6 TROUBLESHOOTING

6-

OPERATOR’S MANUAL PRO SERIES

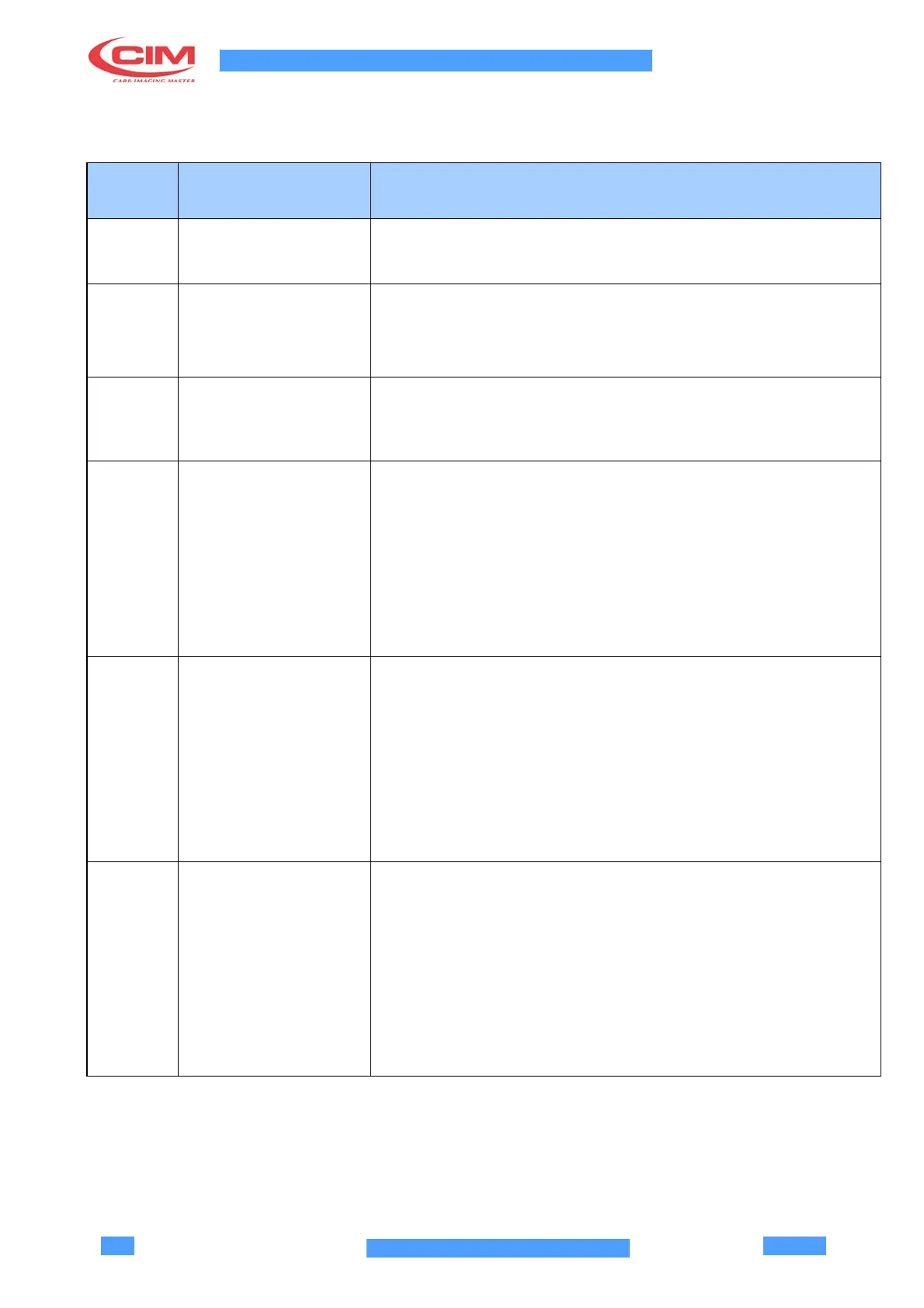

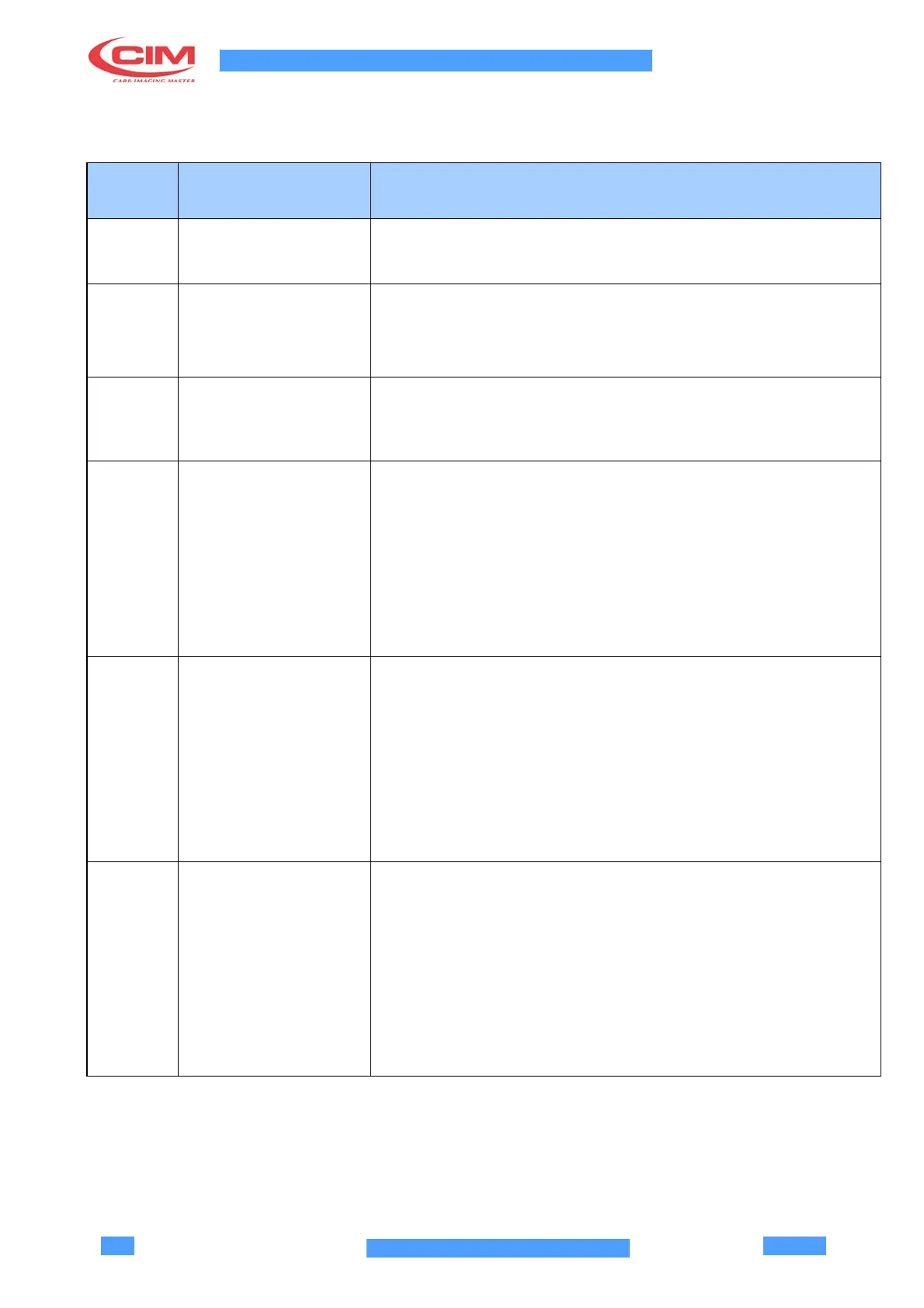

6.1 PROBLEMS AND SOLUTIONS

CODE MSG POSSIBILE INTERVENTO

E-00 POWER ON STAND BY

STATUS - PRESS

START

This message appears when the printer is turned ON and tells the

operator that the machine is powered up. To work, the operator must

use the software commands (RESET/PRINT).

E-01 OUT OF CARDS-

PRESS START OR

FEED

This message signals that the loader is out of cards. Add cards to

continue operation. However, if the loader does contain cards, check

photocell FC4/FC7 for proper operation, proper loading tooth movement

and proper regulation of the loading box guillotine.

E-02 CARD

MISFEED-

PRESS START

The paper has not come out of the coding unit or has not been loaded

by the gripper. Check the photocell FC4 and check that the cards are

not warped. Check that the gripper opens correctly and check that the

home photocell (FC1) is functioning correctly. Press FEED to try again.

E-03 PUNCH MOTOR

ERROR - PLEASE CALL

SERVICE

The punch motor has not performed a complete cycle. Check:

that punching pressure is not too high;

photocell FC5;

fuses on the logic card;

that the punch motor is running properly;

that the clutch engages;

that the brake does not remain engaged at the end of the cycle.

E-04 EMBOSS WHL ERR.-

CHECK CARD/PRESS

START

Signals that the “character” drum has not returned home. Check:

that there are no punches out of position and manually check that the

drum is completing a rotation of 360°;

that belt tension is not too tight or too slack;

that the position control disc is fitted correctly;

that photocell FC3 is working properly;

the logic card for malfunctioning (L298 motor drivers burned out or fuses

blown).

E-05 X MOTOR ERROR -

PRESS START

Signals a movement error on the carriage X axis. Check:

axis X photocells for proper functioning;

that there is nothing mechanical obstructing complete carriage strokes;

cleaning, lubrication and sliding on the guide;

proper toothed belt tension;

correct positioning of mechanical limit stops;

that the set-up parameter settings match those indicated on the card

and in the operator’s manual.

Loading...

Loading...