P/N 80679, Rev. 10 Page 35

Do not over tighten, as this

could bind the leveling feet

during leveling. Check that the

setup fingers are seated evenly.

Do not extend the jacking feet

past the full-extension groove in

the threaded screw (Figure 3-

13 on page 34). If needed, add

additional leg sections to

minimize the length of the threaded jacking screw that is exposed.

8. After securely attaching the machine to the flange, attach a dial indicator to the

turning arm.

9. Check that power to the machine drive is isolated and locked out.

10. Using the dial indicator, indicate the workpiece surface for level while

manually rotating the machine.

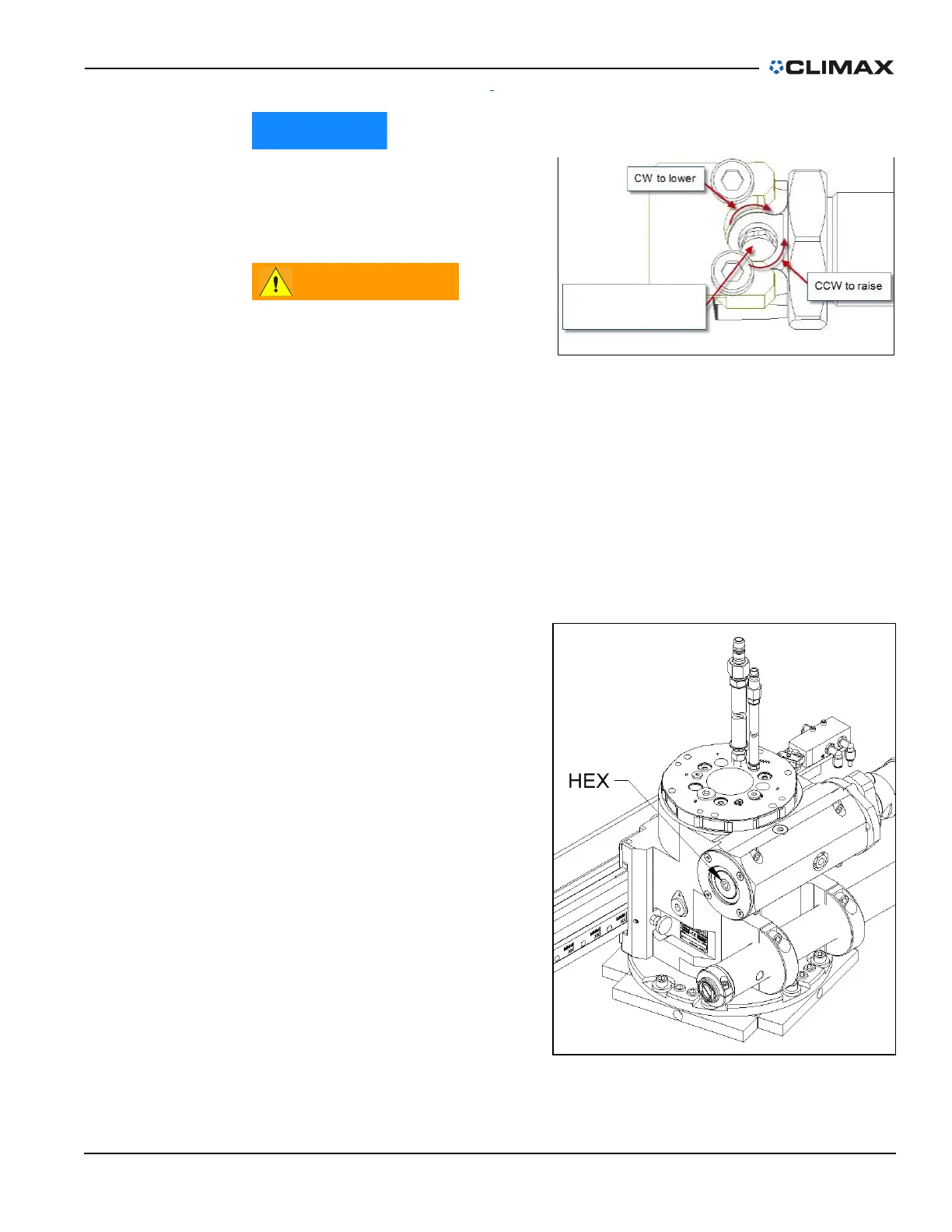

• To manually rotate the pneumatic machine, insert a 10-mm hex wrench in

the hex opposite the motor or push on the end of the turning arm.

• To manually rotate the

hydraulic machine, use the

cross-connection hose

supplied with the machine

to connect the #1 and #2

port hoses. Insert a 10 mm

hex wrench in the hex

opposite the motor or push

on the end of the turning

arm.

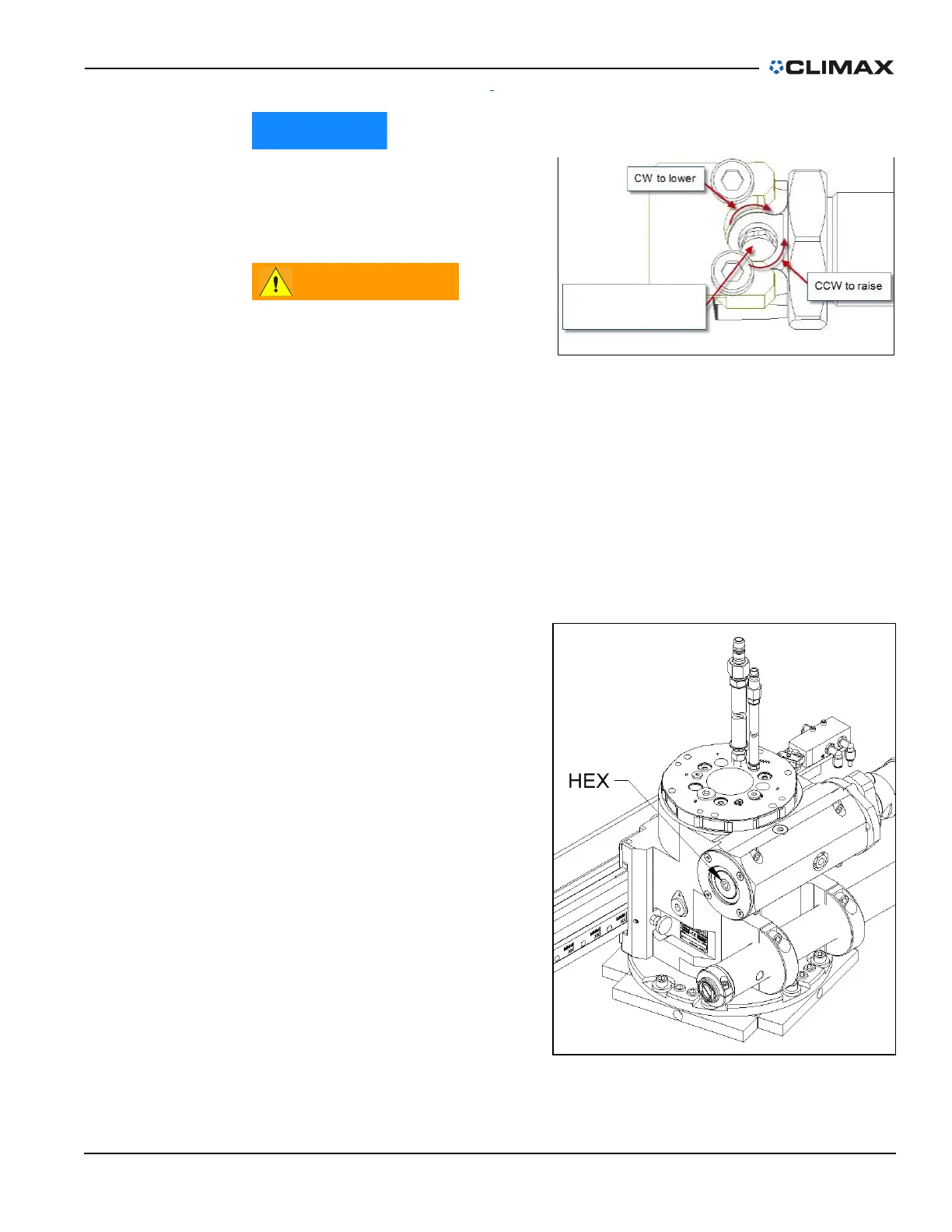

11. Level the machine by turning

the leveling screws in each of

the leveling feet with the dial

indicator close to leveling

adjustment (Figure 3-6 on

page 29).

12. Reposition the dial indicator

to check machine centering.

13. Center the machine by adjust-

ing opposing pairs of jacking

feet.

Leveling screw

(10mm

Hex wrench)

FIGURE 3-14. ADJUSTING THE SETUP FINGERS

FIGURE 3-15. LOCATION OF THE 10-MM HEX FOR MANUAL

ROTATION OF THE MACHINE

Loading...

Loading...