unit, while the defective ones are placed

in the lower part (4).

The moving guide allows to store the cards without

1

jamming. To function correctly, it must always be put in

position “fully forward”. On the contrary, the alarm

“unloading not ready” would be generated.

The unloading unit is equipped with sensors which

2

detect if it is full or empty (negative and positive

unloader), generating the respective alarms.

3

4

Loading...

Loading...