1 GENERAL DESCRIPTION

1 - 4

OPERATOR’S MANUAL PRO SERIES

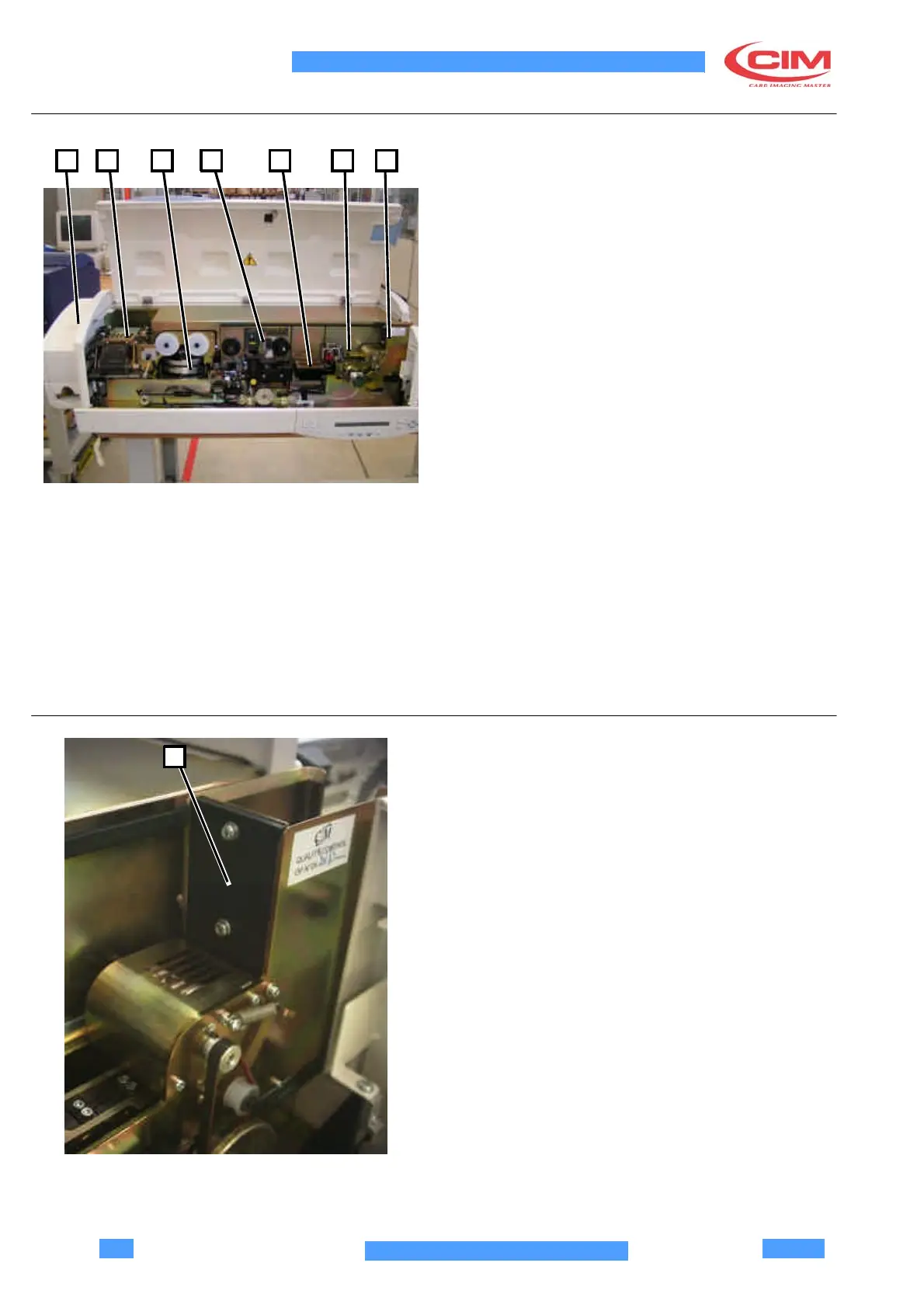

7 6 5 4 3 2 1

1

1.2 PRODUCTION CYCLE

The C 1000 PRO machine production cycle can be

divided up into the following phases.

1.

LOADING THE CARD: The card is picked up and

inserted in the encoding module.

2.

MAGNETIC ENCODING AND CHIP (OPTIONAL):

The card is encoded and read in only 2 steps on the 3

tracks in LO-CO (low coercivity) or HI-CO (high

coercivity) according to ISO 7811.

3.

FLIP-OVER STATION (OPTIONAL): For rotating the

card for double-sided thermographic printing.

4.

THERMOGRAPHY: May be monochromatic and/or

colour for printing logos and data on both sides of the

card.

5.

EMBOSSING: This can be done either by embossing

or indenting. During the indenting the Infiller will be

activated in order to ink the characters at room

temperature.

6.

TIPPING: When the card has been released by the

clamp the Tipper is activated and the embossed

characters are coloured.

7.

UNLOADING: The card is stacked in the unloader tray

or passed to the next PRO machine. If any error has

occurred during the production phase the card is

discarded in the Discard area and the machine stops

displaying an error.

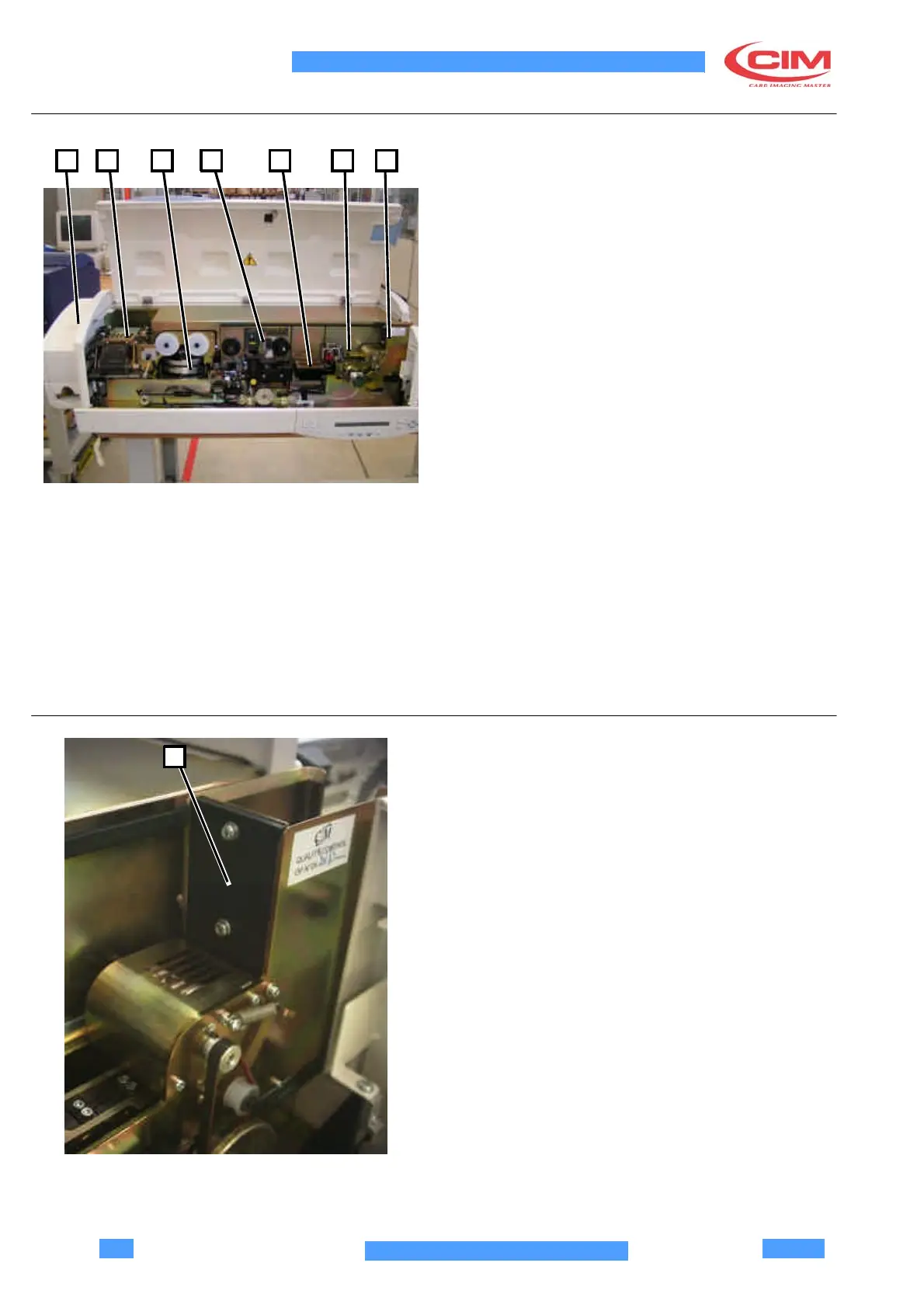

1.3 LOADING AND ENCODING UNIT

The loading unit (1) allows to store vertically 200 cards

0,76 mm thick. The card at the bottom of the pile is

picked up and moved to the working units. The bar code

encoding function can be integrated in the unit, in

accordance with the standards ISO and JIS (Japan). It

is possible to place here the chip contactor which allows

to read and write “contact” cards which comply with the

ISO 7816 standard.

Loading...

Loading...